What Is NX Mold Connect | Siemens Xcelerator as a Service

With the announcement and launch of Xcelerator as a Service (XaaS), companies of all sizes are now empowering their designers and engineers with best-in-class software and services. These cloud-based solutions are flexible, scalable and allow access and collaboration from anywhere, at any time, and from any device.

As we begin the New Year, it is the perfect opportunity to spend some time talking to someone close to NX Mold Connect — a new SaaS product — and how XaaS is impacting customers, what they’ve seen regarding Software as a Service, and new ways to think optimistically about the year ahead.

What is NX Mold?

When you look at everyday products, they’re manufactured from plastic using a molding approach. Those molds are manufactured by taking a powder or liquid and effectively injecting it into a shape which then becomes solid. So, the plastic forms the shape, and that becomes the product you eventually see, touch, feel and use.

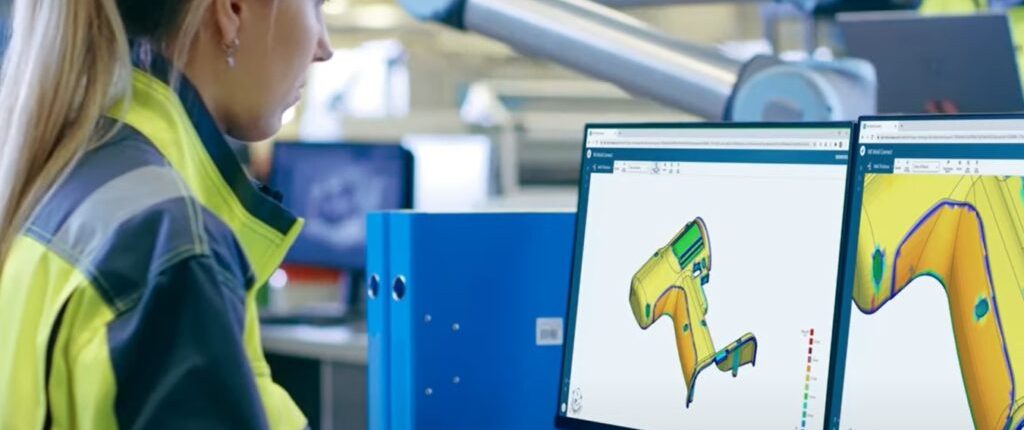

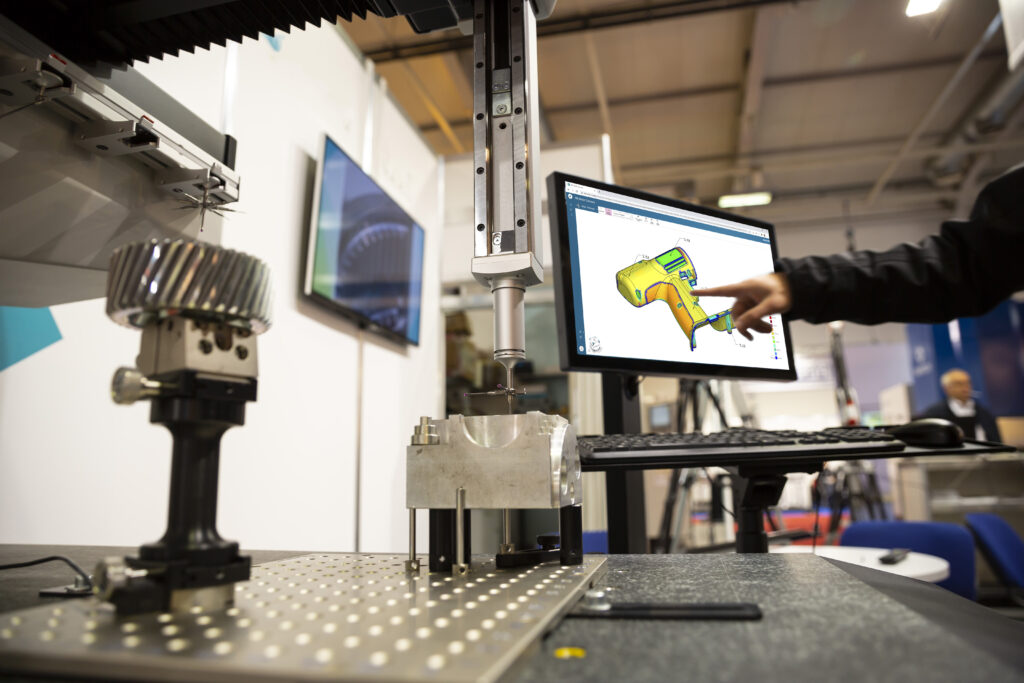

NX Mold Design automates and streamlines the entire mold development process including part design, tool design and motion validation. It allows users a fast response to design changes and high-quality molds.

