Line planning for the medium-sized manufacturer

Medium-sized manufacturing companies must leverage the business impact of investing in digital manufacturing technologies to remain competitive in today’s industrial markets.

—–

This is the first in a series of blogs where we discuss the value of line planning today and the potential benefits that can be realized by medium-sized companies utilizing Digital Manufacturing solutions for this purpose.

—–

Are you a medium-sized manufacturer? If yes, let’s talk about the many challenges that are facing you today. Do any of these apply to you?

Market uncertainties

Increasing cost pressures are causing many manufacturers to evaluate their production strategies and, in many cases, to adjust their production to be more customized to the demand of their customers. This requires a robust understanding of their existing processes and related data to quickly adapt and create new manufacturing processes that match those needs.

Ongoing improvement initiatives

Manufacturers are always in a state of continuous process improvement, and there is always an expectation of realizing new efficiencies to improve overall performance.

Rapidly growing portfolios

As product portfolios and product complexity increase, there is still a need to reduce the time it takes to introduce a new product. To compress this new product introduction (NPI) time, it is necessary to understand how to leverage existing production lines and facility layouts for new and varied products without shifting too much effort into revisiting the layout again and again.

Increasing system complexity

More and more products include more parts, sophisticated assemblies, and different materials, resulting in building production lines that will handle all relevant product variations and complexities.

Cost

There is still a need to be more competitive on cost per product produced for all the above.

Visualization

Presenting results to colleagues, management, and customers requires more than just 2D drawings and some basic visual effects. These days, everybody expects to see a video game level of visualization, to explore all the details in as realistic an environment as possible.

What does this mean for you?

We have just mentioned many different challenges that you know about, and there are more that you may not have considered, but how can you solve them? Some manufacturers address the challenges discussed here with tools such as spreadsheets and SharePoint sites, but we will share how you can achieve much more with Siemens’ advanced tools.

According to a recent IDC study, manufacturing is the area where you will get the most impact for every dollar that you spend as an investment. Meaning, you can solve or at least reduce the challenges with the help of technology in manufacturing.

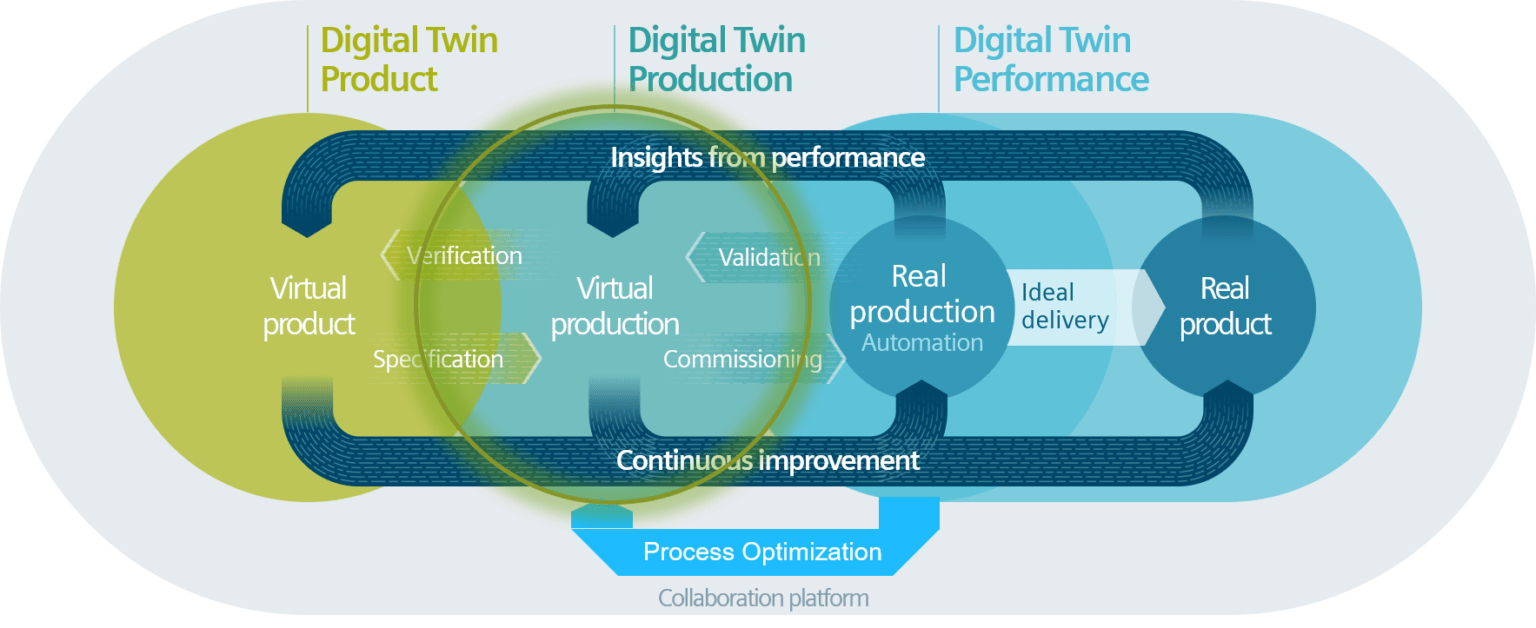

Enter Siemens. We have the right infrastructure for harnessing the technology for your benefit – the digital twin. Here, we introduce the digital twin of production shown at the center top of our diagram below. Circled is virtual production. Virtual production is what you would use the digital twin for – on your way to resolving your current challenges.

