Simcenter STAR-CCM+ 2021.1 released! What’s new?

As the world evolves, engineering needs to adapt faster than ever before. To stay competitive, companies need to turn the explosion of the complexity of today’s products into a competitive advantage. Engineers need to turn technical problems into opportunities. It would help if you designed ships and airplanes that are stronger yet lighter, cars and trains that are faster yet more efficient, turbomachines and powertrains that are more powerful yet greener.

You need to deliver fluid dynamics solutions that are superior, yet cheaper. And you need to deliver those flow solutions quicker, yet with more accuracy.

With Simcenter STAR-CCM+ 2021.1, Siemens Digital Industries Software introduces a host of new features to help you design better products faster and with greater confidence.

Join our Virtual Launch Event of Simcenter STAR-CCM+ 2021.1 on March 9, Live on LinkedIn

Increased insight into turbomachine performance

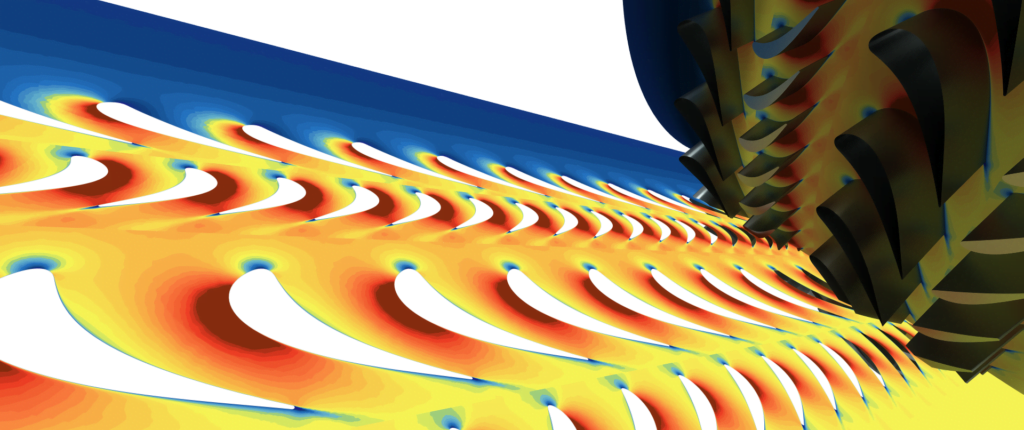

3D analysis of a turbomachine offers deep insight into local flow features to assess its performance. With Average Solution Visualization, you can now circumferentially average the flow solution better to visualize macroscopic features such as hub or shroud separation so that you can readily identify issues in the flow path and ensure the intended performance is achieved.

Another important data analysis tool for better engineering decisions across blade designs is the blade-to-blade view. With Section Flattening, you can now project a complex 3D blade-to-blade solution to a flattened 2D view. This helps you to understand performance, visualize flow behavior, and ensures consistent comparisons between designs.

Learn more about all the recent advancements in Simcenter STAR-CCM+ for gas turbine CFD

A faster approach to characterizing compressor performance

When characterizing compressor performance, it was often necessary to change the outlet boundary condition type when the operating point moves from choke to surge. The Corrected Mass Flow Outlet BC is a single boundary condition that can now accurately predict all points along the compressor Speedline, saving time and resulting in a more uniform resolution of points.

Learn more about all the recent advancements in Simcenter STAR-CCM+ for gas turbine CFD

Open simulation files without a license for increased productivity

Design engineers need to ensure consistency in their simulation set-up across operating points and design variants. In this release, you can open simulation files in read-only mode without consuming a license, giving you a much greater ability to check your set-up, make comparisons and leverage your best practices across many simulations.

Find out more about the benefits of the read-only mode for simulation files.

Quickly predict the performance of thousands of design variants.

Tolerances can make or break manufacturing processes and need to be considered early in the design process. With Surrogate Models in Design Manager, you can predict the performance of thousands of variants either locally around your design of interest to analyze the probability of failure or globally across the design space to quickly create a database of performance results that your simulation team can leverage.

Learn how to leverage the power of surrogate models for faster engineering insights with confidence

Reduce setup time for electromagnetic simulations

Electromagnetic simulations require the specification of an electric circuit, which can be time-consuming. With the new Electric Circuit Editor, you can readily sketch sophisticated circuits with an easy-to-use and intuitive graphical interface, enhancing the Circuit Model’s usability and saving time. This tool is beneficial for all applications with circuits, including electric machines, circuit breakers, and batteries.

Find out more about the latest advancements on EMAG simulations in Simcenter STAR-CCM+.

Design higher power density electric machines

In this release, we continue to expand the application coverage for electric machines to introduce a new vector method to specify the current direction when using the Finite Element Excitation Coil Model. This approach does not require any boundary, greatly improving the usability of the Excitation Coil Model and enabling the simulation of closed coils such as those found in axial flux machines.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io