That process of taking what the object should look like as a design, and then developing the tooling which injects the plastic to make the shape, is what molding is all about. “The key element here, particularly for these cloud solutions and what we’re doing next, is helping customers get better at costing up and quoting how much it’s going to cost them to make the tool that makes the thing that you touch,” says Paul Brown, Senior Marketing Director, Product Engineering Software at Siemens Digital Industries Software. “And that’s really what mold is all about. It’s about creating the thing that allows you to get the product that you have in your hand.”

Why Xcelerator as a Service and NX Mold Connect are important

“I think the big thing really for the process is to try and bring more people into the cycle,” Brown shares. “Now, particularly at the moment, we are focusing on a solution called NX Mold Connect, which targets the cost estimation analysis – the early part of the process.”

He notes that cost analysis can be a big challenge for mold makers because it is critical for accurate quotes. “If the analysts quote too high, they lose the business. If they quote too low, they lose money. So they want to get as accurate as quote as they can.”

NX Mold Connect was created for a salesperson or senior project lead, not a fulltime CAD designer who uses NX, a product in the Xcelerator portfolio, which delivers the next generation of design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin. The salesperson or project manager will analyze a design sent in by a prospective customer and look at feasibility of manufacturing.

Mold Connect users will use the system off and on — this means scaling when needed and the flexibility to have access only when they need to.

“That’s the benefit of having a cloud-based solution,” Brown says. NX Mold Connect supports the ability to have a temporary solution without the burden of paying for something when not in use or having to keep skill sets up. Brown adds, “Because the users are casual, it’s more about how easy is it to access it and how easy is it for them to do their job.”

He continues, “Users are not designing molds so they don’t have to worry about all of the design tools. They’re more concerned with doing their job quickly and efficiently – communicating and sharing information with their perspective customers and with the rest of their organization.”

The impact of Software as a Service on NX Mold Connect

“XaaS and the whole impact of the moment is gradually growing,” Brown states, although he recognizes that there is still a lot of room to grow in Software as a Service. “The world still has a lot of desktop-based solutions. The beauty of XaaS is it allows people to operate the way they want without completely uprooting and moving to a SaaS environment. They are able to work in a mixed environment with both on premise and on cloud solutions.”

Brown believes that NX Mold Connect’s ease-of-use, flexibility and accessibility to those who need it when they need it provides great value to having a XaaS solution.

The New Year: a time to reflect on the future

The New Year brings new opportunity for people to think about the future and how they want their development process to evolve.

“This is not about ‘out with the old and in with the new’ — this is about what next steps you should make. Now is the time to start thinking about those next steps and what you what can you do differently to make a difference. And it’s a perfect time to start looking,” says Brown.

Now is the time for customers to start looking at new approaches to embrace what is going to make life better or easier to build for the future.

“I think that’s where things like NXX, which will be available soon as a hosted service solution, and Mold Connect, will allow users to think differently and provide the opportunity of how they can get more from their systems.”

Looking ahead to a bright 2022

“When you look at the month ahead, I think, ‘well it’s all up from here.’ Living in the UK, January is probably the dreariest month we get. It’s just gray and wet and you look at it and think – but on the other hand, it will soon be February and everything is heading upwards. We’re now getting through the darkness, and it won’t be long before we’re back into Spring again”

You need the cold, cloudy days of January to appreciate the rest of the year and, if there’s one thing we’ve learned about cloud, it’s often the best solution that leads to brighter outcomes.

Additional resources:

Discover more benefits to Xcelerator as a Service (XaaS)

Read this blog for more information on NX Mold Connect

Learn about openness and how it impacts everything from collaboration between both internal teams and external suppliers. Read What does openness mean?

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io