Switching from the ubiquitous 2D drawing to a modern 3D representation of your Production layout has its costs, but the benefits can outweigh them

Why design production layouts in 3D?

Most of our readers are aware that 2D drawings were once prevalent in Product Engineering. Car design, for example, was recorded on 2D drawings. In contrast, today, virtually all capture of car design is in 3D. For example, 3D, among other benefits, clearly conveys how the car, or its components, look.

Similarly, an evolution is quietly taking place in Production Engineering.

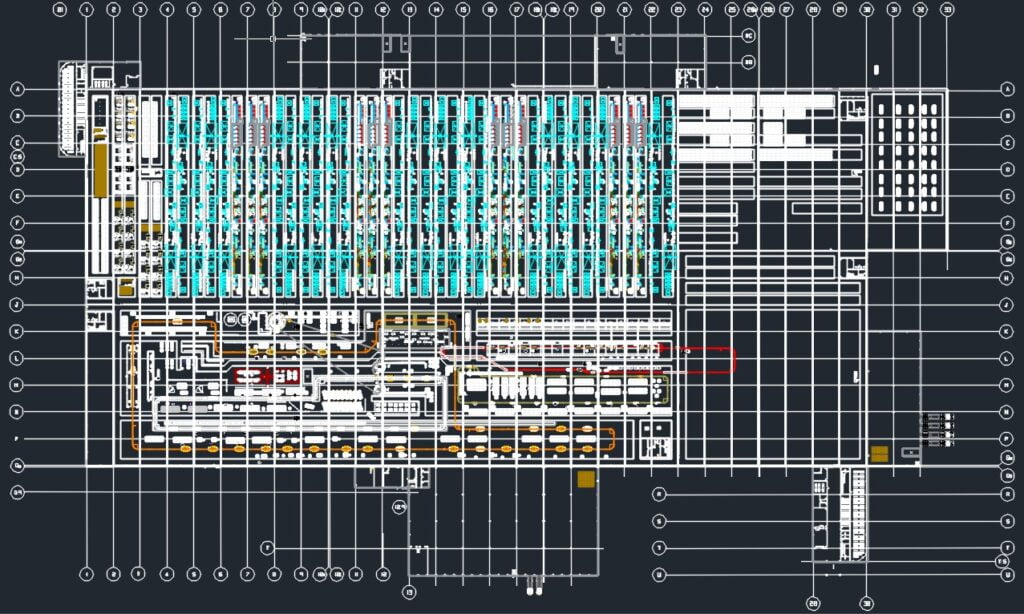

A production layout in 2D

A production layout in 2DLooking at the 2D production layout above, we can assume this evolution started with similar benefits in mind. For instance, presenting production lines in 3D looks better. While 2D drawings hardly convey excitement, 3D proposals leave a strong impression on the executives asked to invest in a new production line, or prospects asked to select your proposal.

A production layout in 3D

A production layout in 3DIs it time to switch to Production layouts in 3D?

In other words, if your team is tasked with submitting layout proposals, and you are not already creating your Production layouts in 3D, it is definitely time to switch. Perhaps your executives are already asking for it. Your competition most likely already switched.

Even if your team is not tasked with creating winning proposals, the benefits of switching to 3D far outstrip the convenience of staying in the 2D world. In addition to clarity, laying out your Production lines in 3D, opens up the world of the Digital Twin of Production with all of its associated benefits. The rewards extend beyond your team. They flow to additional parts of your manufacturing organization.

A dedicated 3D Layout Authoring application, like Siemens Line Designer, will deliver additional benefits:

- Work efficiently and effectively as you design your production layouts in 3D

- Evaluate reach of robotics and clearance of equipment, animating robotic arms and machine access doors

- Associate business data and properties with the equipment

- Creating tailored reports cutting across associated business data

- Compare your layout against your factory laser scans to ensure additions will fit in – just add the laser scans in

- Launch the scene into Virtual Reality to have a realistic feel of the layout.

- Create installation drawings from your 3D layout

- Maintain an accurate list of equipment as it added to the layout …

- … and much, much more.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io