Effectively manage quality control processes

A perfectly planned product requires well-managed production and supply processes to achieve the desired quality. This is an important statement to consider, especially today, where domains are removing their boundaries, and the interaction between them is stronger than ever.

Quality management involves the planning, organization, and supervision of all quality assurance activities. Manufacturers have come to understand that quality must be integrated throughout the enterprise. So, the Quality Control department can no longer play a separate role. The Quality Control function is a supporting role to the manufacturing floor. Still, it has also become part of a bigger picture to ensure consistency, traceability of quality measurements and deviations.

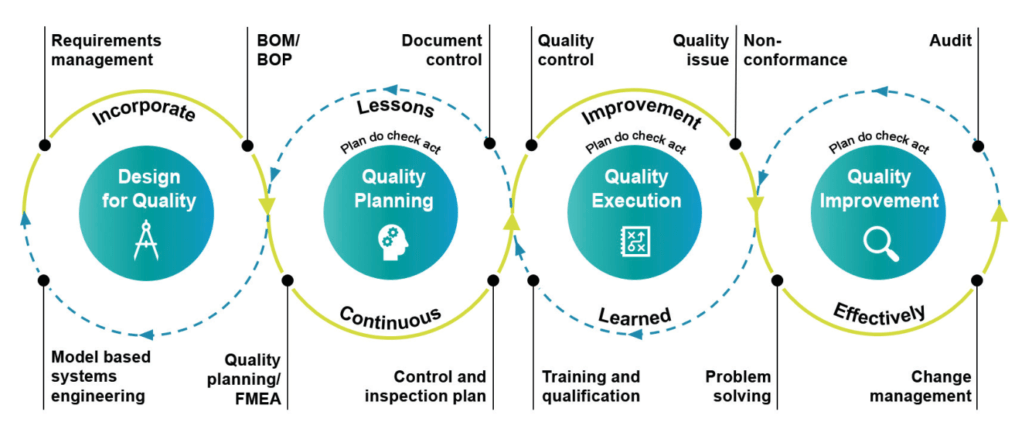

Considering the holistic picture below, it is important to start from the Design stage with Quality insights.

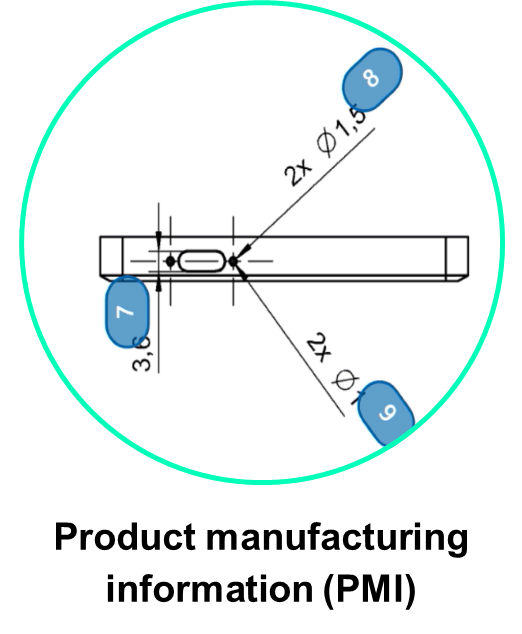

Quality requirements are captured in the 2D drawings or 3D model; they can be used, for example, to create an aggregate tolerance analysis. The quality information, in the form of PMIs – product manufacturing information – is relevant in downstream processes.

