In our blog, The Business Benefits of cloud-native PLM, we reviewed why PLM is more than just a tool for engineering efficiency. The blog covered some of the potential business outcomes, from employee productivity and profitability to managing risk. While Duro PLM is designed to be out-of-the-box and simple to manage, it’s still important to plan well and get multiple stakeholders involved to achieve the best results. This blog describes five important steps to getting the best results from your PLM:

- Form a core team of stakeholders

- Select processes to improve

- Benchmark success and set up an ROI (Return on Investment) calculator

- Review individual steps to improve and build connections with your PLM

- Check-in regularly and showcase milestone achievements

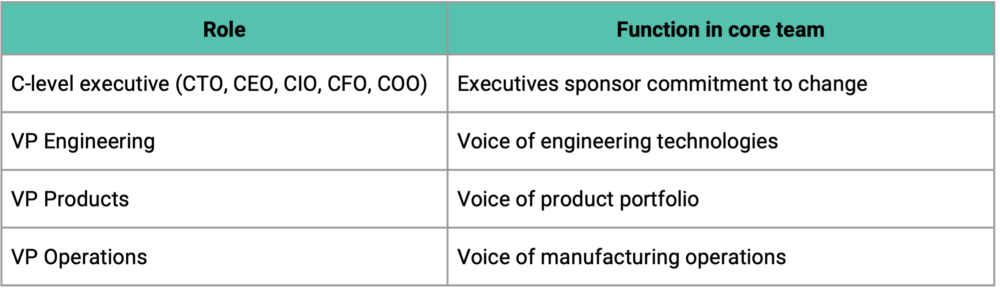

Step 1: Form a core team of stakeholders

Form a core team comprising individual stakeholders from each department. The core team needs to have executive sponsorship to make decisions as well as dedicated time for this work. Each member should have relevant expertise. The core team will work collaboratively to map out the continuous flows of product information while noting discontinuities, unclear spans of control, unmet needs of systems for data, and manual data transfer. Here are some of the example roles that form this core team.

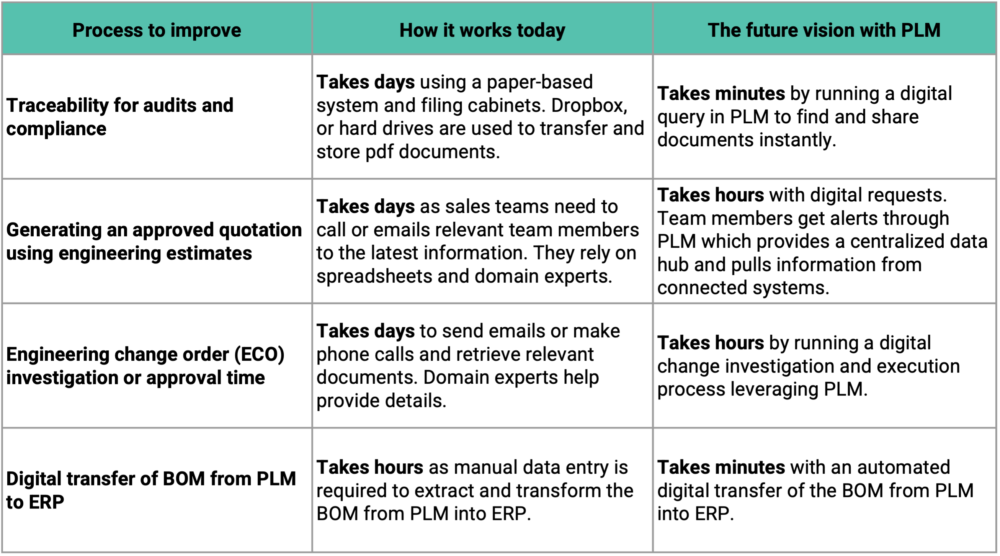

Step 2: Select processes to improve

Step back, pause, and take a detailed look at your end-to-end processes. Select those that could be improved using PLM. Processes can then be ranked according to the effort it would take to improve them versus the ROI for the business. Those with the greatest potential outcomes and lowest effort should be adapted first. These might be those that directly impact sales performance, such as automated sales quotation processes or digital product data sheets.

A powerful method to view the chosen processes is a heat map diagram. This is a matrix comparing ROI along one axis with the investment required, or effort on the other. This visual depiction makes it easier to discuss each process, looking at cost, time, and disruption to achieve the result. Other considerations are interdependencies. For example, it’s not possible to create an automated digital quotation system for sales until digital connections are made between systems such as PLM, ERP, and financial. Executive sponsors should review and approve the documented processes.

Step 3: Benchmark success and set up an ROI calculator

Organizations should take a look at where they are today and consider how they can reach their vision for success. The table below shows that paper-based activities for audits can be reimagined by digitizing workflows using PLM.

Most of the improvements come from time savings which in turn drive productivity. An ROI model can help measure how PLM impacts each of the documented processes. Metrics might include: reducing ECO approval time or improving proposal quotation accuracy. This would be achieved by using PLM to connect sales systems to “back office” financial systems to speed up turnaround.

Step 4: Review individual steps to improve and build connections with your PLM

Work through each step in the chosen process. Focus on how data is connected in the PLM tool and where teams need to be more collaborative.

Let’s use the example of generating a custom sales proposal for a client. The challenges involved were discussed in the previous blog where the sales team was unable to get the proposal to the client in time. This process has a high impact on revenue and can be improved by connecting data across teams and systems. Start by tracking all the individual steps that serve in generating a custom proposal from tailoring a design to updating sourcing information and determining profitability. Review all the different data points and systems being used to uncover challenges and successes. You might then connect data across engineering, manufacturing, finance, and sales systems via your PLM. Design data from your CAD, sourcing data from suppliers, revision updates in PLM, and resource availability in your ERP, which should all be linked. Business logic in the connectors will certify that requests for custom proposals are safeguarded, ensuring that price, margin, and delivery date are reliably calculated.

The first version of the connected systems may be rudimentary and rely on people to view or approve results. However, these can be further automated over time. Ignore organizational silos and assume your organization is a single virtual workgroup with many responsibilities within it. This enables you to remove boundaries between people and roles so that ideas and collaboration can flow efficiently.

Step 5: Check in regularly and showcase milestone achievements

Hold progress milestone meetings to review progress, challenges, and successes. Important milestones should be visible to many product stakeholders. For example, by improving automated data transfer between systems, you can eliminate manual data entry. This speeds up the process, ensures consistency across employees, and makes it more reliable. This change has a direct impact on employee productivity; people will notice and celebrate which builds enthusiasm. Less visible milestones could cause pushback. One example is creating a baseline design structure which requires changes to how engineering BOMs are formed. Figuring out what to do with existing BOMs that don’t match the new baseline design structure is important but impacts many divisions across the business. This work may be unpopular because it’s time-consuming and doesn’t benefit people immediately. Therefore, make sure to share the expected benefits and long-term impact of any project to get buy-in across the organization.

PLM is an approach as much as it is a software solution. Having a core team representing all major business functions not only ensures a common understanding of all stages of work but also ensures “buy-in” across the organization. Setting goals and a vision for improving different processes will make improvements tangible and compelling. All stakeholders should be aware of how PLM enables those business outcomes so that they can prioritize it as a vital enterprise solution.