How an integrated MES can help manufacturers recover from COVID

Some economists have characterized the Coronavirus pandemic as potentially the biggest macroeconomic shock the world has experienced in a century. Amid these challenging times and trends, investing in digital technologies is a good idea for medical device companies. This technology, such as an integrated manufacturing execution system (MES) has become indispensable to medical manufacturing success as companies recover from COVID-19.

Digital technology is the vaccine for manufacturing during COVID-19

In a study done by the Kalinga Institute of Industrial Technology (KIIT) in India, there are three pillars of digital technology that have significantly influenced manufacturing under COVID-19 constraints. These pillars are artificial intelligence (AI), the Internet of Things (IoT) and big data analytics. And at the heart of the digital enterprise, the integrated manufacturing execution system can be used to leverage these pillars for stronger manufacturing progress. An MES may be the most important technology enabler in accelerating the medical device industry’s pandemic recovery.

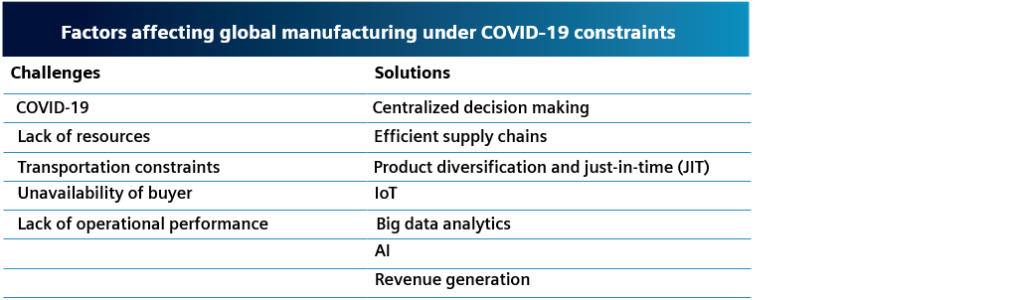

Factors affecting global manufacturing during the pandemic

The KIIT research team conducted extensive literature reviews and came to identify 12 key factors influencing the status of global manufacturing during the pandemic. Each factor was grouped as a challenge or a solution. Using analytical techniques, the team then analyzed how each factor influenced or was influenced by changes in the other factors to determine their driving and dependence power.

The roles of integrated MES in the pandemic recovery

Many manufacturers currently have digital tools integrated with their processes. However, not all manufacturers are fully benefitting from these tools. Now is the time for medical device manufacturers to progress toward a holistic approach known as smart manufacturing. This approach leverages digital design and engineering capabilities that are interconnected with the production environment.

An integrated MES can orchestrate and optimize the production of a finished product based on design, engineering and process data. In the medical device industry, an MES enables teams to prevent errors in the manufacturing process and provides paperless manufacturing.

Learn more about the three pillars of digital technology and how they integrate with an MES here.

To learn more about the medical device and pharmaceutical industry, check out the blog network here.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io