Isn’t the Product Lifecycle process (PLM) the backbone of Digital Transformations for forward-moving organizations? With PLM as your Product Innovation Platform (PIP) secured and innovation at the forefront of your culture, designing the best product is no longer enough to remain in front! For your

Isn’t the Product Lifecycle process (PLM) the backbone of Digital Transformations for forward-moving organizations?

With PLM as your Product Innovation Platform (PIP) secured and innovation at the forefront of your culture, designing the best product is no longer enough to remain in front!

For your globally dispersed teams/stakeholders, merely having a PIP isn’t going to cut it

They must:

• Speedily manage new product introductions and changes to configurations in order to keep pace with advances in technology and aggressive competition.

• Seamlessly integrate embedded software into mechanical and electronic designs with traceability and governance.

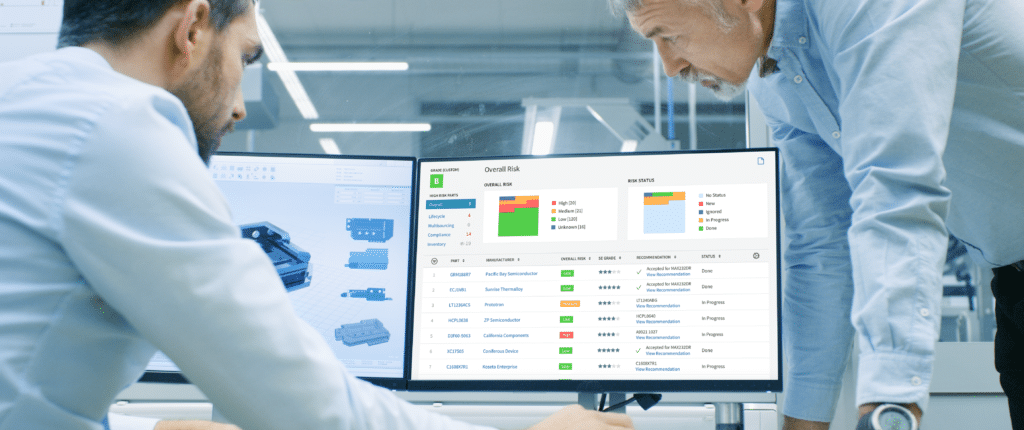

• Mitigate risk across the supply chain while optimizing for cost and quality with new levels of operational flexibility.

The factory must be more agile and work concurrently with engineering even as the number of product variants soars and work rules change to accommodate new safety regulations.

Quality must be built into every product and process. Enterprise quality initiatives depend on driving down the costs of poor quality and minimizing delays in securing regulatory approvals.

The PLM Enterprise Application has quickly risen to become one of the key pillars of manufacturing and the backbone of digital transformation across every industry. As the mission-critical collaboration platform, PLM provides digital continuity, configuration management, and associativity for product data (CAD, software, bills of material, requirements, tests, simulations, etc.).

It automates the standardized processes that help accelerate time to market, reduce costs, and improve quality.

The BOM is changing

It’s becoming more important than ever

When I look at the daily life of a manufacturing organization today, the BOM is the cause of either getting things right or not.

As I talk more & more to our consultants and customers, there’s a huge inconsistency in the manufacturing world – Plenty is working on different disconnected & inflexible BOMs unable to comply with the configurability that customers need to describe in their smarter products of today

Time wasted, double-checking, trying to find what is the right revision & the right BOM that we should be looking for

And, today, as these same organizations try to scale they find it harder to change.

A more complex world

In an ever-increasingly complex world, we’ve got software & IT departments involved in developing products now.

The actual markets have globalized & gotten more complex and so too the BOM has become a whole lot more challenging.

We’re moving away from a jumbled document-centric, CAD-centric view of the bill of material and the way to use it and really moving to having the BOM be the digital product backbone, at the core of everything that happens around your product.

We’re moving to a highly flexible, scalable, speed-to-market, cost-reduction, and supply chain communications type of BOM.

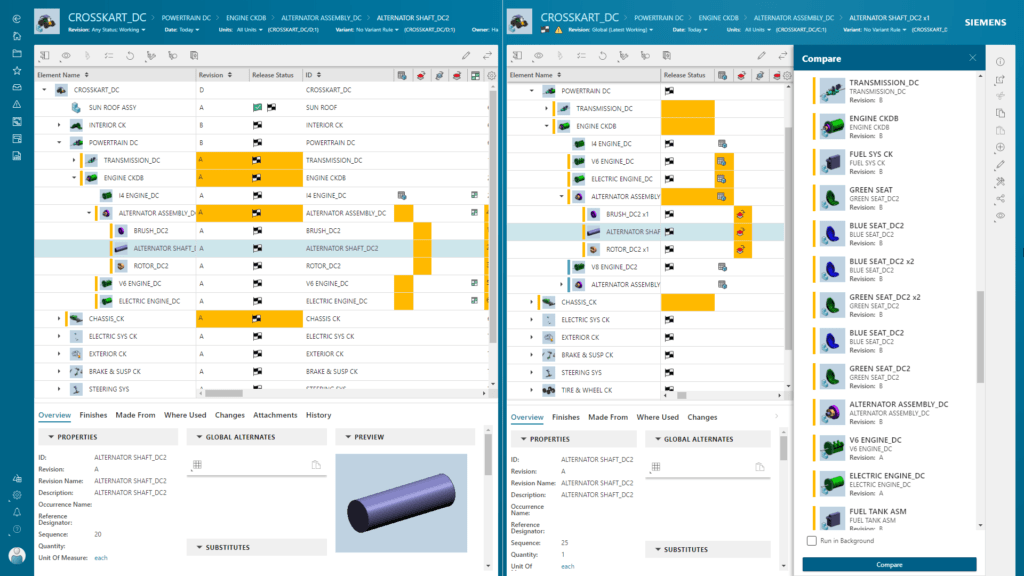

Our products need to be more agile than ever and critical to that is the managing of revisions, configurations & change – BOM Management

It’s so important to be able to have a structured process and be able to manage it in a way that everybody is on the same page, and that all of the changes are communicated well, accurately, and in a timely basis.

