Công Nghệ Thực Tế Ảo Đang Cách Mạng Hóa Mô Phỏng Và Nguyên Mẫu Công nghệ Thực Tế Ảo (Virtual Reality – VR) và Thực Tế Tăng Cường (Augmented Reality – AR) đang tạo nên cuộc cách mạng trong lĩnh vực mô phỏng và nguyên mẫu, thay đổi hoàn toàn cách mà các kỹ sư

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

3D Printing | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT

Các bạn nghĩ gì về những tiến bộ được thực hiện với AI và công nghệ Digital Twin?

Các bạn nghĩ gì về những tiến bộ được thực hiện với AI và công nghệ Digital Twin? Công nghệ “Digital Twin” là một “bản sao kỹ thuật số” của một đối tượng, quá trình, hoặc hệ thống vật lý. Nó được sử dụng để theo dõi, phân tích và tối ưu hóa hiệu suất

Nhà máy kính số hóa: Đổi mới sản xuất cùng Hệ sinh thái PLM (PLMES) & Siemens!

Nhà máy kính số hóa: Đổi mới sản xuất cùng Hệ sinh thái PLM (PLMES) & Siemens! Thế giới đang thay đổi và sản xuất cũng vậy. Trong bối cảnh thị trường sản phẩm luôn trong trạng thái biến đổi, làm thế nào để bạn luôn nắm bắt được những xu hướng mới và kiểm

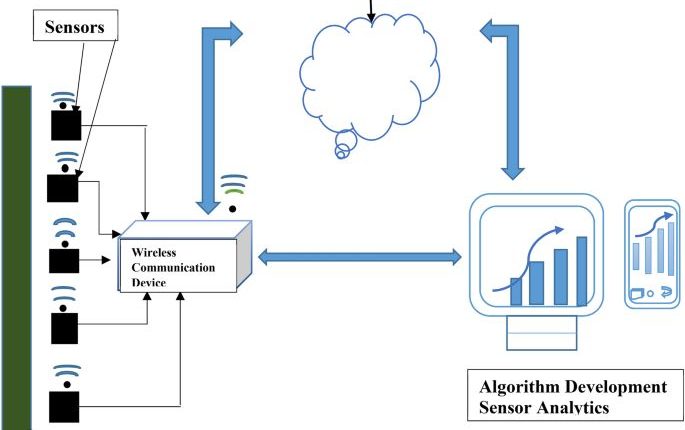

Nâng Cao An Toàn Đường Ống Dầu: Phương Pháp Digital Twin Kết Hợp Dự Báo và Học Máy

Nâng Cao An Toàn Đường Ống Dầu: Phương Pháp Digital Twin Kết Hợp Dự Báo và Học Máy 🛢️ Giới Thiệu Trong ngành công nghiệp dầu khí, đường ống dầu đóng một vai trò quan trọng và rất dễ gặp nguy cơ tai nạn, làm cho việc bảo dưỡng càng trở nên thách thức. Bài

Tìm hiểu từng bước thiết kế quy trình làm việc trong Teamcenter

The Workflow Designer in Teamcenter allows you to create and manage workflows to automate and streamline business processes.

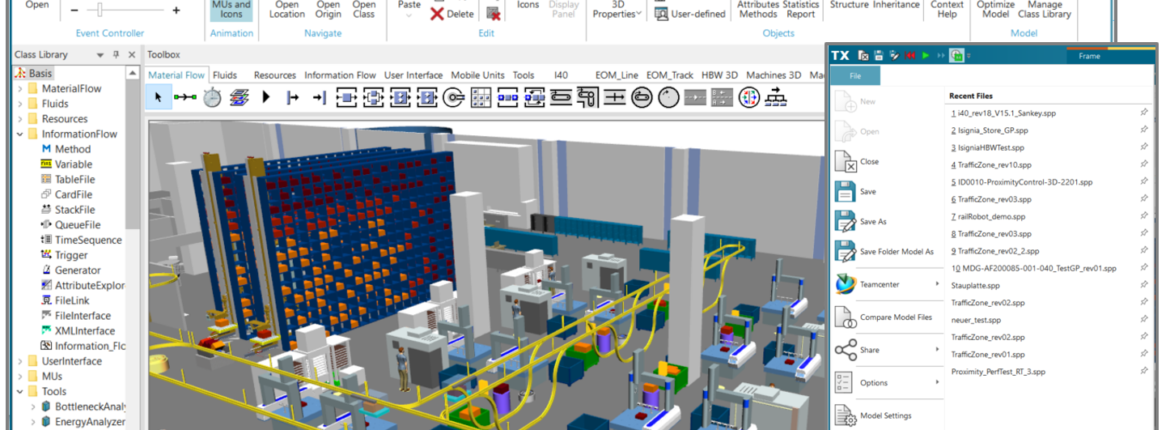

Digital Factory là gì? (phần 1)

Digital Factory là kết quả của một chiến lược chuyển đổi kinh doanh/công nghệ số nhằm cho phép sử dụng dữ liệu từ con người, thiết bị và hệ thống để xác định và ưu tiên các sáng kiến cải tiến liên tục. Ở bản chất, cuộc cách mạng này là lớp quản lý (MOM)

What’s New in Simcenter Mechanical simulation – 2212 Release – Simcenter

Predict mechanical performance of your detailed product designs across multiple physics disciplines. Learn what’s new in the Simcenter Mechanical 2212 release.

How 3D Printing Is Changing The World? – Manufactur3D

3D printing is changing the world as we know it. This fascinating technology allows us to create physical objects from digital designs