What Is Product Lifecycle Management?

Product lifecycle management is the process of managing how and when products are presented to the market, from development to growth, maturity, and decline. PLM is used to develop strategy and make decisions around your product portfolio. Product lifecycle management is used to determine pricing, marketing, promotions, and selling strategies, as well as expansion and discontinuation plans. It’s a complex process and involves technology to help you create, capture, manage and leverage your products to help your business maximize profits.

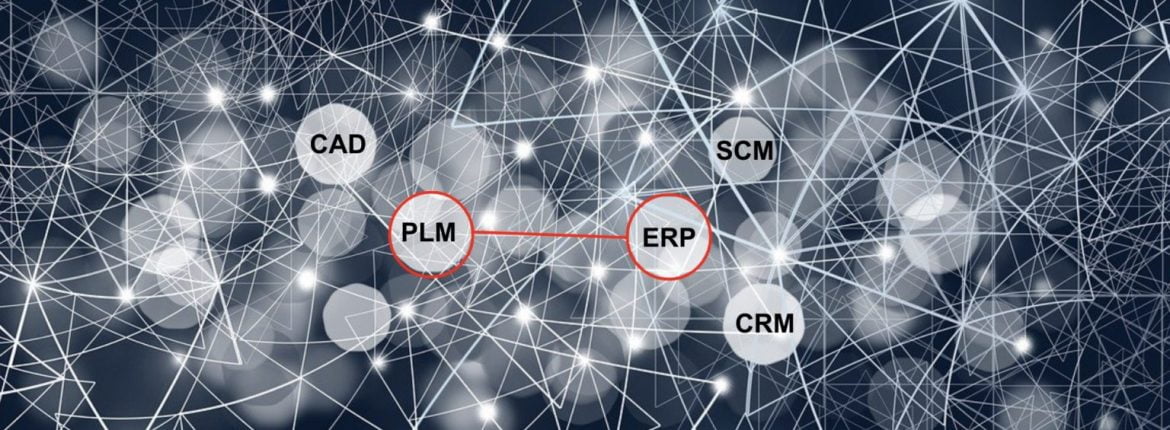

PLM strategy is most effective when supported by robust ERP software. Because PLM includes elements of product development, supply chain, customer relationship management (CRM), and more, software that can integrate these functions into one complete system connects the information from across the organization you need to improve processes.

Key Takeaways

- PLM is the process of creating and updating products and bringing them to market quickly. It includes the manufacturing and marketing of the product.

- PLM brings together disparate sources of information, data, and teams to work more collaboratively and efficiently.

- PLM is a strategy to manage your business’s intellectual assets and leverage them for process improvement and competitive advantage.

- Enterprise resource planning (ERP) is a key component. It’s used to collect and analyze data from different areas of your business involved in creating, manufacturing, and distributing the product.

Product Lifecycle Management Explained

Most products are complex and are made up of many components or raw materials that also require assembly. The bill of materials (BOM) could be considered the recipe for your product. It explains where materials will be purchased and how products will be put together. A common misconception is that the BOM is the entirety of a product’s lifecycle. When in reality, it’s an important step in any product’s lifecycle, but there’s more to a product lifecycle. It doesn’t account for other aspects like design, distribution, sales, and more, which is where PLM comes in.

With the help of different ERP modules, such as inventory management and supply chain management, you can centralize information and connect each of those other aspects of a product’s lifecycle. The modules help to reduce redundant and labor-intensive work, provide access to real-time and accurate data and bring everyone from conceptual design to product engineering and customer relationship management together in one ecosystem. PLM is traditionally used by manufacturers who employ designers, engineers, marketers, and others, work with already established products and develop new products.

Why Do Companies Need PLM?

Complexity is a major concern for businesses. This complexity is only growing between product design, supply chain management, distribution, and customer feedback. And at the same time, growing global competition is driving prices down, regulations are constantly shifting, and your business needs quick-to-market, high-quality products to turn a profit.

To succeed, consider each step of the process in a product’s lifecycle, how they relate to one another and how to bring together the technology to manage each step of the way. Effective PLM helps organizations capture knowledge proactively, encourages and facilitates teamwork, and provides easy access to knowledge, expertise, and information across the organization to reduce time to launch and accelerate go-to-market.

