Developing Solid Edge OEM solutions

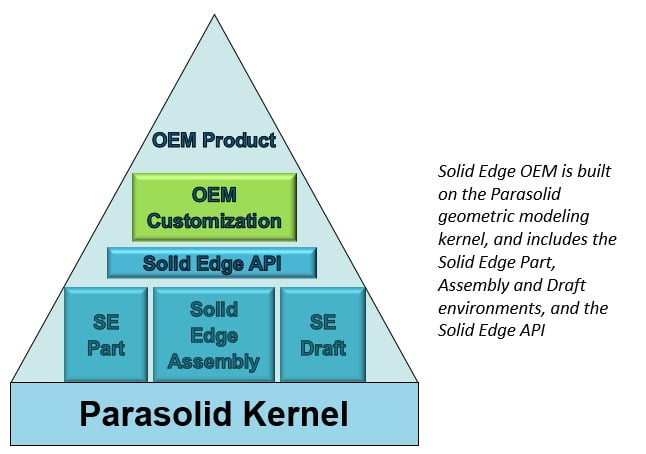

Solid Edge OEM is a comprehensive CAD software toolkit that allows technology companies to create their own tailored software applications based on a comprehensive mechanical CAD solution. Developers can use the Solid Edge API to create custom capabilities that meet the requirements of their end-users. They can also add their own user interface features. These include splash screens, ribbon bars, and docking panes, resulting in a distinctive branding and look-and-feel solution.

Many different companies are using Solid Edge OEM to deliver specific applications to their customers. Examples include a manufacturer of 3D Printers and 3D Scanners, a developer of a robot programming interface for the educational market, and a company currently focused on 2D CAD.

The Solid Edge API (Application Programming Interface) enables the reading and manipulating data in the Solid Edge Part, Sheet Metal, Assembly, and Draft environments. Solid Edge exposes graphical objects and features that are the building blocks of its 3D models, 2D drawings, and associated text and data elements. These exposed objects can be accessed using the API with different programming languages, including VB.Net, C Sharp, C++, and Python.

Leading developer describes automation using the Solid Edge API

I spoke recently with Tushar Suradkar from CADVertex Solutions in India. Tushar is a leading developer of applications based on Solid Edge, and he gave me some insights into his work. “The API opens up many possibilities for how a developer can customize Solid Edge. For example, automation of common design tasks is one area where the API is very effective. Integration of 2D and 3D Solid Edge CAD data with other Windows-based applications, such as Microsoft Excel or Word, is made dramatically easier by using Solid Edge’s exposed objects,” explained Tushar.

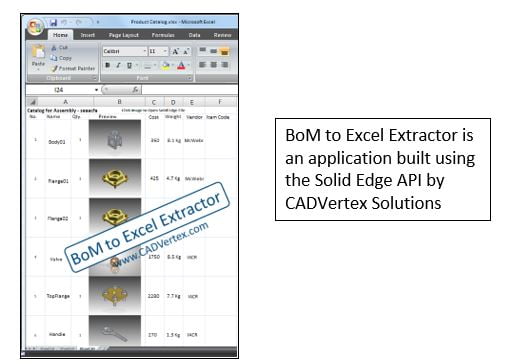

Application example: Bill of Materials to Excel report output

One of Tushar’s recent projects has been to create an application that processes the bill of materials (BoM) and parts list data created in Solid Edge. The application formats this data into Microsoft Excel, where it can be accessed by other departments and by 3rd party software applications. Tushar explained, “Manual extraction of data from bills-of-materials and parts lists can be a time-consuming process for manufacturers. This is true, especially when every revision to a part requires the data to be re-extracted. A manual process is also prone to errors. Automating repetitive tasks and minimizing human intervention must greatly benefit time, cost savings, and reliability. The Solid Edge API has been an excellent tool to create this automated solution for my customers.”

Tushar has developed and implemented several BoM to Excel extraction programs over the years using the Solid Edge API and .Net languages like VB.Net and C Sharp. A specific example is an automated solution for a leading toy manufacturer in Germany. This solution creates product catalogs in Excel from parts lists in Solid Edge Draft and displays them in custom worksheets in Excel. The solution extracts information like part names, description, material, weight, and custom properties like cost and vendor. A thumbnail image of the component is also placed in the Excel worksheet. The customer uses the report to facilitate their downstream operations like material estimation, costing, and purchasing.

Find out more about the Solid Edge OEM and the Solid Edge API

Interested in finding out more? You can download a data-sheet or register your interest in Solid Edge OEM. Or you can view full documentation and examples for the Solid Edge API. You can also contact Tushar at info@cadvertex.com.

Are you using the Solid Edge API? We are always interested to learn how our users and developers are using the API. You can add your comments here!

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io