Data analytics in the manufacturing industry

The manufacturing industry is undergoing a digital transformation, and data analytics is playing an outsized role.

Industry 4.0 smart manufacturing solutions have made it possible to harness the massive amounts of data machines and equipment produce every day during normal operations.

Sensors collect valuable machine, operational, and system data, and using Industrial Internet of Things (IIoT) technology, it’s sent to cloud-based analytics software.

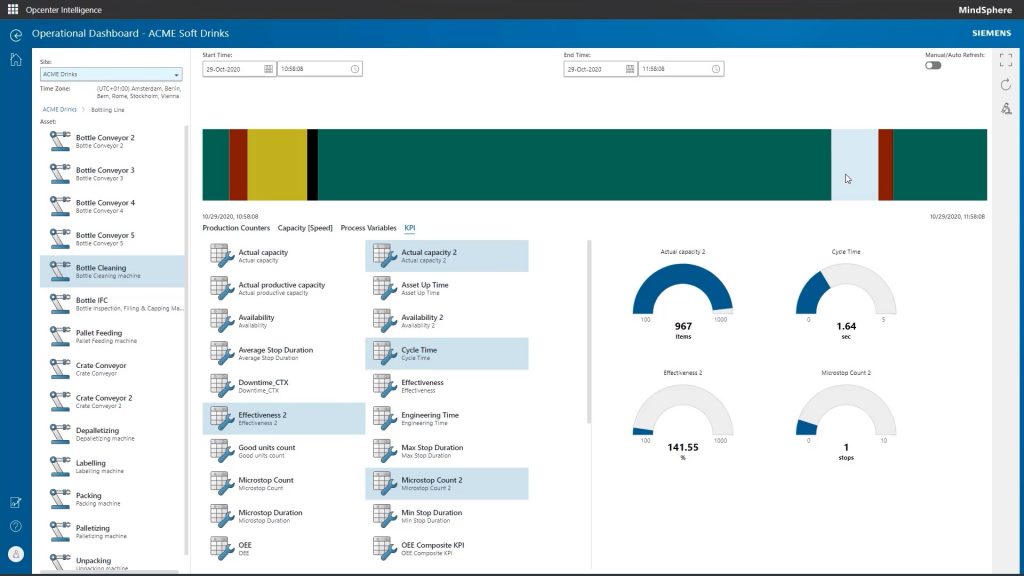

Data analytics can spot trends to help manufacturers make better decisions regarding maintenance, quality, and planning, and they’re able to make those decisions faster than ever before with all the data organized in a centralized location.

When combined with a manufacturing execution system (MES), manufacturers can accelerate their business and their production processes.

See what MES Opcenter Execution Discrete can do

How is data analytics used in manufacturing?

Big data in manufacturing can be leveraged to produce faster, more reliable machines, increase production line efficiency, and enable more automation across the entire organization.

Faster, more reliable machines

When machine and equipment manufacturers have transparency into how their product is being used on a day-to-day basis, they can compare how the machine is being used versus how it was designed.

Access to this data can provide valuable insight into how the next iteration of a specific machine is built.

Combining this data with simulation software and the digital twin, machine builders can use closed-loop validation to design and build a faster, more reliable next-generation machine.

Additionally, when a manufacturer knows exactly how a machine is operating through data analytics, they have a better understanding of the regular wear and tear individual parts experience, which can provide more accurate predictive maintenance.

Machine or entire production line shutdowns can be planned for the most optimal time, and maintenance can ensure all the right parts are ready.

Increase production line efficiency

It’s already challenging enough to see and understand all the inner workings of today’s complex machinery.

An entire production line is exponentially more complex.

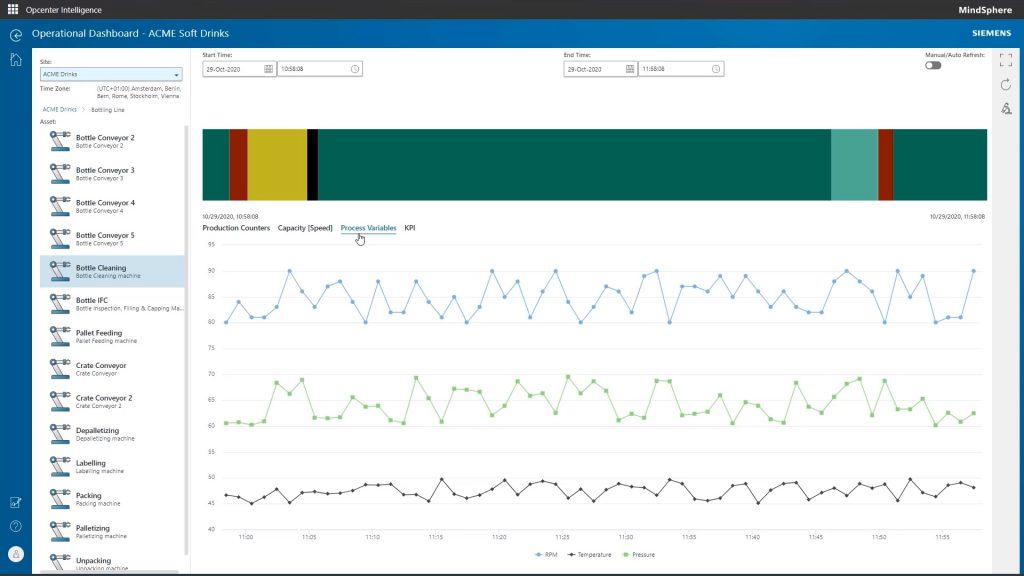

Data analytics can help make sense of everything and increase visibility with production-related data, whether it’s order numbers, personnel, materials, or something else entirely.

With an unobstructed view of the production line, manufacturers can find ways to rework scrap materials or gain insights into the true cost of production.

And with a complete data analytics view of the whole production line, manufacturers can react more quickly to production issues, which reduces downtime.

More automation across the organization

Industrial machinery equipment goes beyond the manufacturing floor.

Whether it’s standardized production processes across every plant for consistent quality or reacting more quickly to new conditions and requirements, data analytics and the right software tools can automate processes both on and off the manufacturing floor.

How manufacturers can benefit from data analytics

Data analytics provides real-time awareness for manufacturers.

When decision-makers can move faster with more accurate information derived from data analytics, companies are more competitive, customer satisfaction rises, product quality improves, and overall efficiency throughout the organization increases.

And as manufacturers gain a better understanding using available data analytics, the possibility for improvements is endless, ranging from improved energy efficiency to safer work environments and everything in between. Taking the first step toward harnessing data analytics can be a daunting one, but the end result – the digital factory and all its rewards – are well worth the journey.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io