Food and beverage manufacturers are facing complex issues. With the ever-increasing demand for quality and traceability, combined with accelerating global concerns of the effects of food production on the environment, and the need to keep up with the international spread of changing laws and regulat

Food and beverage manufacturers are facing complex issues. With the ever-increasing demand for quality and traceability, combined with accelerating global concerns of the effects of food production on the environment, and the need to keep up with the international spread of changing laws and regulations, businesses are needing to review their operational processes.

Not having oversight of all your operations is a great risk.

As I say, there’s no secrets in the internet age – information can be spread so quickly and often shared through social media, health scares and product recalls can be very damaging.

With companies facing the challenges of lack of traceability, growing regulations, unnecessary wastage, and maintaining competitive advantage, the need for an end-to-end view of the manufacturing process has become the essential.

If you run a food and beverage manufacturing plant, it is easy to lose track of your industry’s latest technological trends that provide that traceability, regulatory compliance monitoring and wastage management. This is especially true if you‘ve not implemented or upgraded your manufacturing operations and execution system (MES/MOM) yet.

Committing to a MES/MOM implementation initiative is no small endeavor. But making the move now can benefit your organization significantly over the long run.

A MES/MOM customized to your unique food and beverage business requirements is a wise first step toward updating your operations and propelling your brand well into the future.

However integrating a MES/MOM solution into your current factories isn’t one to take lightly. It’s a “full-on” People Change, Process Improvement & Tech Solution that of course comes at a cost, industry compliance consideration exercise. The overall time and investment required to deliver a measurable ROI and business case needs evaluating.

1st up is developing a clear understanding of your business objectives and determining exactly what you want to get out of your MES/MOM new solution. You have to feel confident that adopting a MES will help you meet your long-term revenue objectives while providing a quick return on investment.

Today’s challenges for Food & Beverage Manufacturing

Below are some of the challenges facing today’s food and beverage manufacturers:

Changing customer demands

Consumers are armed with information and have higher expectations and needs when it comes to what they eat and drink. For instance, many are becoming more nutritionally aware, with a desire for naturally-sourced ingredients, environmentally friendly packaging and humane sources of farming.

This variability can put significant additional demands on supply chains, and food and beverage manufacturers are charged to handle these challenges while dealing with razor-thin margins.

Changing customer demands

Consumers are armed with information and have higher expectations and needs when it comes to what they eat and drink. For instance, many are becoming more nutritionally aware, with a desire for naturally-sourced ingredients, environmentally friendly packaging and humane sources of farming. This variability can put significant additional demands on supply chains, and food and beverage manufacturers are charged to handle these challenges while dealing with razor-thin margins.

Consumer differentiation

Innovative and growing economies have led to the development of many new food and beverage manufacturers, as well as a multitude of products across different categories. This choice should be good for the consumer, but you may find your organization overwhelmed. It’s the job of established and new manufacturers alike to differentiate themselves from the competition and win traction with consumers.

Cost Margins can be wafer thin.

Costs come in many different forms, from material to labor costs, from packaging to shipping expenses. However, a large proportion of the material costs come from sustainability, such as energy and water costs for example. Reducing cost pressures is directly related to increasing productivity. As an example, if you can increase yields, this reduces the waste produced such as scrap and rework.

Regulatory and compliance

Product safety regulations are complex, vary across countries, and change frequently—almost always becoming stricter. This means that when your food and beverage business expands into different countries, compliance burdens will grow, as well as the likelihood and complexity of a product recall. Legislation gives government agencies more power to intervene with your food and beverage manufacturing operations.

Food traceability and recall management

Food and Beverage needs the ability to trace products as they pass through the long & complex supply chain. Traceability allows businesses to verify the history and location of a product through documented, recorded verification.

The above challenges show the need for food and beverage manufacturers to modernize their operations. By creating the right infrastructure within their businesses, they can gain competitive advantage, improve traceability, reduce wastage and be confident in meeting all regulations globally.

