6 Secrets you must know to increase sales using PLM

The basic economic principle, i.e. Production Possibility Curve (PPF) as shown in the example below tells us that the only way to get more output using same resources is by increasing productivity using technology or other means. You might have already invested in CAD and ERP tools for the same reason in the past. In this blog, we will see how Product Lifecycle Management supported by digital transformation can increase your sales at various lifecycle stages and how the benefits outweigh the cost of PLM by a huge margin.

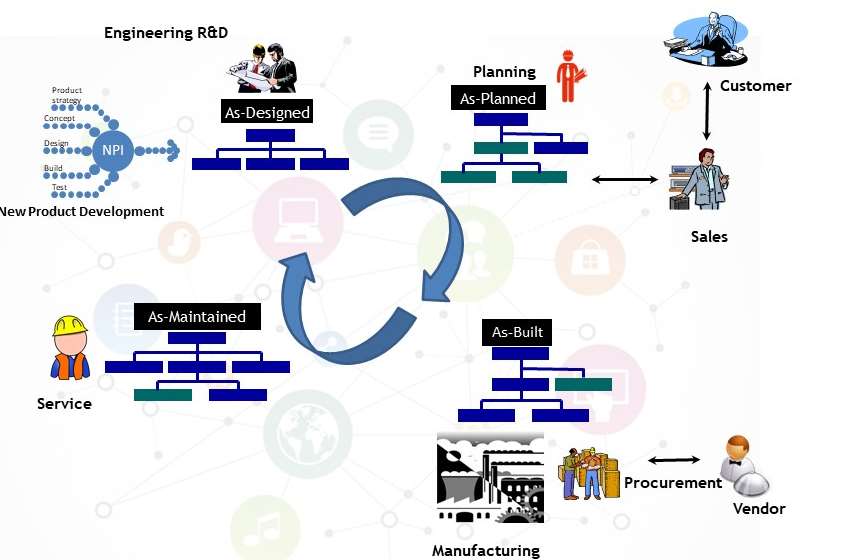

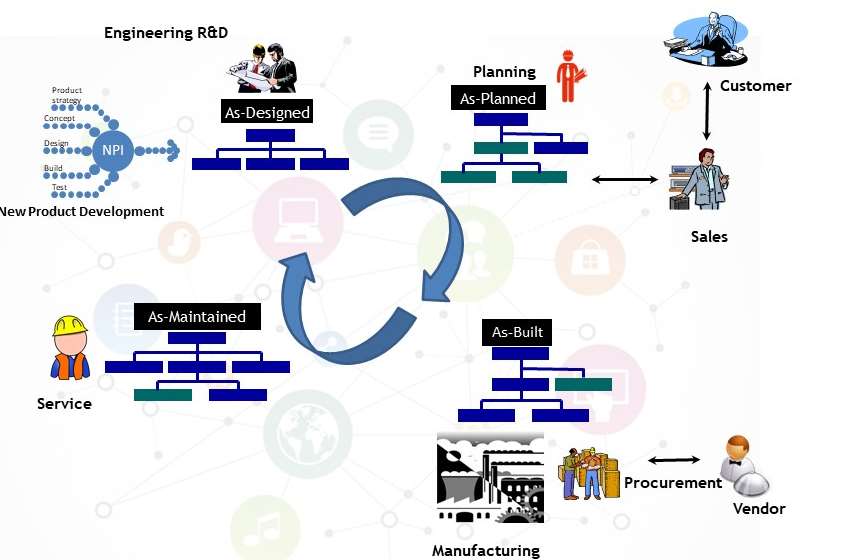

What is PLM (Product Lifecycle Management)

PLM is both a process and a system to manage the product from birth to retirement efficiently. PLM manages and integrates product data, processes, systems, and people so that you make maximum use of resources, produce the highest quality at minimum cost. PLM2.0 makes use of digital transformation technologies to leverage your PLM.

How PLM increases sales?

We will follow the various stages a customer undergoes to buy your product. Some of the stages may or may not be relevant for your business.

1. Customer Enquiry stage

a. More product variety with the same resource

Customer needs a more and more personalized product. Greater the variety, better is the chance to satisfy the customer. But the product variety comes with increased cost. PLM provides functionalities to manage variants and options efficiently. The so-called 150% BOMs capture all variations in a model/type/category and gives control over product portfolio. Sample example of such a configuration is shown below.

b. Less Price

The price of the product is mostly determined in design stages depending on the material used, functionalities implemented, parts and methods chosen, options and variants etc. All this information is captured in a PLM system and should cost goals can be set for a product and implemented. A good collaboration between departments like design, engineering, production and purchasing can help reducing procurement costs. PLM gives them a common platform and rigour to follow concurrent engineering processes which helps reduce costs. PLM Workflows makes people follow the steps and easily identifies bottlenecks. PLM improves reuse of parts which dramatically saves costs.

