What’s new in Teamcenter Simulation Spring Release 2022? | Simcenter

It’s springtime – and do your thoughts naturally turn to SPDM (simulation process and data management) too?

An insightful quote can be a good way to start a blog, and there is certainly no shortage of quotes to choose from on the subject of springtime. Usually about things blossoming, people falling in love, and feelings of renewed hope after the harsh winter weather. I was struggling to find one introduce my topic of new features in the Spring release of Teamcenter Simulation (after all, despite the chilly weather, the fall release was actually pretty good too).

Then I read this one: To plant a garden is to believe in tomorrow.

For those that don’t know, Audrey Hepburn was not only a film and fashion icon but a dedicated gardener too. In fact, her last recorded performance was a documentary series on gardens in the 1990s. To me, this simple yet profound quote very succinctly describes how gardening is such a beneficial activity for human well-being. Not surprisingly, it turns out to be one of the most popular gardening quotes ever.

Is there any reason why it should not also become one of the most popular SPDM mantras too?

Growing the simulation and test ecosystem in Teamcenter Simulation

Audrey would probably be surprised to learn how the world of engineering software has appropriated the word ‘ecosystem’ to describe how different tools, personas and processes can live and work together on a central platform.

A flourishing and stable ecosystem is a key enabler of growth, innovation and efficiency in modern engineering organizations. A communal space where all stakeholders can access the complete ‘digital thread’ of a product really is an investment in ‘tomorrow,’ and the rewards can be significant.

Where today meets tomorrow

At Siemens, we continually strive to enable the future for our customers. In the world of simulation and test, a key part of this is flexible, open and integrated SPDM software with Teamcenter Simulation. The ‘Spring 2022’ release offers a number of new avenues for integration and collaboration.

Let’s get into it!

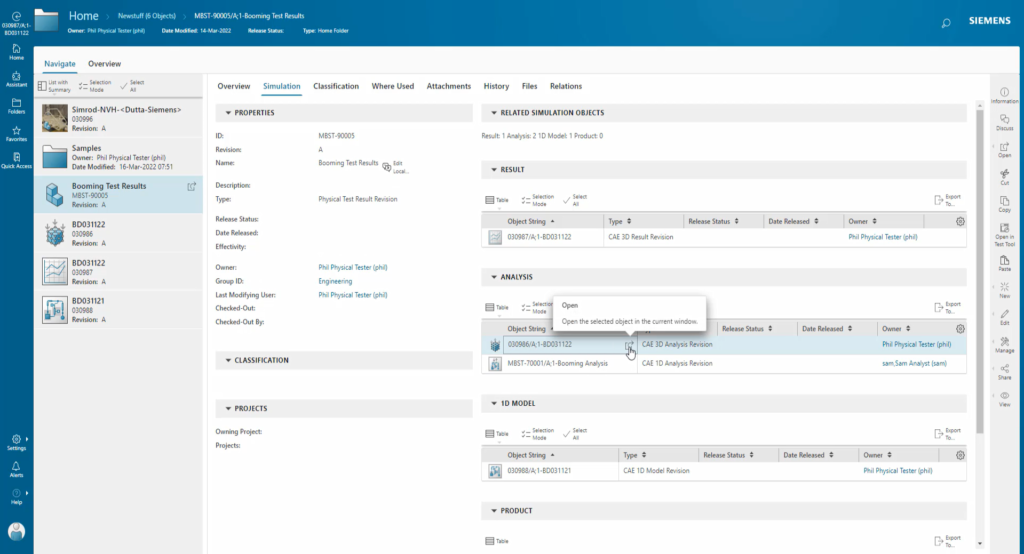

The first announcement is the arrival of physical test data in Teamcenter Simulation. As we will see, this opens many new opportunities, not just to manage physical test data, but also to bring that data into the context of simulation. We will glance over a few important enhancements that further strengthen support for the system simulation domain, and finishing up with a brand-new capability for collaboration in the cloud.

