Lifecycle Insights’ 2021 Computer-Aided Design (CAD) Productivity Study demonstrates executives want to see increased productivity from their mechanical design teams. One way to reach that objective is to integrate CAD solutions with product data management (PDM) or product lifecycle management (PLM) platforms. That’s why many CAD solution providers now offer more functionality to align these systems. Manufacturers benefit when they upgrade to the latest release of their CAD solutions to leverage these integration features.

Executives Are Seeking Productivity Gains

Today’s manufacturers are looking at ways to increase productivity. To better understand how new releases of CAD solutions influence engineer productivity, Lifecycle Insights conducted the 2021 CAD Productivity Study.

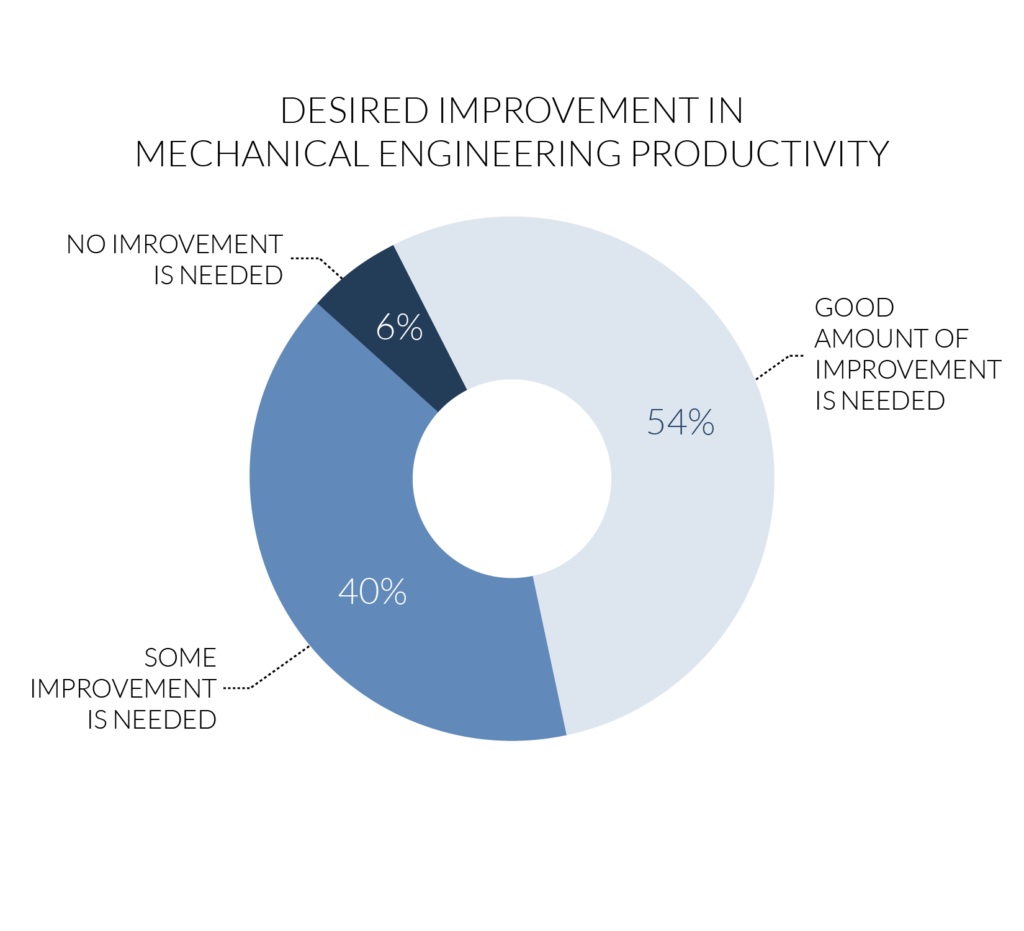

In this survey, we asked respondents about executives’ attitudes towards productivity, particularly with regard to mechanical design teams. More than half of the study participants (54%) stated there was a need for significant improvement in productivity, while another 40% cited the need for some improvement in productivity. Only 6% of executives were satisfied with the current productivity of their mechanical engineering or mechanical design teams.