The digital twin has long since established itself in industry. It enables the individual process stages to be seamlessly linked. This creates a consistent improvement in efficiency, minimizes failure rates, shortens development cycles, and opens new business opportunities.

Read more about the digital twin here.

Our line planning portfolio offers a selection of digital twin capabilities to address unique challenges you may have, assisting you in starting where it matters most, but offering a growth path as your own business grows – a direct result of where you choose to start with the digital twin.

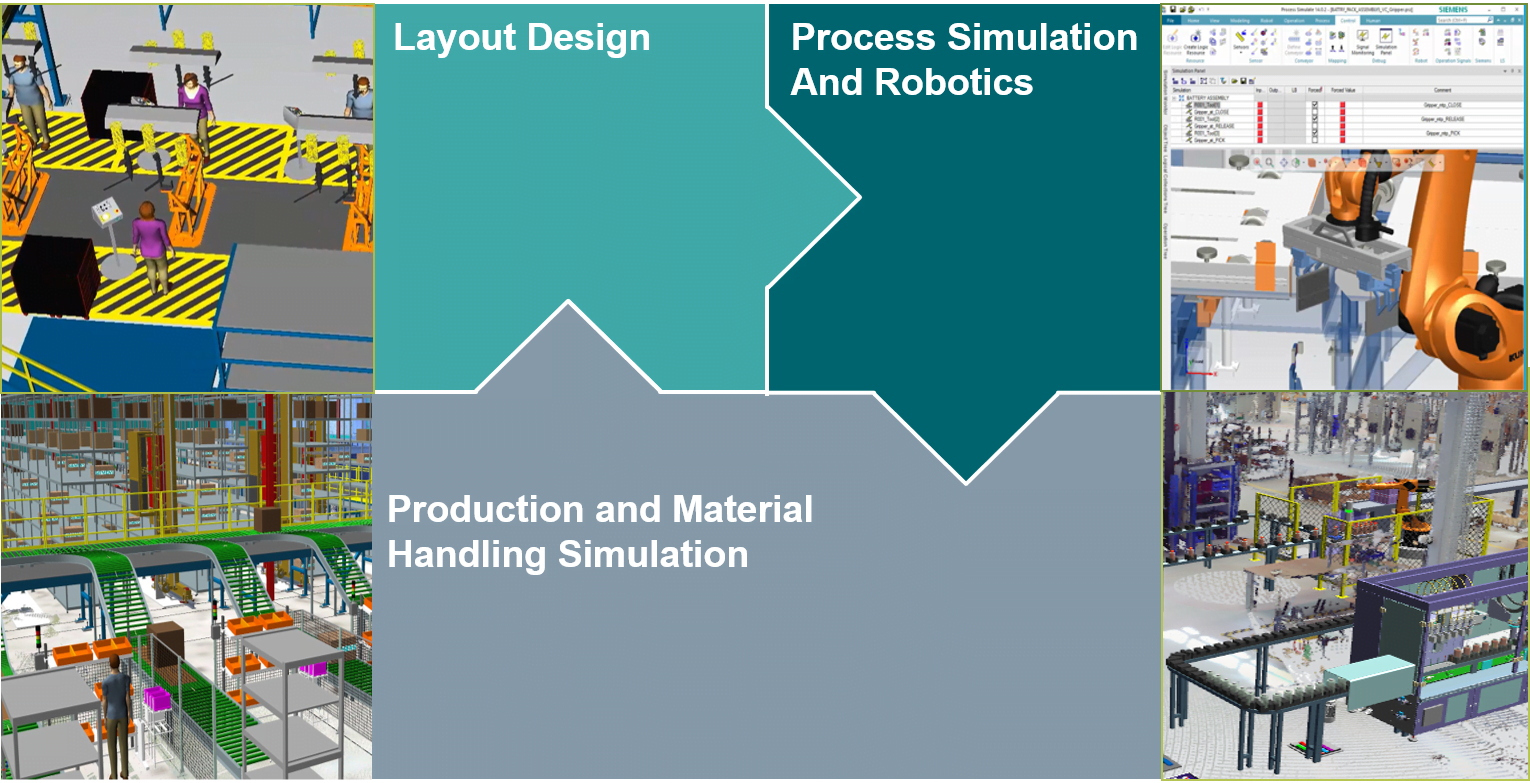

In subsequent posts, we will focus on the different solutions and how they can help. We will cover how to plan your production lines so that they will be flexible, optimized for space and collision-free, without any bottlenecks, and able to adjust to different variations of products in a short period of time.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io