The Elements of Modern PLM

In addition to inception, design, engineering and manufacturing, and other areas, PLM strategies leverage insight from the marketplace to improve existing products and launch new merchandise. There are important elements of PLM to consider, including the different stages of a product’s life cycle. What are the five stages of the product life cycle? Implementing information and communication technology, mapping processes, managing production methods, improving product innovation, and speeding up commercialization.

- Implementing information and communication technology (ICT): All of the necessary platforms, architecture, and standards necessary for PLM make up ICT. The PLM process would not be possible without it, and the first step is to break down silos so data about your products, including design, supply chain information, marketing, and sales, are connected and can be accessed in a single location.

- Mapping processes: Map all of the people, teams, and organizations needed in the lifecycle of your products. Identify the skillsets needed for each step of the way. List key stakeholders. Laying out the plan for how a new product will be designed, developed, and distributed and making it available to everyone involved helps clear confusion and make PLM effective.

- Managing production methods: Manage product development data and processes to accelerate time to market while balancing cost, quality, and compliance.

- Improving product innovation: Build a pipeline of ideas that can be developed into valuable offerings.

- Speeding up commercialization: Find sticking points that are slowing the development of new products and place special emphasis on them to speed up time-to-market. Standardizing parts and processes can help. As a developing relationship with manufacturing and parts partners.

What Is the Product Lifecycle?

The product lifecycle starts with an idea. That idea undergoes research and market testing and may be made into a product. That product then needs to be marketed and sold and eventually improved upon for new iterations. What are the 4 phases of the product life cycle? Product development, growth, maturity, and decline.

- Product development: The first step of the product lifecycle; involves planning, conceptual design, product and manufacturing engineering, and simulation.

- Product growth: The product is released to the market. Distribution ramps up, along with marketing and sales. Ideally, the demand increases. But that also means there will be increased competition. This is the early stage of the product, and you are still working on brand and/or product recognition and market share.

- Product maturity: Your product is now widely available. You may need to make adjustments to packaging or adjust marketing to appeal to new segments.

- Product decline: As competition increases, you may have passed peak demand. It might be time to develop an exit strategy or reimagine the product to identify areas for opportunity, including new markets or new iterations that bring improvements or can inspire more excitement and demand for your product.

Product Lifecycle Examples

Let’s take the fictional company Dog Cone through the product lifecycle stages.

- Product development: The idea for a new, healthy ice cream treat for dogs leads to the creation of the Dog Cone company. The product is designed and tested and goes through regulatory controls. By aligning all of the teams, from the supply chain to manufacturing and marketing, Dog Cone is able to create, source, and distribute the new dog treat efficiently. The product rolls out at just a few strategic boutique pet shops in key influencer markets.

- Product growth: More pet stores, including chains, begin to carry the Dog Cone treats. Updated packaging is rolled out, and marketing continues to find new distributors.

- Product maturity: New competitors have entered the market with similar products, and peak demand is reached. To stay competitive, Dog Cone introduces new flavors, varying sizes, and exciting new packaging.

- Product decline: With increasing competition and market saturation, Dog Cone takes lessons learned to expand its business. PLM helps keep the Dog Cone team aligned. The supply chain benefits from standardizing procurement. Planning, conceptual design, product, and manufacturing engineering all benefit from continuous learning and software integration.

Product Lifecycle Management Stages

Another way of looking at the product lifecycle is beginning, middle and end. By establishing the processes and clearly communicating each step of the way, you can help coordinate efforts and minimize wasted efforts. Learn more about the three different stages:

- Beginning of life: Starting with conception and development, this phase includes planning, design, and manufacturing engineering. Marketing and promotion ramp up, and the focus on getting the product to the consumer starts.

- Middle of life: Congratulations, your product has been manufactured and is now being used by your customer. You’ll start to improve production and distribution processes, gather feedback from consumers and track things like maintenance rates.

- End of life: The market may have become saturated. Or perhaps your product is now obsolete. It’s time to plan your production end to avoid wasting stock. Another option is to examine ways to reinvigorate your product through iterations, redesigns, or find other ways to stay relevant.