PLM2.0 opportunities: Big data analytics of part data can help segregate parts based on usage, category, features and help increase reuse and bring down supplier costs. Analysis of change objects, NCRs, problem reports can identify bottlenecks. Chatbots and AI-based search can increase the productivity of employees.

c. Online Sales portal /configurator

Sending inquiries and waiting for days for the price is the thing of the past. The customer wants the ability to see the various combinations and related costs to decide. This is a clear advantage if your product can be configured online and shown to customers or dealers to get a price idea. Feeding such a configurator without PLM system is both risky and unmanageable. Product configurator in PLM system can be easily mapped to sales configurator to display design options as custom options. A sample of the connection process is shown below.

PLM2.0 opportunities: Chatbots can help convert customers 24X7. The AI-based algorithm can help in estimating engineering hours based on previous data. Customer chosen options can be captured in wish mode to know customer demand.

2. Quote Stage

Your end sale is dependent on how efficient and fast you are after receiving customer interest. For engineered to order or make to order or services, this is especially important given the uncertainty in specs. Automation of technical specs generation and other documents like a preliminary BOM can dramatically speed up the sales process. A well-connected PLM system is necessary to do this. Many times, there is a dependency on calculations, and again the system can improve the response rate by helping reuse as much as possible. PLM by its workflows processes with automated emails and reminders, enforces a good collaboration between sales and engineering, which is key to success.

3. Build Stage

PLM provides the right recipe to build your products. If the recipe is wrong then no matter how efficient are you in production or how advanced machines you have, the product will fail. Especially if the product has changed under build stage due to a change in customer requirements or problems or deviations etc. Change management is at the heart of PLM and ensures that right change notices are implemented on the right products. Effectivity by date and lot are managed effectively by PLM & ERP integration. How to build information, latest drawings, 3D models and technical documents available in PLM provide a single point of truth to staff on the floor and avoids confusion. PLM provides the platform for early collaboration in new product development process to bring in design, manufacturing, procurement and other departments on the same page. Mobility solutions like web-based access, tablet or mobile clients make it easy for all to access data to discuss and resolve issues. All the above goes into reducing the cost of production and improving quality for the customer.

PLM2.0 opportunities: If you make a digital twin of your product at this stage, it saves a lot of physical testing times, enables the capture of data on connected digital twin. Copies of a digital twin can be made for customer-specific orders/changes and maintained. Smart Factory can help plan production process efficiently.

4. Delivery / Commissioning stage

Preparation of customer manual can be faster if content management along with PLM system is used to get live update information from parts, assemblies and other PLM data. Providing an online customer manual has a big advantage to provide updates, corrections and most important, having connected with the customer. An up to date AS-BUILT & AS-MAINTAINED helps service engineers to know exactly what is installed at customer place and helps them to deliver faster increasing customer satisfaction and increase re-sell. Spare parts management linked to PLM also increases response time and increase spare parts sales with the same staff.

PLM2.0 opportunities: Virtual commissioning saves a lot of time and efforts before actual commissioning by uncovering potential problems early.

5. Product Operating / Life stage

The cost of acquiring a new customer is always high, given the sales, marketing, and other overheads.

Repeat Sales:

PLM 2.0 can help in increasing upsell, cross-sales, spare parts, and service revenue in several ways. If you create a digital twin of your product and get key data logged from the field, then you can identify problems and initiate preventive maintenance. You can make use of life data to improve on the design and provide replacement/upgrade to the customer. These digital transformation tools will dramatically increase customer engagement and will help in repeat sales and better products.

Service:

If service is an important part of your business, then a service lifecycle management will increase efficiency for service engineers many times. They can access live as-maintained BOMs and update it as they replace parts. Spare part orders can be automated by linking to masked actual part numbers in Engineering BOMs and saved time can be used to win more customers.

Product quality and Change Management

PLM help make your product your brand ambassador and customers trust your brand. PLM system helps you ensure product quality at every stage by defining an efficient process and workflows. If your product is complex, the changes can easily lead to problems and reduce quality. PLM system has excellent inbuilt Change management capability. You can record all changes to the product in terms of Problem Report (PR), Change Request (CR) and Change Notice (CN) to manage changes. They can be derived from each other and helps to capture the content as well as intent for change. All changes can be traced back to the origin and cost of change also can be calculated. A comprehensive end to end change follow up process can be set, which can ensure that all changes/releases to parts and BOMs flows through all departments and actions are taken. A closed-loop quality workflow can be defined for the release of new designs. Documentation related to each step can be attached to change objects (PR, CR, CN) and also parts and assemblies giving a single source of truth for all. The quality process can be embedded in the PLM system to remove the dependency on the person or departments. All these ultimately makes your product foolproof against defects and human errors.

PLM2.0 opportunities:

Analysis of change data can give important insights into product and help improve areas where the problem occurs frequently.

6. Retirement / Disposal Stage

There might be compliance requirements for hazardous materials or capturing the end of the life characteristics or refurbishing or exchanging some parts. Service can help the sales department to identify and offer newer and better replacements. The customer might be interested in more fuel efficiency or maintenance cost or compliance with newer emission requirements. PLM truly helps manage the product till the end of life. PLM2.0 opportunities: If the connected digital twin exists, then all the data till the end of life can be used to make a better and more reliable product.

Source: PLM Nordic

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io