The BOM resides in PLM

I believe the answer starts with making the PLM system the natural system of record for design engineering.

It’s where collaboration & change management is happening.

It’s where your product is evolving.

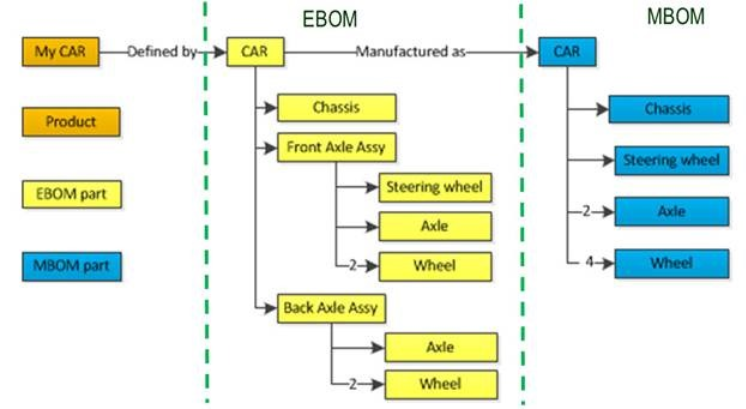

But really the BOM starts in product planning and design, and therefore it’s the most natural, flexible environment in which to evolve the design and then hand off the bill of material to the ERP/MES system for execution

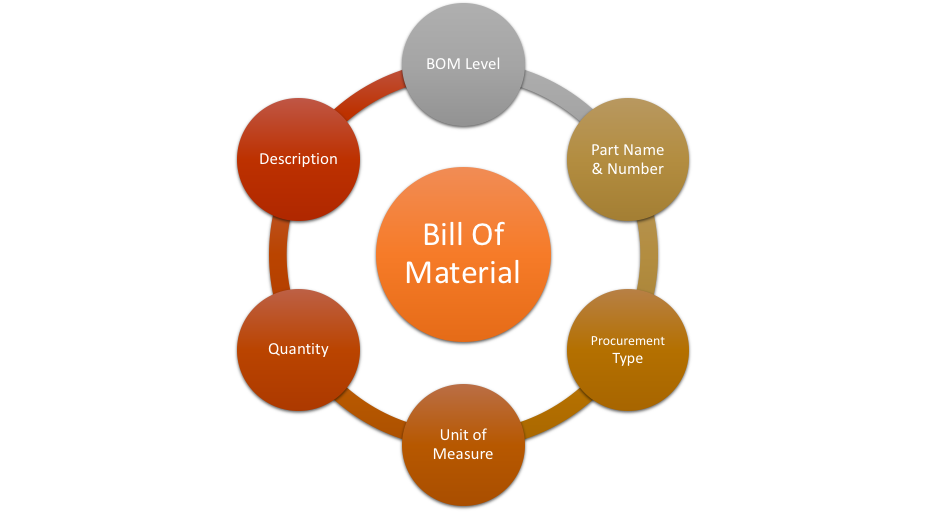

Companies are starting to just manage a lot more than just technical information and specifications within their BOM. There’s so much more to the commercial offering of a product in terms of what the product is, how it’s manufactured, how it’s serviced, but also the materials around it, the product documentation, and service documentation.

UBOM

There’s so much that’s involved in a product. Having it all is of such business value

You understand that if you are changing something in the bill of material, then it’s very likely going to change something in the service documentation or in the manufacturing documentation or if you switch out a part that may have something that will impact the quality plan or the regulatory compliance.

So all of that being connected in one place, this holistic view, is really important.

Moving the BOM away from just something we think of as being part number, description, quantity, and notes, and putting it in a system that allows you to augment it with this rich set of design information, makes it a very natural and easy way to be able to access all the rich design information simply by following the bill of material structure and now you’re following the parts.

CBOM, EBOM, PBOM, MBOM, and SBOM are all associated.

Knowing if you make a change, in engineering, that change has to be able to cascade to all the derivative bills of material in a completely error-free way.

That’s the Unified Bill of Material – The UBOM

Andrew Sparrow

Smarter Innovation & Product Lifecycle Management & Manufacturing: People, Teams & Business Solutions enabled through Change & Technology

Sometimes you need a real expert to help decide what’s next and sometimes you need an entire team and sometimes you need an entire program delivering.

Delivering the entire PLM & Smart Manufacturing application layer, along with integration to ERP and moving your people to adopt new ways of working, is the holistic approach we take. It’s the quality of our people and their experience that makes the difference.

If we can help you through your Smarter Manufacturing journey, you just have to ask

I’m a huge believer in constant change.

Standing still is going backward

Oh, I can “boil the ocean” with the best of them, but let’s not live there. The analysis leads to paralysis. Dreaming of & waiting for perfection is the enemy of execution.

Do something, get some quick wins, and start building momentum.

I like to bring attention to Innovation, Smart Manufacturing, Global People Integration & Human Sustainability – I Blog, Vlog, and Podcast, host a few Live Shows, and love being involved in your revolutionary programs.

I love & thrive in working with some of the world’s largest companies & most innovative organizations.

I’m a big people person & have spent my life meeting as many people & cultures as I can. At my last count, I am lucky enough to have visited & done business in over 55 countries

Source: Andrew

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io