Teamcenter Simulation is now open-access land

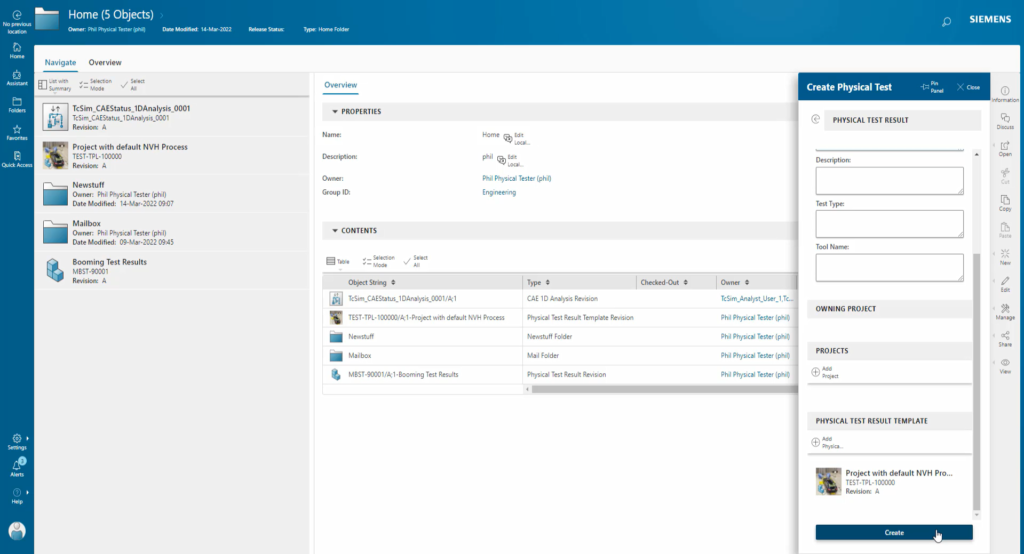

Let’s first take a look at our new capabilities for managing physical test results with Teamcenter Simulation. While the key needs (traceability, consistency, ease of access) for physical test data management are very similar to those for simulation data, there are also significant differences in terms of workflow. Consequently, the first thing to introduce is a dedicated new environment and roles for testing engineers and users.

