Digital twins, AR/VR bring simulation benefits to industrial automation users, says Siemens

Among the challenges that COVID-19 posed to manufacturers in 2020 was the need to plan for and maintain optimal production levels without sacrificing employee safety. As manifested in simulation and robotics, the convergence of digital and physical worlds provided tools for industry to adapt and even thrive in difficult times.

Two sets of technologies can help manufacturers during the pandemic and beyond, according to Siemens. By enabling managers and employees to see a factory’s configuration while working from anywhere, digital twins (DT) can enable global organizations to adopt best practices remotely, it said. Staffers can see work orders on a machine via 2D/3D cloud renderings and access an entire digital twin of the factory floor.

In addition to digital twins, augmented reality and virtual reality (AR/VR) can provide employees with the same level of visibility as in-person testing, said Siemens. The use of virtual factory acceptance testing (FAT), virtual commissions, and remote monitoring has been accelerating, in part because of the pandemic. AR/VR can provide enterprises the benefits of cost and time savings and enhanced social distancing.

Vincent Guo, Ph.D., director of business development, strategy, and portfolio management, for digital manufacturing at Siemens Digital Industries Software, responded to the Robot Report’s following questions about trends around digital twins and AR/VR.

Getting started with simulation

How can digital twins benefit operations that are just starting to automate? How can those who already use robots benefit?

Guo: Digital twins can help a newly automated company understand the feasibility, estimate potential improvements, and reduce risk during implementation, to name a few benefits.

For example, one can use the digital twin to understand whether it is possible to use an electro-mechanical system — typically a combination of robots, mechanical structures, servo motors, and control systems — to perform the same task by human operators. Such simulation is then used to validate the mechanical structure’s design, the setup of the automated cell, the control logic to perform the manufacturing process, etc.

Once those elements are understood fully, the manufacturing will place the hardware’s order and build the automated production line according to the validated design. This can greatly improve the financials, as the hardware procurement happens later, and commissioning takes less time. It can also reduce deployment issues since problems can be identified before the hardware is even purchased and bring in cash quicker due to faster deployment of production.

For companies that have already incorporated robots, digital twins of production allow users to do the following:

- Implement a company standard to manage current and future projects for sustainability. For example, a formerly validated design can be reused, so generating new designs can be more efficient.

- Retrofit existing production for the next product in the digital world without interference to ongoing production.

- Use insights coming from existing products and production. These will be important inputs to the digital twin to improve the next-generation product.

For example, JR Automation, a supplier of intelligent automated manufacturing and distribution technologies, uses digital twin technology to virtually commission a robotic cell developed for material handling applications.

How has simulation software evolved in the past year?

Guo: Like CAD tools, the digital twin of production evolved from 2D to 3D. Today, simulations can be viewed in VR, supporting remote collaboration. With more integrated elements into the simulation, what once started with pure mechanical simulation based on time sequences now adds electrical signaling to validate the control logic.

