Go to our sales space to expertise your complete manufacturing technique of a re-engineered steering knuckle for an electrical vehicle (EV), focusing on optimizing the manufacturability, weight, efficiency, and value. The eRod, a progressive Swiss electrical sports activities automotive, reveals how Siemens cloud-based software program options and IoT-enabled machine device applied sciences revolutionize manufacturing with options from digital twin expertise to additive manufacturing and CNC machining.

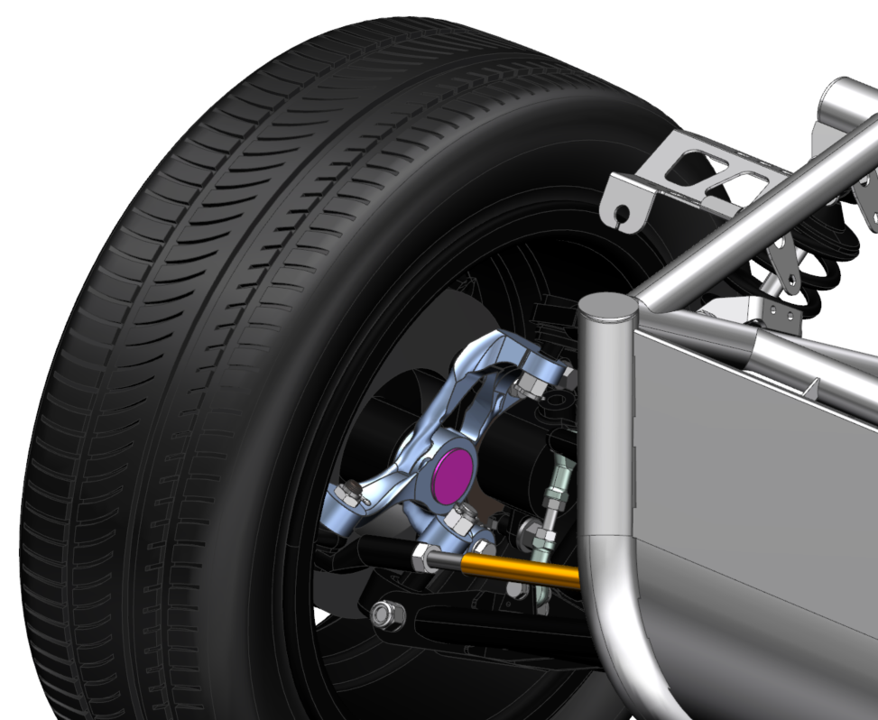

As a part of the end-to-end digitalization demonstration, we show the manufacturing of a topology optimized and lightweight weighted wheel knuckle for {an electrical} car – the eRod.Picture courtesy of KYBURZ

The muse of a high-quality manufacturing course is at all times within the design. Consequently, an increasing number of firms use additive manufacturing as their guiding blueprint, wasting much fewer supplies and optimizing value financial savings for actual manufacturing. Producers can produce large-scale components with an industrial additive manufacturing software program, from design to post-print validation. For the automotive {industry} particularly, the shift to electrification makes lightweight building and sustainability targets much more prime thoughts for producers. These challenges might be addressed by way of a holistic manufacturing course beginning with the half conception and persevering with proper as much as the manufacturing collection utilizing Siemens interoperable software program purposes and superior {hardware}.

A simulation-driven design like topology optimization ensures that the optimum half is created with a minimal quantity of the fabric. NX additive manufacturing permits producers to create optimum half designs with built-in generative engineering instruments like design area exploration. For the eRod, this resulted in a progressive design of the steering knuckle, lowering its weight by 45% and enhancing its efficiency so that it will probably higher deal with stresses. By hollowing out the again of the spindle and smoothing out the knuckle, vital weight discount and enhanced efficiency had been achieved, all whereas guaranteeing that the half’s structural integrity was not compromised.

Topology optimized and light-weighted steering knuckle of the eRod.

The Siemens Xcelerator portfolio permits uninterrupted workflow by having design built-in into NX, making for a seamless handoff to the subsequent stage: the manufacturing engineering course. Uncover how NX CAD, NX Additive, and NX CAM software work with the newest machine device applied sciences to create an end-to-end digital manufacturing solution by changing a 3D half mannequin into an actual half put in on an EV.

Get the complete expertise at our IMTS 2022 reveals. You can find Siemens in two cubicles: #133346 within the Controls-CAD-CAM pavilion positioned within the East Corridor, and #433028 within the Additive Manufacturing pavilion positioned within the West Corridor.

Keep tuned for the newest information on this industry-leading occasion! We hope to see you there.