Where might executives find the productivity boosts they are seeking? Their CAD solutions offer several features that can help. We’ll discuss the importance of CAD integration with PDM/PLM solutions in relation to productivity gains for mechanical design teams.

Growing Complexity of Products: Its Implication of CAD and PLM

CAD solution providers are adding new features and functionality aimed at boosting productivity for design teams. Yet, with every new release, managing CAD data becomes more and more complex. Respondents in Lifecycle Insights’ 2021 CAD Productivity Study echoed this statement. In fact, more than two-thirds of survey participants noted that managing CAD data has become increasingly complex.

It’s no wonder. Modern mechanical products was always bound to increase complexity. Every year, the products that companies develop are getting more and more sophisticated. As a result, companies adopt PDM and PLM solutions to support improvements to the product development process. Lifecycle Insights’ ROI of Digital Transformation (DX) study earlier showed that most progressive organizations have had PLM in place for more than a year.

CAD solution providers have noticed these concerns. They are responding by adding more PDM/PLM integration capabilities within their CAD solutions. These new capabilities can help engineers better manage CAD data and access the latest designs. Since designing modern products is a team effort, most manufacturers have many engineers working on different aspects of a single design. It’s vital that the entire team can not only access the latest design but keep up with any changes. Integrating CAD with a PDM/PLM solution enables engineers to achieve this.

As a result, we used questions in the CAD Productivity Study to ask participants about CAD and PDM/PLM integration. The research participants stated that integrating the product development process with their PDM/PLM solutions is more challenging because of the complexity of associated data. More than 62% of respondents said the complexity of integration with the PLM system has increased over time.

Findings on CAD-PDM/PLM Integration

To help organizations better manage increased product complexity, CAD solution providers have added more capabilities into new releases to directly address integration with PLM platforms. But there is a larger question that remains to be answered: Does better CAD integration with PLM result in increased productivity for design engineers? The data from the current study sheds some light on this question.

Some 61% of the study respondents said these tools have a very high to high impact on productivity. Another 29% felt they have a medium impact on productivity. These results make it clear that engineers are deriving productivity gains from these data management tools. Yet, that said, it is important to understand the benefits of tight integration between CAD solutions and PDM/PLM platforms.

Understanding Why CAD-PDM/PLM Integration Affects Productivity

Engineers benefit from increased productivity when their CAD solutions are tightly integrated with their PDM/PLM platforms. In this section, we will discuss just where these boosts are coming from.

When engineers design a new product, they must keep the requirements of that product in mind as they work. The design phase of the product development process is only complete when the product meets all necessary requirements. This means that engineers must have easy access to the latest requirement documents at every stage of design. This becomes even more crucial when design changes are made. When organizations integrate their CAD solution with PLM, engineers can seamlessly check designs against requirements at every stage of the design process.

It’s not just the Mechanical Design Team

It is also important to note that many stakeholders beyond the mechanical design team participate in product development. These stakeholders also need access to the latest design during the design phase to complete their own tasks. Integrating the CAD solution with PLM ensures that all stakeholders have that access. PLM integration allows them to visualize the latest design without having to install the CAD solution on their computer. Furthermore, as the design engineers and other stakeholders communicate during the design process, all of those communications are stored in one central repository. This provides seamless collaboration between stakeholders as well as vital traceability.

Companies may employ a variety of specialized design workflows to help them develop products more efficiently. PLM facilitates the setup of these workflows. With PLM, executives can easily track the progress of the design work. But given that the main work products involved are CAD models, integrating CAD with the PLM is critical to supporting these design workflows and making sure all stakeholders are on the same page.

These conveniences are a direct result of tight integration between the CAD solution and PDM/PLM. Improved access to and management of CAD data gives engineers a much-needed productivity boost, especially as they work on more complex products.

Conclusion

As modern products become more complex, manufacturing organizations are looking for new ways to boost productivity during product design and development. Lifecycle Insights’ 2021 CAD Productivity Study findings support the idea that tightly integrating CAD solutions with PDM/PLM platforms is one way to achieve this goal. As more CAD solution providers add functionality to better integrate different technology solutions, manufacturers can leverage these capabilities to get the productivity gains they seek.