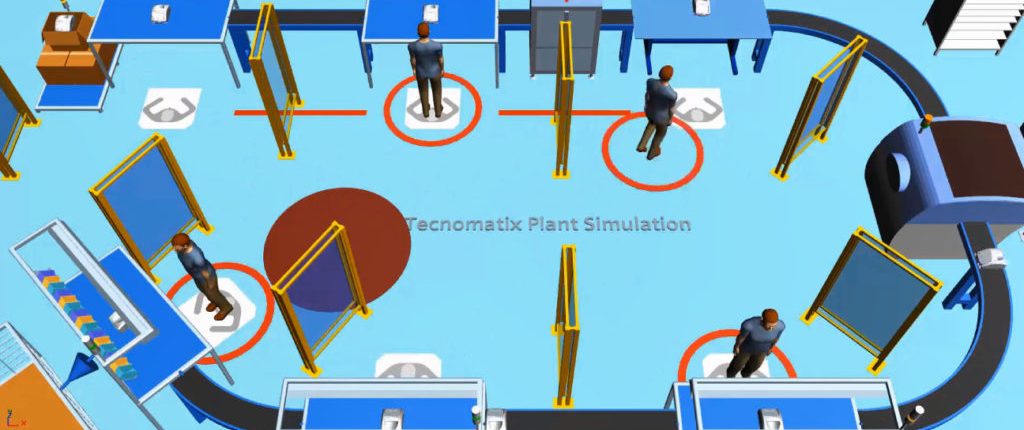

In the past, the simulation was focused on the behavior of specific machines. At the same time, today, one can simulate the entire system’s behavior, including interfaces between machines, AGVs [automated guided vehicles], and people.

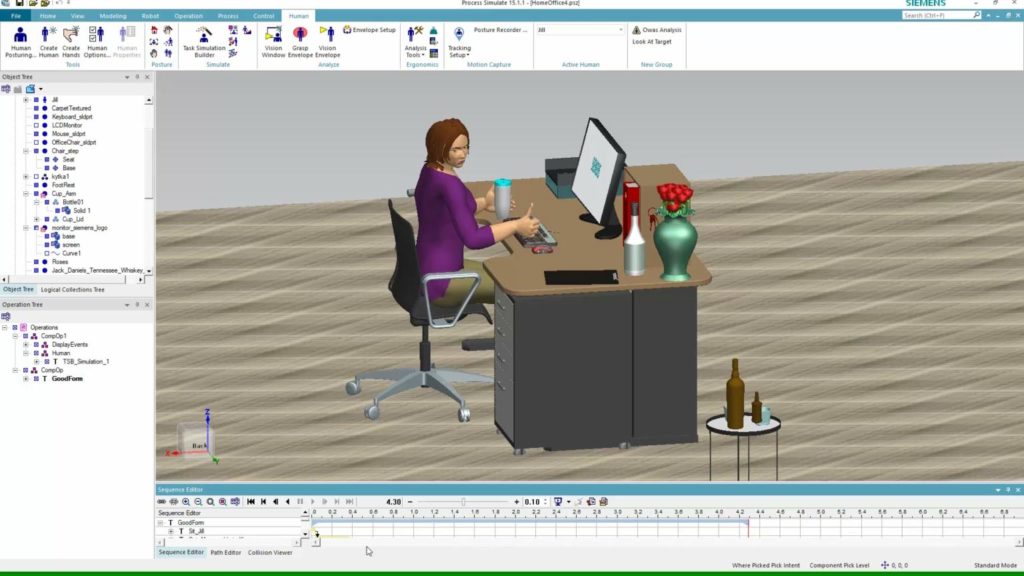

Human operations simulations went from static to dynamic. Today, we can detect potential injury to various parts of the human body during operation, even while working with collaborative robots. Simulation can provide added value on top of reality, with strong tools providing the ability to perform what-if analysis. In the future, we plan to bring in more artificial intelligence to the simulation platform to make the design and validation of a flexible production system even easier.