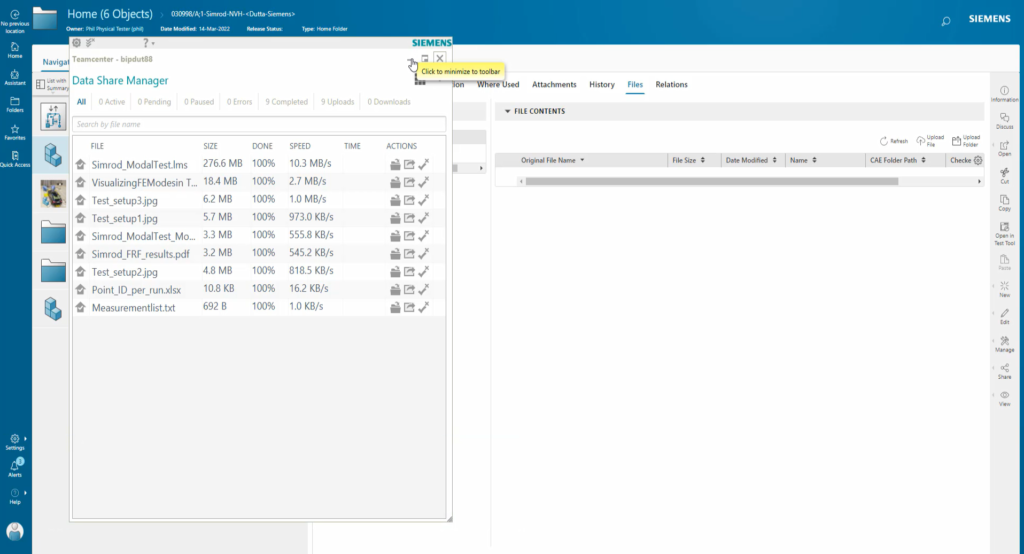

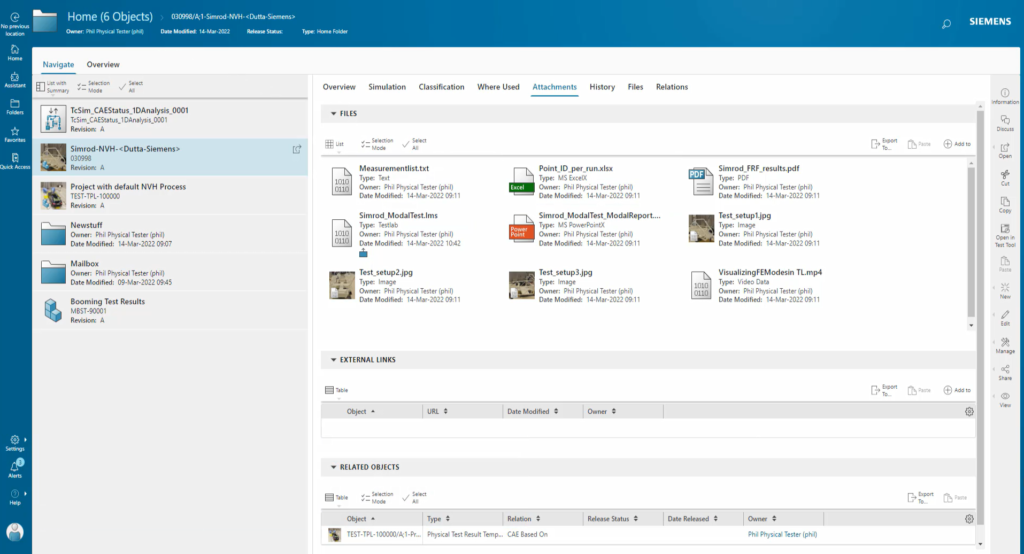

Here you will find the key commands at your fingertips. A streamlined process for bringing physical test data into Teamcenter Simulation minimizes the user’s workload with reusable templates for import. Data processing happens in the background with the Data Share Manager, allowing you to focus on your analysis work while all the heavy lifting is taken care of.

Ready for cross-pollination, or correlation

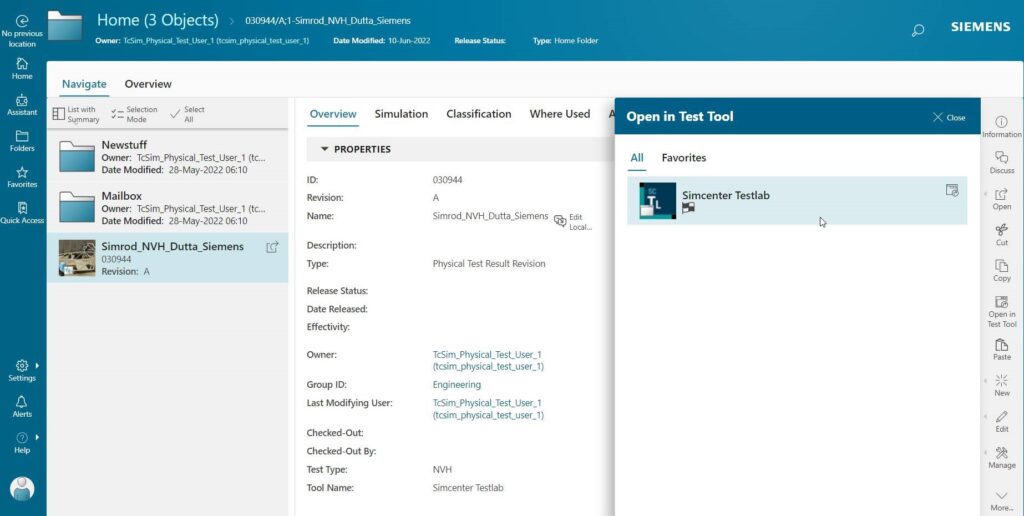

Of course the benefit of incorporating physical test data into an SPDM software platform is not just storage and organization. It is the ability to share and analyze that data that enables you to discover engineering insights. We have made this process easy with a direct connection to Simcenter Testlab.