4 Ways to Manage Complex Processes During Food and Beverage Production

Food & Beverage manufacturers have unique challenges. The system that runs food or beverage production becomes critical in ensuring quality, control, operational efficiency—and managing complexity.

To effectively manage complexity while maintaining profitability, you want to look for a system that includes:

Food Safety

Running a food or beverage production requires a complex choreography of scheduling, raw material inventory, batch processing, yield analysis, and production controls, all the while managing and mitigating risks via stringent and timely quality procedures carried out throughout the process.

With an ever-increasing focus on food safety such as the Food Safety Modernization Act (FSMA), those risks bring potentially high costs of failure such as recalls, decreased profits, loss of customers, and potential litigation.

Quality Compliance

- Built-in batch processing controls can reduce the risk of quality failures by forcing operators to perform steps in the proper order using the proper tools and methodologies.

- Checklists for machine setups, clean downs and temperature checks are all validated and recorded at the appropriate point within the process.

- Quality compliance comes from rigorous application of checks and procedures and are no longer just paper documents tucked away in a cabinet. All of these checks need to be recorded and readily available for review by both customers and regulatory body audits.

Traceablility

Inventory Management requires extensive use of lot management and date code processing capabilities that track every lot of every ingredient throughout the production process to ensure ingredient freshness and customer satisfaction.

Rigorous tracking from receipt of raw materials throughout production to shipping of finished goods creates traceability records that can be accessed in moments in the case of a mock or actual recall situation.

You don’t need to spend hours or days leafing through paper documents when you need to answer a question—simply provide this information within seconds with comprehensive traceability reporting.

Batch Scheduling

If you’re producing a variety of products, scheduling tools help to optimize production by considering any number of constraints that can include production run times, machine capacity, labor availability, allergens, colors, packaging etc.

This kind of capability helps to ensure that costs are kept to a minimum by reducing the number of changeovers and clean-downs required between products—bringing significant savings on a day-to-day basis while also offering opportunities for increased production volumes with current levels of resources.

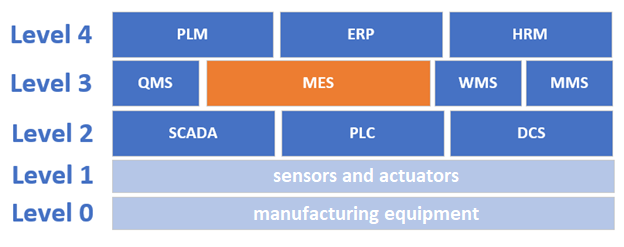

So, what is a Manufacturing Execution System (MES)?

In this age of digital information continuity and seamless connectivity across your organization, I’d typically extol the virtues of the entire Manufacturing Operations Management solution, but for the purpose of immediately impacting your shop floor, let’s keep the focus on the simpler MES

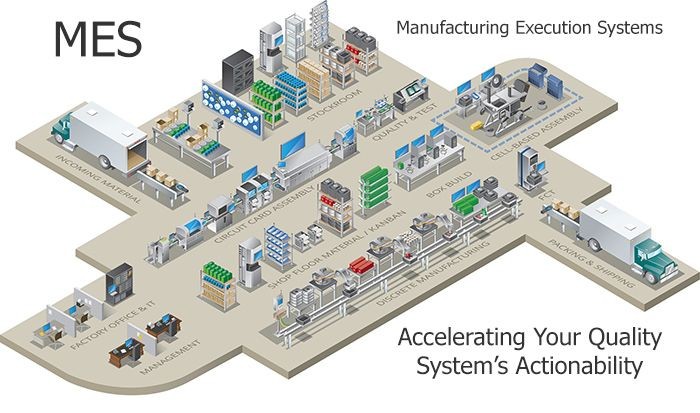

An effective MES solution tracks and aggregates valuable data from your shop floor in real-time, allowing you to monitor various key metrics like production flow rates and operator efficiency.