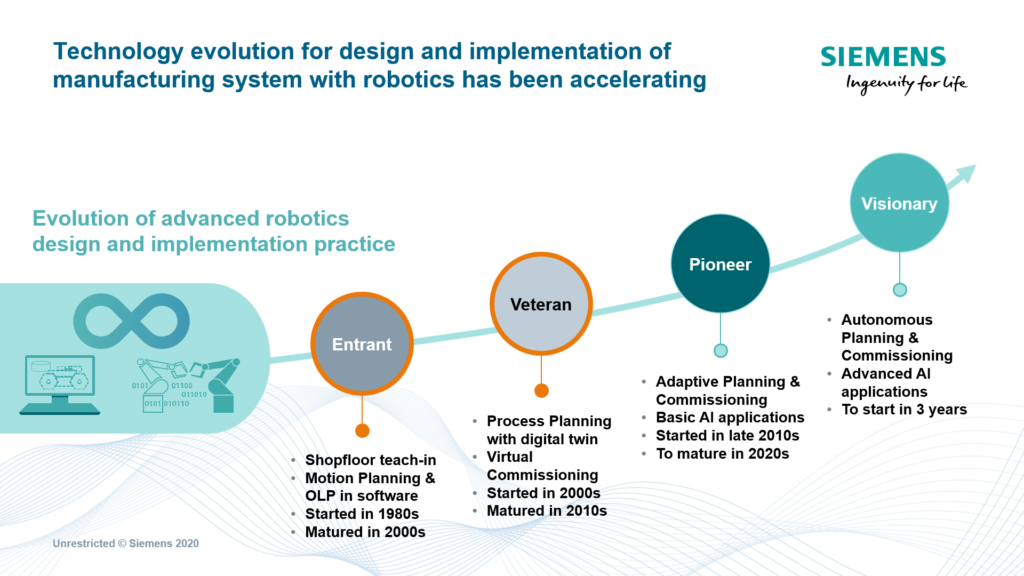

The Siemens Digital Industries Software (DI SW) division has provided solutions to the robotics and automation segment for four decades. We developed an evolution roadmap for robotics manufacturing system design and deployment from our experience, observation, and vision.

Source: Siemens

Robot simulations require accuracy.

How accurately do Siemens’ systems model the latest robots as part of factory operations?

Guo: Mechanical modeling of the robots is as accurate as of the hardware itself. The control signals have the ability to be 100% accurate since they are digitally perfect. The robot’s motion in space and time can be modeled roughly around 99% accurate, as per the international Realistic Robot Simulation or RRS standard. Siemens works very closely with robot vendors to ensure that our simulation software provides comprehensive support to global hardware brands.

Siemens is unique because it provides simulation hardware for manufacturing system engineering while simultaneously supplying hardware such as PLC [programmable logic controllers], HMI [human-machine interface], and motors that is mandatory for automation lines. Therefore, a Siemens customer would enjoy the value from both software and hardware in an integrated solution to ensure seamless workflow from design, commissioning, and operation.

What are some examples of digital twins or AR and VR helping manufacturers?

Guo: In aerospace companies, the order changes rather frequently, and batches are small. Operators may need to change operations quickly, which is a challenge in memorizing new work instructions. AR is a useful tool in guiding human operators through complicated and changing assembly jobs.

One can design and validate the assembly operation with Siemens’ simulation tool and use those as electric work instructions (EWIs) to distribute to the shop floor. Since the EWIs are connected to the product in the databases — like the EWIs in a PLM [product lifecycle management] system is connected to the MES system — they are automatically shown to the correct operators on the shop floor.

Augmented reality for robot-related engineering is useful when a part needed to finish the physical world design is missing. For example, when designing a robotic process working with a part on a fixture, any of the three can be missing: the robot, the part, or the fixture. Instead of waiting for all physical assets to start the work, AR technology can bridge the gap. The user can project the robot with AR to the physical part to make the sure clearance or validate the fixture before sending the order to the factory.

As we consider human operations in the manufacturing simulation, technologies like motion capture and VR are also used. For human operations, VR can provide an immersive environment that is especially useful for design review, project evaluation, and training. One can even use motion capture with VR to enhance the experience.

Can you give an example of AR/VR being used to plan or manage robots? Do they also account for people in processes?

Guo: Once one finishes designing a robot station in our simulation software, the user can jump directly into it via VR. The user can view the robot’s motion, manipulate the robots, and collaborate with remote colleagues via VR, without risk of injury or damage to equipment.

Other VR applications include design review and issue detection and logging, safety assessment in robotic stations, and card-boarding digital mockups. VR can be used with motion capturing for human ergonomics validation and time-calculation.

Simulation can account for humans in processes. Source: Siemens

How has the pandemic made it more difficult for managers to supervise production? Aren’t the floor workers more affected?