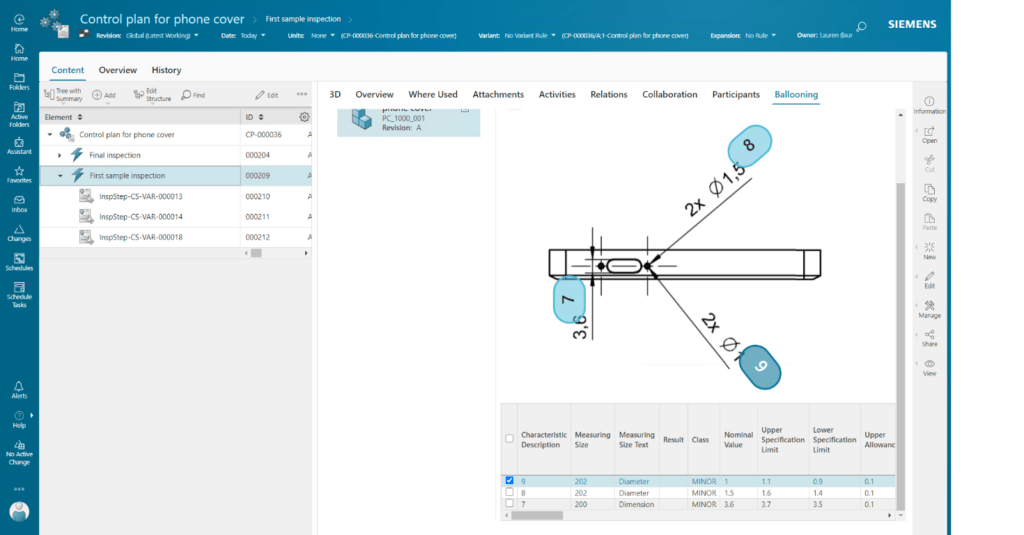

With Quality Planning, the project quality is monitored. The FMEA (Failure mode and effects analysis) provides the toolset to identify and mitigate risks in the virtual product and process structures. Residual risks are managed through the Control Plan with inspection plans for critical characteristics to be checked on the real product.

As described, the technical information is available directly on the 3D model or the 2D drawing with their PMIs. By leveraging on PMI’s, quality and manufacturing engineers can access this enhanced information in a way that provides the required information for production and quality inspection that the design characteristics alone cannot provide.

Detect tolerance variances, identify root causes, and correct defects

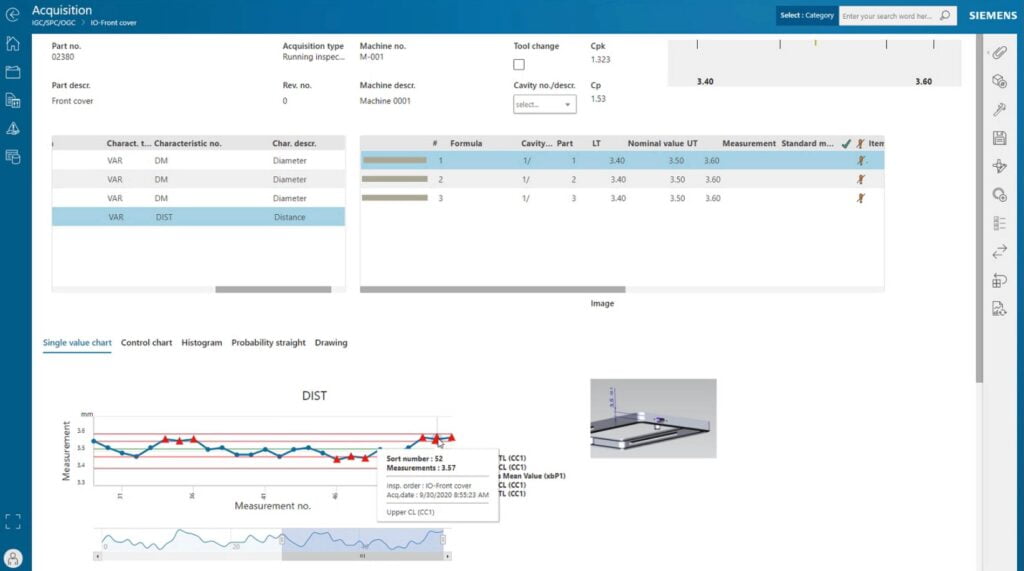

Quality data can be captured in several systems to execute defined inspections. Thus, the statistical process control (SPC) methodology helps manufacturers measure and control quality. Leveraging SPC, it is possible to detect tolerance variances, identify deviations in real-time.

The Quality Control engineer can create control charts to graphically plot and distinguish between coincidental and systemic quality factors that can influence production. By evaluating the control charts, the quality specialist determines whether instability problems can be solved on the manufacturing shop floor or if measures need to be escalated for management review. If a deviation is detected, the Quality engineer needs to initiate a systematic problem-solving process to solve the issue immediately.

Fig. Capture all data and deviations from quality execution system

Fig. Capture all data and deviations from quality execution systemLeveraging effective quality planning, SPC tools, and related evaluation systems, manufactures can reduce the margin of error and dramatically improve the quality control process while lowering the risks and costs associated with defective products.

Discover more about Quality Planning, Quality Assurance, and Quality Control today.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io