An MES traces and analyzes each stage of your production to enhance data-driven decision-making and improve general productivity at your plant.

MES is a collection of production information across the entire production line manufacturing processes and provides timely production information, to avoid single-instance production bottleneck.

The MES approach is from a user perspective and to provide real-time information for use on the production lines:

- What information system does the operator need during the production process?

- What information system does the equipment maintenance engineer need during the production process?

- What kind of information system does the process engineer / head of manufacturing / factory manager need during the production process?

- The purpose, category, and role of the information system of the automated process?

The MES is required to provide the users on the production lines detailed analysis and processing data and moreover, the scheduling and overall management information. This then provides production management sufficient data for iteration, thereby providing continuous production management information for the entire plant.

How will an MES benefit your food & beverage manufacturing?

Most of the essential activities take place on the shop floor. However, food and beverage manufacturing is largely dominated with manual procedures and outdated equipment remain unnecessarily exposed to human operator errors and technology malfunctions/downtime.

A production plant that once functioned as a well-oiled machine just a decade ago can easily today find itself struggling to remain competitive in today’s technology-driven marketplace.

To keep pace with the competition, food and beverage production facilities necessitate automated industrial solutions that help their employees gain more efficiency. Well-engineered MES software benefits manufacturing plants of all sizes to operate more smoothly.

Automated execution systems improve decision-making by providing businesses with access to valuable live-time data that hastens reaction times while simplifying your long-term strategic planning.

The right MES solution provides a competitive edge against your large competitors and sets the company on a path of robust and longstanding growth. An MES solution helps your organization:

- Optimize plant floor space utilization

- Follow routine equipment maintenance schedules

- Enhance their existing systems through integration

- Increase productivity and improve visibility

- Find easy access to valuable business data and analytics

- Eliminate components and processes that don’t add value

- Improve customer satisfaction levels

The food and beverage industry is complex, and no two operations are alike. Today’s food production industry faces a multitude of challenges, from supply chain disruptions to labor shortages.

A reliable MES solution addresses most of the common issues food and beverage manufacturers face, but it can also resolve complex and inherent design issues in your plant. Here are a few ways an MES helps you regain control of your production:

Reduced costs

As the cost of raw processing materials escalates, food and beverage manufacturing organizations continue to fight labor shortages, high energy and distribution costs. These expenses add up quickly.

But an MES solution will immediately grant you more insight into your operation by giving you access to data that lets you analyze your plant’s performance in live-time. Comparing production costs in relation to your targets, making accurate predictions, and driving profitability are simplified with an MES.

Easier compliance and quality control

Food safety in the food and beverage manufacturing sector is paramount. Even a minor mistake could cost you considerably. Industrial Platforms and Automation solutions like MES/MOM software gives you significant advantages over traditional methods.

The technology provides more control over your processes to improve product consistency and reduce materials waste.

An MES ensures long-term viability

Implementing new technology to your food and beverage organization isn’t easy, but it does not have to be overly complicated either.

The longer you put off your plans to introduce an MES, the more difficult it becomes to remain competitive in the future.

Manufacturing execution system software increases your margins by ensuring more consistent products and helping you reduce costs through various efficiency gains. The access to real-time operational data means you can start reliably measuring your return on investment and forecasting future revenue.

How does a MES work?

A MES interfaces with multiple areas of your food ad beverage production business. These systems are the most mission critical solutions for handling order execution, resource scheduling, and production analysis.

A Leading MES/MOM includes the following functions:

- Data collection

- Resource management

- Inventory tracking

- Maintenance management

- Quality control

- Performance analysis

After implementing an MES/MOM, warehouse owners and managers reduce material waste and increase production uptime. MES solutions also help optimize warehouse space by keeping inventory low through unique features like finite and visual scheduling along with queue compression.

Warehouse manufacturing execution systems benefit operations of all sizes, particularly those in need of quality control and production enhancements.

Source: Andrew Sparrow

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io