Benefits of Product Lifecycle Management

There is a direct tie between information integrity and the effectiveness of an organization or its ability to respond to a problem. About half of product development and commercialization resources are wasted, and a whopping 90% of companies are slow to market and over budget.

PLM enables your organization to manage the information so that it’s clear, concise, and valid. With accurate data and better collaboration, companies can get products to market faster, ramp up to full production more quickly, capture more market share, price products accurately to continue to deepen market penetration, and find ideas for new products and functionality.

In sum, PLM allows businesses to save money and get to market faster by:

- Managing information all in one place

- Keeping data accurate

- Collaborating more easily

- Getting to full production faster

- Capturing more market share

- Pricing accurately

- Finding new ideas for functionality and product

Challenges in Product Lifecycle Management

In trying to accommodate more complex product development processes, organizations struggle with disconnected systems, processes, and departments, as well as issues with data quality and frequent engineering change orders. Disparate software systems can drive up costs because of inefficiencies and slow product commercialization.

To summarize, some of the biggest PLM challenges include…

- Disconnected systems, processes, and departments

- Poor quality data

- Frequent change orders

- Increased inefficiencies with separate tools

To overcome these and other challenges, eliminate data and information silos with comprehensive ERP software that includes modules for supply chain, manufacturing, and other teams. Other helpful tools include setting enterprise-wide metrics and goals and adding end-to-end process owners to decrease handoffs between teams. Getting top-level buy-in from the outset can also help with the implementation of new or changing policies and software.

Measuring & Evaluating Product Lifecycle Management

One of the benefits of PLM is bringing together traditionally siloed teams to be more unified and work toward common goals, financial metrics, and other key performance indicators.

Product Lifecycle Management Metrics

Here are some metrics to help measure the effectiveness of your PLM efforts:

- Team productivity: Productivity across the board should increase with better collaboration and information.

- Quality of output: Strong PLM reduces process waste and improves product quality, including improved first-pass yield or how many units are produced without defects.

- Time-to-market efficiency: PLM helps organizations hit product launch target dates by standardizing processes and centralizing information to improve efficiency.

- Product development budgets: Improved efficiency with integrated ERP software modules cut down on labor-intensive processes and make your teams more efficient. This helps control costs.

- Revenue from new products: High-quality PLM results in better-quality products that get to market faster, driving up revenue.

- Cycle time: Track the time it takes to develop and deploy new products. Include everything from design to testing and marketing.

- Product life: How long is the product used by customers? Compare that to historical data and benchmark for future efforts.

- Product waste: Examine how much waste is generated per product developed.

- Product reliability and warranty claims: How durable are your products? Look at how many are found to be flawed or faulty, and track the number of warranty claims per product sold.

History of Product Lifecycle Management

Having a single repository of data to enhance productivity was the aim of the first PLM when it was created in the American automotive industry in the 1980s. As cars became increasingly complex, manufacturing processes and costs were rising, making it difficult for smaller automakers to stay relevant. American Motor Company, the makers of Jeep, centralized their data and computer-aided design (CAD) as a first step in creating PLM.

A major benefit of having a central repository in the automotive industry was that elaborate engineering work could be completed once and used for various models with similar attributes. The whole supply chain benefited from this design because the procurement of parts could be standardized.

From early roots in managing product data, PLM capabilities have grown to include quality systems, sourcing, project and portfolio management, customer resource management, analytics, and after-sales service.

Successful PLM With Integrated ERP

PLM is a business strategy to continuously improve products and innovate with new offerings. And it’s supported by a series of integrated software application solutions to address single stages of a product’s lifecycle or connect different functions. Although manufacturing processes are an important emphasis, PLM strategies and software include other modules, including marketing, sales, and portfolio management. Enterprise resource planning software helps you gather, manage, monitor, and report all the data necessary for a successful PLM. ERP solutions connect inventory and order management, accounting, human resources, CRM, and other steps in a product’s life cycle in one system for your entire organization.

Product lifecycle management is about connecting teams, information, and strategy across the entire life of a product. PLM is a discipline that encourages employees to look at the overall goals of the product and business, and it’s supported by impactful ERP software that gives them the technology and tools to collaborate, share information, and more efficient design, develop, source, and sell a product. Modern ERP software is vital to the process. It reduces manual processes, standardizes data, and is the engine that drives effective PLM.