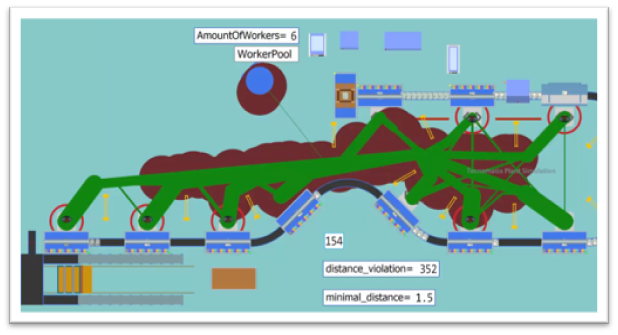

Guo: Indeed, there is more to consider today due to the pandemic’s effects, especially given the intensive human labor on facility floors. For example, we want to ensure operators are protected by enforcing safe social distancing. We can retrofit the production system and validate the new layout or work sequence to meet correct distancing guidelines.

In the image below, the green area indicates the routes the operators can take during work hours. The solid brown indicates an area where two operators can be very close to each other in this production cell and are generated dynamically by simulating operators’ actual movement on the shop floor.

Source: Siemens

Has Siemens seen an increase in demand for digital twins and AR/VR during the pandemic, or do businesses need to be more aware of these technologies?

Guo: The need for digital twins has increased. As customers reduced their physical presence, digital methods to facilitate manufacturing design, deployment, and operations went from “nice to have” to “must-have.” Siemens has had customers tell us they wish software deployment in their companies happened earlier.

For instance, plastic-injection mold company iMFLUX used a Siemens digital twin to retool for making COVID-19 tests quickly.

Also, we do see increased interest and openness to AR/VR in all industries. VR is needed for multi-site and multi-state collaboration due to travel restrictions. One Siemens customer is conducting VR review sessions with six different international locations simultaneously, with up to 15 VR glasses being used in each session.

Prospects for digital twins, AR/VR

What are some areas where AR/VR or digital twins still need work?

Guo: The user experience of AR/VR, as well as the accuracy of the hardware, still has room for improvement. For example, the VR headset itself is heavy, has low battery life, and presents challenges for glasses. Both VR and AR devices provide spatial accuracy in centimeters. This level of accuracy limits the use cases, especially when mechanical precision is critical.

Digital twins will keep evolving as new technology and products are continuously introduced. Digital twins work best when a fully connected digital thread is present – connecting product design, manufacturing engineering, production shop floor, and product usage. This is an area that both technology suppliers and users need to work on to exploit the digital twin’s full potential.

Of course, we hope the COVID-19 pandemic ends sooner rather than later, but what trends do you expect to see in using these technologies next year?

Guo: The COVID-19 pandemic has accelerated the need for the digitalization of manufacturing more than ever. Many companies have realized that a comprehensive digital twin for manufacturing is key for responding rapidly to supply chain shifts, capacity rebalancing, and production footprint management/optimization.

Cloud offerings are key to supporting distributed work environments for engineering and manufacturing to collaborate across product development, manufacturing engineering, and factory locations. Prescriptive industry-based SaaS [software-as-a-service] solutions that Siemens Digital Industries Software offers are one of the key technologies that will be critical in 2021. Siemens has started to allow customers to use our solutions and products as prescription or SaaS to help them reduce cost and recover quickly from the loss caused by COVID-19.

The trend of automation with advanced robotics started before COVID-19 due to the reduced cost of robotic technology. But the pandemic encouraged manufacturers to accelerate this transition, and there is increased demand for autonomous manufacturing and logistics. IoT [Internet of Things] connectivity and AI are becoming key to optimizing individual machines’ performance and utilization, robots to entire machining lines and factories. These tasks are only possible with a comprehensive digital twin of the production.

Source: The Robot Report.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io