The CAD Upgrade Picture

Productivity gains are key for manufacturing and engineering executives. More than 94% of survey respondents felt that their executives wanted at least some mechanical engineering productivity improvement.

CAD solution providers understand this and have packed productivity-enhancing features into their latest releases. Their efforts have not gone unnoticed. Eighty-eight percent of respondents felt that the new features in the latest two releases of their CAD solution had a high or medium impact on productivity. These software releases provide valuable new functionality for engineers.

Despite this, however, manufacturers rarely upgrade to the newest CAD software version right away. The need for training is one major reason for the delay.

To gain further insight into these issues, Lifecycle Insights conducted the CAD Productivity Study. This post will share findings from the study. It will also examine progressive approaches that can lower the cost and time commitment associated with training.

Training is an Impediment

Companies aren’t rushing to embrace the latest version of their CAD solution. One significant reason for this is the need for training on new enhancements.

Many of the new features in these releases could boost productivity. Engineers want to take advantage of these features. The CAD Productivity study found that 15% of respondents wanted significant training around new features. Meanwhile, 74% wanted moderate or some training.

Learning new CAD features takes time. This is true no matter which mode of training—free, paid, in-person, or remote—an engineer uses; but time is in short supply for engineers. They are already very busy trying to meet stringent design deadlines and solving critical engineering issues. If CAD training only takes place at a certain time, engineers could miss out on training entirely. So, CAD users often have to learn on the fly while they are using the new version of the CAD software.

Engineers are also unable to obtain the funding they need for proper training. Companies only have so many resources, and training is often not incorporated into annual budgets. Management may prioritize other needs over CAD software training. These factors prevent crucial productivity gains.

Approaches to Imparting Training

The study findings demonstrate that engineers want training but are unable to find the time and the budget for it. Yet, there are ways to overcome these obstacles.

There are a number of non-paid training resources available that fall into three main categories:

- CAD software documentation in the form of help and tutorials;

- online learning materials, blogs, videos, and articles

- online communities, forums, and knowledge bases that discuss CAD software.

It is important for companies to understand which option users prefer. The study shed some light here, as well.

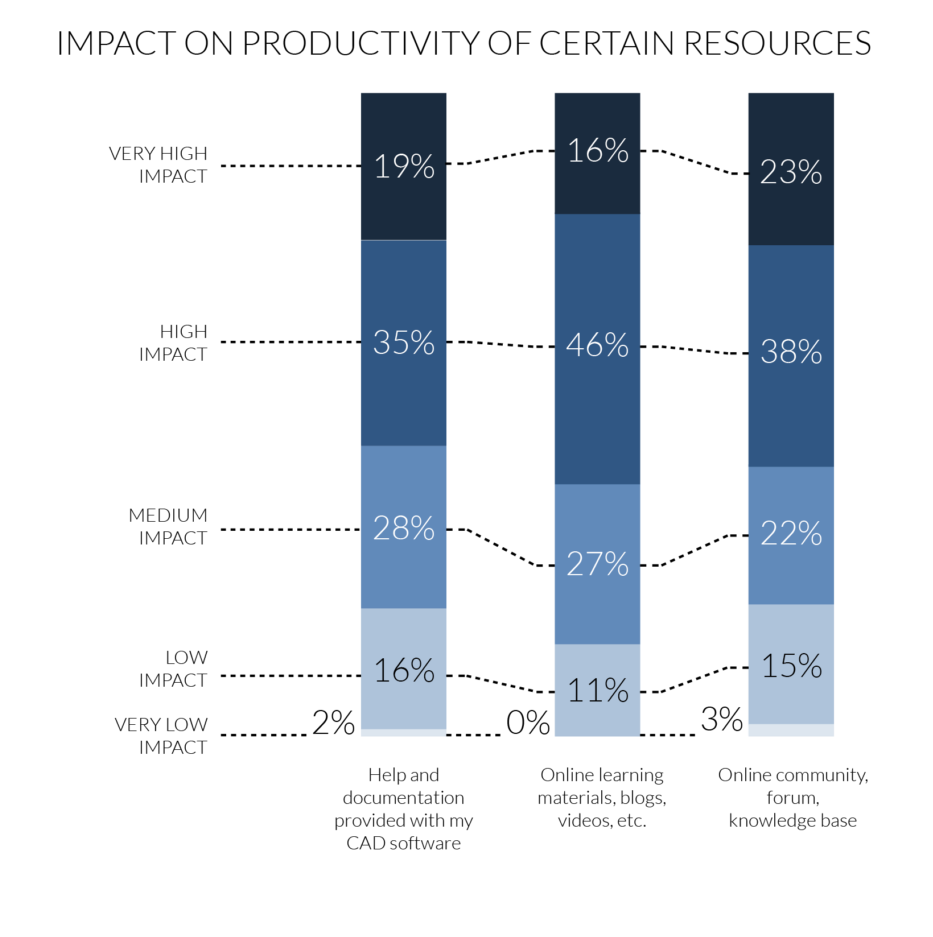

Online learning materials, blogs, and videos led the way, with 62% of respondents saying that using these materials had a high or very high impact on productivity. About 61% said that online communities, forums, and knowledge bases had a high or very high impact. Only 54% said the same of software documentation.

Engineers prefer online learning materials and online community resources to learn. This insight can help CAD solution providers to create more effective training resources.

Accessing Learning Materials inside CAD Solutions

Software documentation is meant for a generic audience, which explains why study participants deemed it the least effective training method. CAD solution providers know this, so they also host vibrant online communities to assist with learning new features. But the greatest opportunity for truly effective training is inside the solution itself.

Many CAD solution providers are using machine learning (ML) to curate and present training on new release features. Using this approach, the solution itself can continuously monitor a user’s patterns and analyze that behavior. Then, the ML algorithm can introduce engineers to new features that improve design productivity, right there in the solution. Users are more likely to adopt these new features when they don’t have to take time out of their schedules to do so.

Both online and offline learning materials can also be curated and made available in the CAD environment. Users can quickly learn how the new functions apply to the task they are working on without stepping away from it. And if they are interested in learning more, they can access the online resources. The online content enhances the ML-powered training within the solution.

Accessing learning materials inside CAD solutions is a progressive approach that saves both time and money. Engineers don’t have to make time to attend a training session on all the new features, many of which may not be relevant to them. Additionally, companies do not need to spend additional capital when the training is available to everyone on the CAD subscription.

Conclusion

Engineers need the training to reap the full productivity benefits of new CAD features. Lifecycle Insights’ CAD Productivity Study participants noted that they want to train on new features. Study findings showed that online resources and communities offer more effective training than generic software documentation.

While training is often relegated to the back burner due to time and cost constraints, these obstacles can be overcome. CAD solution providers have harnessed ML technology to provide effective training inside the solution.

Now, users can learn about the features most relevant to them without stepping away from their work. This approach improves engineering productivity without the need to allocate time and resources to lengthy, expensive training sessions. Online and offline learning resources allow CAD users to learn about new features. Machine learning in CAD software recommends new features while users are working on their designs. These training features drive productivity gains for engineering firms and manufacturers.