- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

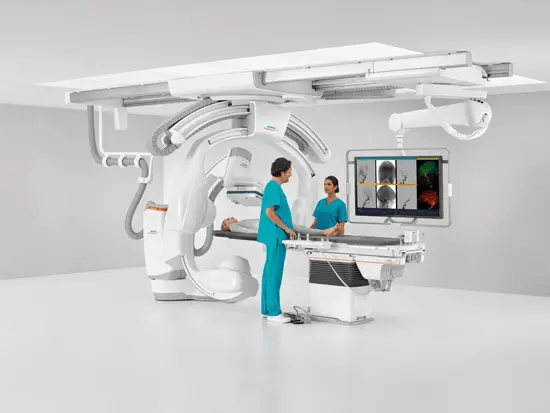

MEDICAL DEVICES

Medical Devices

PLMES PLM Software provides solutions for managing product knowledge across the entire organization. Medical Devices instruments and equipment companies can be confident in our solutions for regulatory compliance, engineering process, and content and document management.

Competition, regulations, costs and organizational complexity increase your risks and require you to be prepared for a wide range of complications. Despite these complications, you not only have to build the right product, you must also build the product right. The best way to get there is to make better, more informed decisions, based on:

- Integrating all cross domain knowledge together in a single, logical location accessible by individuals – no matter where they are in the world or in the organization

- Giving decision makers the ability to make more collaborative decisions in concert with others, while knowing how the decisions they are making impact others throughout the organization, whether it is mechanical design impacting electronics;

- Electronics design impacting software; or the ripple effect of a change throughout the entire system

- Enabling cross-functional knowledge sharing, and giving individuals what they need to make the right decision as quickly as possible

- The best way to stay in control and make better decisions for your development, manufacturing and quality process is a strong PLM solution

Meeting medical Equipment Industry challenges –

Developing a medical device has always been a complex process, or rather a network of complex and inter-related processes. Today’s medical instrument and equipment companies must manage increasingly complex product development processes with the highest efficiency. Meanwhile, the pressure mounts to meet such challenges as:

- Regulatory requirements

- Systems engineering

- Risk management

- Competition

- Increasing costs

PLMES PLM Software’s full set of product lifecycle management solutions enables medical instrument and equipment companies to achieve balanced control, predictable program schedules and costs with competitive capability and performance and performance by taking advantage of:

- Integrated engineering applications with world-class features and functions to enable efficient product and process development, even in a multi-CAD environment

- Document controls and lifecycle traceability, connecting workflows and deliverables from R&D, manufacturing, quality, services and regulatory; reducing risk and enabling re-use for future products

- Predictable design control, connecting schedules and deliverables with actual workflow execution and confirmation of outputs through verification and validation