NX Validation Improvements:

- Quality Dashboard for Check-Mate

- NX/Open checkers improvements

- Provide availability of HD3D objects for diagramming applications

Please read on to find out more and be sure to check out our video demonstration on these updates.

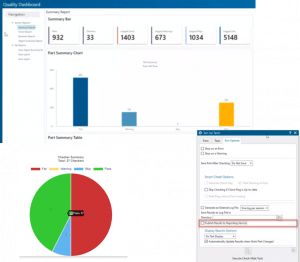

Quality Dashboard

The new quality dashboard for check-mate replaces the Java Qdashboard. This is an on premise tool providing the ability to quickly summarize checker results and display them in a variety of graphs and charts,

What’s included?

- Out of the box summary reports

- Ability to create custom reports

- Results per part file or checker

- Very fast search and population of data

NX/Open support added for Check-Mate Checkers

Check-mate checkers can be created using NX/Open in all supported coding languages.

What’s included?

•Custom Checkers can be written with all major Check-Mate functions: Set Up, Customize, Execute, Documentation, Save Results, Smart checking and batch mode

•All checker results are available in HD3D and can be saved into Teamcenter

HD3D Visual Tag Support for Diagramming Tools

HD3D framework enables assigning pointers to tags which provide visual cues indicating important information. This information is available and can be browsed.

What’s included?

•Made this capability available to diagramming applications such as: P&ID Designer, and Automation designer

•Allows these applications to convey and persist results providing users with better information about their design thus leading to improved quality and reduced time spent doing manual reviews