Humble beginnings

Not all early purposes of 3D printing have been a pure novelty. In actual fact, it might have been utilized much greater than you anticipate, underneath the time period of speedy prototyping. These early implementations extra doubtless used a subtractive course earlier than creating a 3-dimensional geometry. Simply as with planar printers at present, a layer is created and stacked in sequence with different layers till a 3rd dimension is shaped from two-dimensional geometries. This grew to become a quick pathway to grasp the bodily dimensions of a product in the course of the design part of growth. Slightly than ready to get a pattern again from manufacturing or a provider, the prototype might be made onsite. However, what could be thought of as ‘actual’ 3D printing would take some extra time.

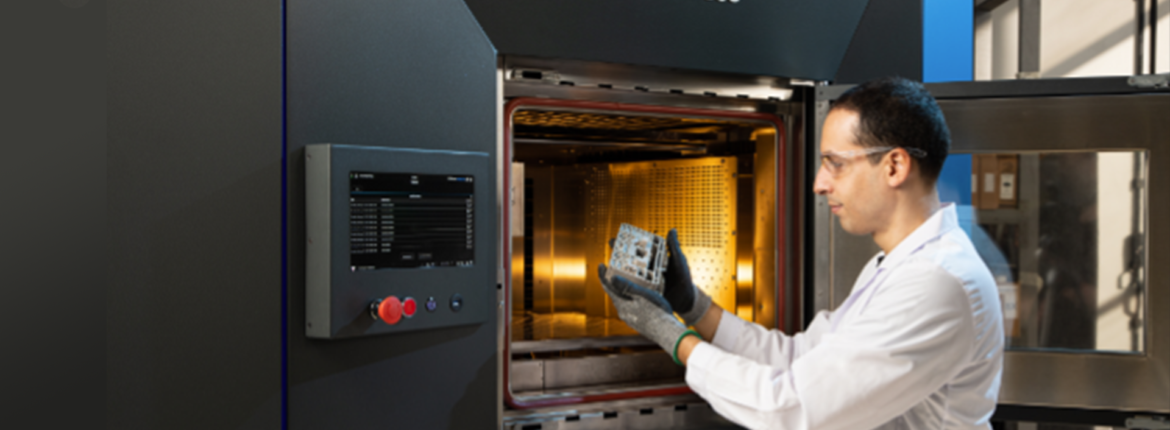

In the present day, you may print useful prototypes and even production-ready elements in a matter of hours relying on the general quantity. Sadly, there are nonetheless some optimizations that should be made to make AM a realistic choice for at present’s merchandise. There’s nonetheless some trial and error to discovering the right half and printing it properly each time. And these prices could make AM tough industrial funding when the main promoting factors are lot sizes of 1 – a misprint will instantly double the fabric and time assets of the venture. However all shouldn’t be misplaced, there’s nonetheless huge funding within the house by means of software programs and {hardware}.

Continued funding

We’ve talked about it earlier and it’ll proceed to enter the dialog when speaking about bettering the AM workflow, however, the Middle for Superior Expertise Collaboration Hub (CATCH) in Charlotte North Carolina is devoted to accelerating the industrialization of AM. This initiative from Siemens is supposed to fill the hole between the work of Oak Ridge Nationwide Laboratory (ORNL) and the Division of Vitality within the Manufacturing Demonstration Facility (MDF) and what’s being adopted in industrial environments at present. Invoice Peter of ORNL put it succinctly that “our DOE-funded analysis is commonly finest leveraged by means of regional and nationwide collaborations like CATCH and the MDF, serving to advance additive manufacturing know-how, drive workforce growth and create an extra environment friendly and de-carbonized manufacturing base.

And for Siemens, the targets are clear in accelerating the adoption of AM. Tim Bell of Siemens Digital Industries might have mentioned it finest, “[t]he advantages of additive manufacturing are clear, from quicker time-to-market to a higher design by means of digital prototypes, to localized manufacturing serving to scale back provide chain constraints.” However, we aren’t the ones that see additives as a significant participant in the way forward for manufacturing.

Extra consideration

On high of the monetary funding within the know-how by means of the Division of Vitality and personal enterprises like Siemens, there’s additionally the funding of consideration on the federal degree in America on accelerating the adoption of additive manufacturing. The US government launched Additive Manufacturing Forward in early Could to dive into the potential advantages of an AM-based manufacturing sector in America. Along with the useful enhancements enabled by AM applied sciences, there are macro-economic causes for the US to spend money on advancing know-how.

First is the infrastructure benefit of additives in rebuilding the nationwide manufacturing sector – it doesn’t require enormous funding for a number of machines sorts to create a variable product set. This permits producers to turn out to be a provider for a larger variety of companies. This progress is being accelerated by means of partnerships with massive OEMs already investing in AM applied sciences. Pushing to construct a worth chain with AM capabilities will diversify the variety of suppliers able to print regionally – boosting native growth. And as extra enterprises are engaged in the know-how in parallel, it’s going to turn out to be built into the conventional operations of the manufacturing sector more reasonably than a distinct segment use case. AM is not going to take over capability from different strategies, a minimum of not quickly, however, the supply instances of additive components over a solid or cast one are invaluable, making complicated applications extra worthwhile.

Nonetheless a thriller

Most of the questions of AM are but to be answered, and for a lot of evidence, we’re solely discovering extra inquiries to ask. However, that additionally means we’re studying increasingly more concerning the know-how and its revolutionary methodology to design and manufacture. We’re beginning to ask for suitable inquiries to make AM a realistic alternative for what you are promoting and trading. Even the most important OEMs try to determine the very best use instances for their industries. I’m excited to see what questions are requested subsequent in evolving the additive manufacturing course. For extra data on the present wants of AM growth, the NYTimes has an important overview from an extra generalized enterprise perspective.

Siemens Digital Industries Software program is driving transformation to allow a digital enterprise the place engineering, manufacturing, and electronics design meet tomorrow. Xcelerator, the great and built-in portfolio of software programs and companies from Siemens Digital Industries Software program, helps firms of all sizes create and leverage a complete digital twin that gives organizations new insights, alternatives, and ranges of automation to drive innovation.