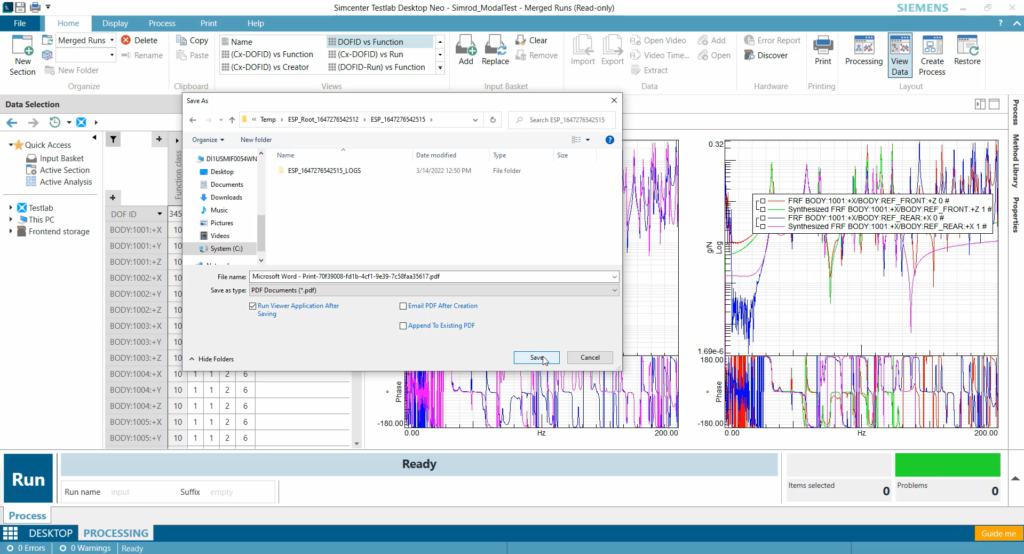

You can now download data and load it into Simcenter Testlab for post-processing with a single click. As with all desktop tools integrated with Teamcenter Simulation, results, images or reports that you create with Simcenter Testlab are automatically retrieved on closing the tool. Not only are they saved but also planted safely in the garden (a.k.a. the Teamcenter database). The same process automatically links all of these files back to the source data to become part of the digital thread of your product.

Now that we have brought physical test and simulation data together, we also open the door to yet more routes for collaboration. In a few simple steps, you can link physical tests to simulations to streamline correlation, model updating or pre-test activities. All of the data is right there and ready for re-use.

What else has happened in the Teamcenter Simulation garden this spring?

Starting with system simulation, there are several new launch options for Simcenter System Architect, including a batch mode option. This, combined with a new ability for Simcenter System Architect to directly access input parameters from Teamcenter Simulation and return output parameters, means that you can easily configure and run additional design variants or load cases directly from inside Teamcenter Simulation.

There are also enhancements to the integration with Simcenter System Simulation Client for Git. The process of publishing system simulation models to Teamcenter Simulation now automatically stores relevant metadata. So you can rely on consistency between the two systems – and you get some back some time in your day for sunbathing, how about that!

More paths to collaboration with Teamcenter Simulation

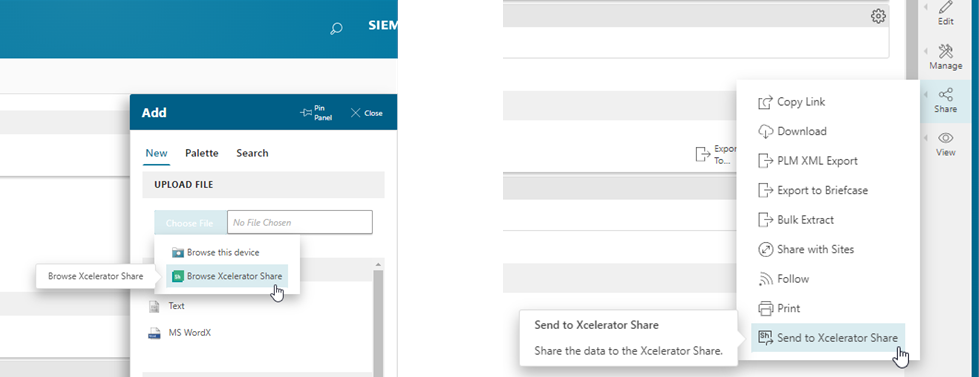

While the benefits of formalized workflows and collaboration using SPDM software are well established, in some cases more ad-hoc means of collaboration is needed to get the job done. This can be especially useful when working with external stakeholders or suppliers, or even as a first step towards a data management system for small organizations.

As seen in the story above, Xcelerator Share is a flexible way to share data from Teamcenter for collaboration beyond your company boundaries. In this release, you can now do the same thing with Teamcenter Simulation to share simulation and test data with stakeholders outside of your SPDM ‘garden’.

Now… time to enjoy the summer sun

Anyone still reading at this point is probably either a SPDM evangelist or just curious to see how thinly I am prepared to stretch the gardening analogy.

For the former – I hope you will be able to take advantage of some of the great new capabilities we have looked at. I’m sure you’ll agree they represent another significant step in up in flexibility and openness of the Teamcenter platform for SPDM, broadening horizons and opening new routes to increase productivity.

If you are just here for the gardening – time to get back to the weeding!

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io