Organizations that once stored gigabytes of data now find themselves having to manage petabytes or even exabytes across their IT infrastructures. The borderless Internet, which allows applications to reach nearly anywhere, is one reason for the unprecedented data growth. Perhaps an even bigger driver is the increasing use of the public cloud for highly accessible

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Blog

SỐ HOÁ HAY LÀ CHẾT?

Chuyển đổi số hay là chết, nhiều chuyên gia quả quyết. Nhưng có doanh nghiệp “số hóa” rồi vẫn không mấy khá hơn. Dẫu thích hay không, ta phải thừa nhận, giới công nghệ đã thành công rực rỡ. Từ cái xác của bong bóng dotcom, chỉ hai thập kỷ, Amazon, Apple, Facebook, Google và

FROM PLM DATABASES TO PRODUCT DATA

Earlier this week, I shared my views about the future of data in PLM. Check this out here. Data is a foundational block for every organization, and it is an ultimate source of intelligence that can be used by manufacturing companies to improve their processes and products. Data is an interesting thing. Every person in a

PLM DATA ARCHITECTURE EVOLUTION FOR DUMMIES

This time of the year is a great opportunity to reflect on multiple topics. My article last week – PLM System Architecture Evolution for Dummies generated many comments and discussions online and offline. Thank you very much- you helped me shape my next blog to talk about the fundamental piece of PLM solution – data architecture

Production planning and scheduling at an Industry 4.0 level

What is required to achieve the best performance on the delivery of production at an Industry 4.0 level? The machines and equipment of cyber-physical systems are currently able to communicate their monitoring and control in real-time. However, there is not much benefit if each resource does not receive the instructions for the tasks to be

Smart Digital R&D labs to boost innovation for automotive and discrete manufacturers

The Chemistry and Advanced Materials industry played a leading role in previous industrial revolutions. It has supported the innovations across industries that have transformed our societies and lives over the past 150 years. Current and next-generation products like Electric Vehicles, drones, smartphones and tablets, flexible displays, high-speed internet, efficient integrated circuits, etc., all depend heavily on

Helping Red Bull Racing Achieve Efficiency, Consistency, and Cost-effectiveness

To attract new teams and ensure the sport’s viability, Formula 1® is revising its rules. Cost caps are being introduced to enable closer competition between large and small teams and promote financial sustainability across the sport. The 2022 season will bring drastically different technical regulations for Red Bull Racing and other teams; these rule changes

Solid Edge Wiring and Harness Design

Using Siemens SolidEdge Wiring and Harness Design, you can: ✔️increase wire harness manufacturing efficiencies through automation of the design-to-production process ✔️ eliminate the need for costly prototypes by using digital mockups ✔️collaborate on electrical design to increase productivity With a wide range of features and benefits, the Solid Edge software can assist in transforming your

Industrial Network Cybersecurity: Debunking the Myths and Adopting Best Practices

Industry 4.0 or the Industrial Internet of Things (IIoT) are no longer buzz words. Many different industries, including manufacturing, consumer and retail, energy and utilities, automotive, and the telecommunications sector, follow the IIoT trend. In particular, manufacturers embrace the IIoT faster than many other sectors, indicating the tremendous impact the IIoT and the realization of

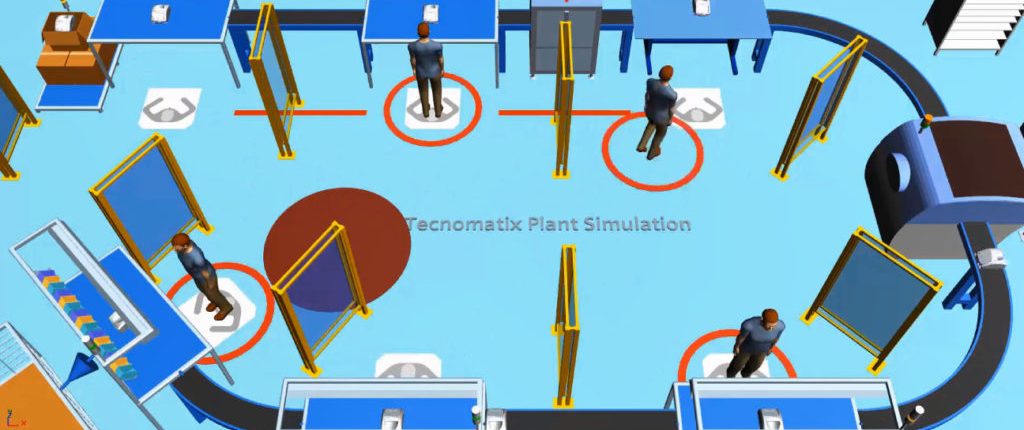

Digital twins, AR/VR bring simulation benefits to industrial automation users, says Siemens

Among the challenges that COVID-19 posed to manufacturers in 2020 was the need to plan for and maintain optimal production levels without sacrificing employee safety. As manifested in simulation and robotics, the convergence of digital and physical worlds provided tools for industry to adapt and even thrive in difficult times. Two sets of technologies can