Receding Horizon Planner & Plant Simulation optimally assigns tasks to resources in real-time, considering system constraints.

By Matthias Heinicke

A powerful combination for real-time optimization

Lecture at the 2023 Plant Simulation User Conference by Karl Ludwig Fetzer, Ph.D., Siemens Technology

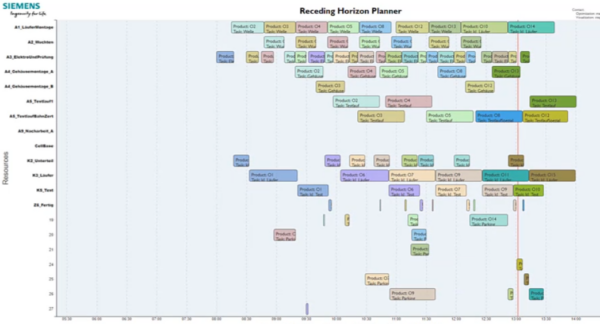

The Receding Horizon Planner (RHP) application optimally assigns tasks to resources in real-time, considering system constraints and interruptions, leading to improved task allocation efficiency. In his presentation, Dr. Karl Ludwig Fetzer from Siemens Technology discusses the benefits of the Receding Horizon Planner application in conjunction with Tecnomatix Plant Simulation software. The presentation highlights the real-time optimization capabilities of RHP, focusing on task assignment, resource allocation and production scheduling while considering system constraints and interruptions.

Siemens Technology, the central research and development organization of Siemens AG, boasts a global team of researchers based in Europe, North America and Asia. Their expertise spans various domains, including automation, simulation, artificial intelligence, sustainability and cybersecurity. These researchers collaborate to address technical challenges across all Siemens businesses, such as Digital Industries, Mobility and Smart Infrastructure.

Receding Horizon Planner

The RHP application, a state-of-the-art optimization tool, employs a rolling optimization approach to intelligently allocate tasks to resources. By dynamically adapting to system interruptions and respecting predefined constraints, the RHP ensures optimal task assignments in real-time. This capability proves invaluable in production scheduling, enabling companies to streamline their operations and maximize efficiency.

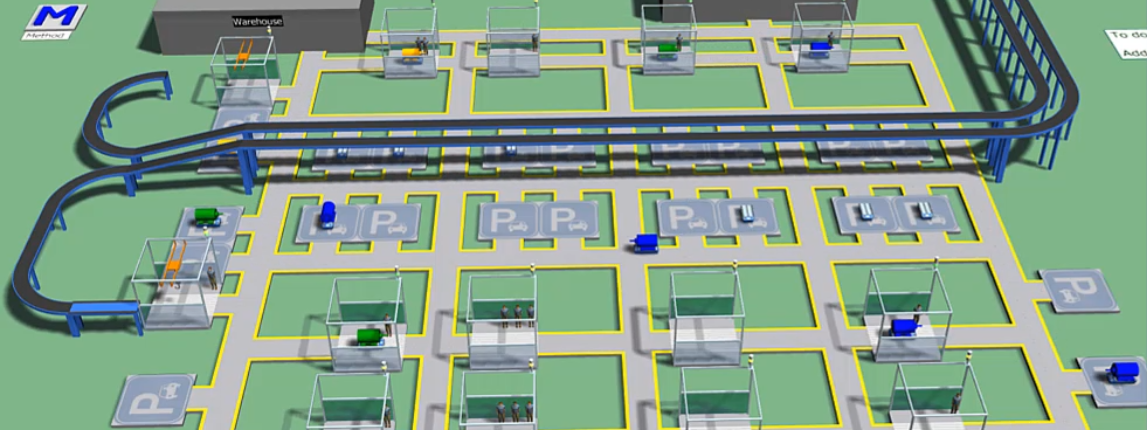

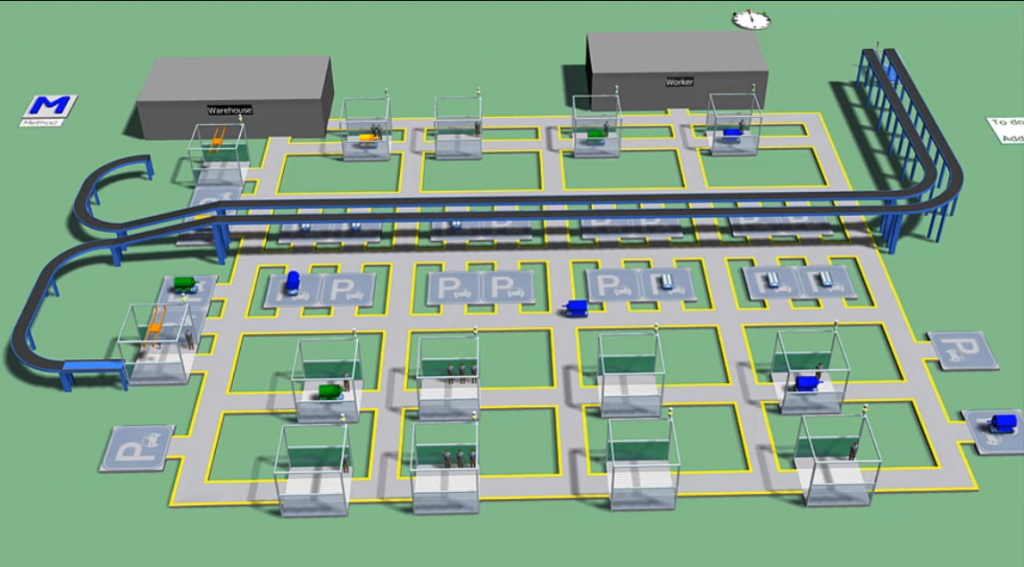

The seamless integration of the RHP application with Tecnomatix Plant Simulation software, a powerful solution for modeling and analyzing manufacturing processes, offers a comprehensive approach to optimizing production systems. It allows businesses to simulate different scenarios, analyze resource allocation, identify bottlenecks and make informed decisions to enhance productivity and reduce costs.

The presentation

Dr. Fetzer’s presentation demonstrates real-world use cases where the RHP application and Plant Simulation software integration deliver remarkable results. By leveraging the strengths of both technologies, companies can achieve optimized production schedules, minimize downtime, improve resource utilization and ultimately boost overall operational performance.

Siemens Technology’s commitment to research and development underscores their dedication to advancing cutting-edge solutions that address the evolving needs of industries worldwide. Through their expertise and innovative tools like the RHP application and Plant Simulation software, Siemens Technology continues to drive the digital transformation of manufacturing processes, empowering businesses to thrive in today’s competitive landscape.

As the industry continues to embrace real-time optimization and digital simulation, the combination of the Receding Horizon Planner application and Plant Simulation software emerges as a powerful solution. This integration promises to revolutionize production scheduling, enhance resource management and elevate operational efficiency, providing companies with a competitive edge in an increasingly demanding market.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io