Old habits die hard. Although technology has made leaps and bounds in recent years, many manufacturing companies are still using the same processes that were implemented decades ago. Mainstream product lifecycle management systems were designed 20-30 years ago. and they are not capable to support modern business models, organizing business…

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Uncategorized | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

Data Model Evolution For Future PLM Platforms

Data is at the heart of every PLM technology and system. Therefore from a very early stage of PLM development software vendors put significant attention on how to create the best data modeling capabilities for their PLM system and technologies. A few months ago, I published my article where I…

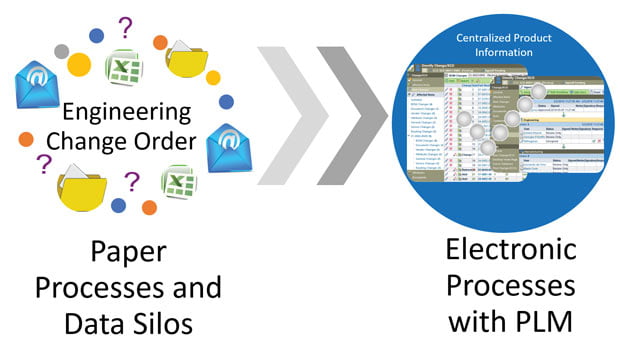

The What and Why of an Engineering Change Order

Explore what an engineering change order is, the stages involved, and the business benefits that come along with it.

How To Turn Manufactured Products in SaaS Services?

Back in the old days of manufacturing, companies were selling products. We used to buy these products (actually we still do). We still can go and buy a car, computer or furniture. Although it is still happening to us, the business environment around these products is fast moving forward. The…

A PDM System that Can Grow to PLM is a Good Start

A product data management (PDM) system enables you to manage all of your product and process-related knowledge in a single secure but accessible system that connects people and applications across your business. With a PDM system in place, product information assets can be coordinated and synchronized, enabling your business to: Improve productivity and reduce cycle

![[Simcenter Solutions] for Energy and Utilities Performance Engineering 8 Oil and Gas Hero Image 640x360 tcm27 38127](https://plmes.io/wp-content/uploads/2020/12/Oil_and_Gas_Hero_Image_640x360_tcm27-38127.jpg)

[Simcenter Solutions] for Energy and Utilities Performance Engineering

▶️ About Simcenter: Engineering departments today must develop smart products that integrate mechanical functions with electronics and controls, utilize new materials and manufacturing methods and deliver new designs within ever shorter design cycles. This requires current engineering practices for product performance verification to evolve into a Digital Twin approach, which enables to follow a more

10 secrets to a stunningly fun CFD simulation

Another Friday afternoon, another chance for a fun CFD simulation! Those tiny little projects we do out of pure curiosity. The ones we sometimes do just because we can. The ones we do because we all like those five minutes of fame when our engineering mates give us their kudos. But most importantly, the ones