- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

CAM SERVICES

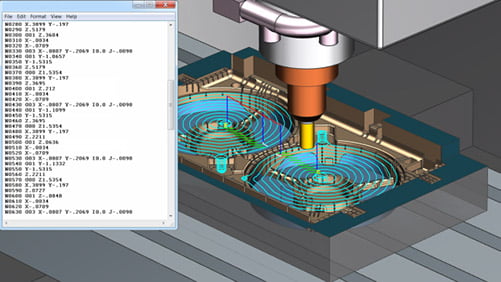

CAM Software – Post Processing – Machine Simulation

CAM SERVICES

Computer-aided manufacturing (CAM) requires a good plan and technology to be effective. Do you have a complete solution for programming CNC machines and robots? Advanced CAM technology, including high-speed machining, feature-based automation, multi-axis milling, and G-code-based simulation, can boost your company throughput. Let the PLM team of veteran manufacturing engineers help you integrate your CAD and CAM to ensure true end-to-end part manufacturing.

PLM VN can help you with below operations

CAM Post Processor Development

You have the expensive machines, now make sure they are performing at maximum efficiency. Let our manufacturing engineers convert your CAM toolpaths into G and M code for your CNC machines – from the simplest 3-axis mill to an intricate 11-axis mill-turn.

We support the following types of machines:

- Multi-Axis Mills, Lathes, Mill-Turn, Wire and Sinker EDM, CMM, Router, Waterjets, Laser, Welder, Plasma, and Grinders.

CAM Simulation Development

Validate your NC Programs on a Virtual Machine Tool. Optimize the value from your machines and eliminate wasteful downtime.

- The simulation will show all the moving components of your machine.

- You can verify your setup and watch your part run on the machine before it hits the shop floor.

- This ensures there are no collisions.

NC Programming

Having trouble getting parts programmed on time. PLM VN can help! Call us for a quote to program your simple or complex parts.

Onsite Coaching/Mentoring

Our Manufacturing Engineers have real-world experience and expertise to…

- teach you about specific manufacturing issues.

- coach you on your manufacturing skills.

- facilitate growth by sharing resources and networks.

- create a safe learning environment for taking risks.

PLM VN mentoring can be done at a PLM VN office, your facility, or via the web.

Template Customization

Do you have a family of parts or a variety of machines, or do you simply want to change your NX operation’s defaults? Get custom CAM templates created so you can accelerate work. Custom templates can be configured for:

- Machines

- CAM Programmers

- Part Families

- User Groups

- Tooling/Materials

Shop Doc Customization

We can help you set up automated documentation for the shop floor operators, such as setup sheets, tool lists, and operation list per job, along with overall cut time and individual operation cut times.

How can we help you?

“PLM VN has always been extremely helpful and quick to help from my many years of experience with you all. Thank you.” – Industrial Machining Services

Subscribe

Get the latest tips, software updates and promos.