How do you drive part re-use?

The answers to many engineering questions lay “hidden” in your enterprise data. We offer new help to answer questions that pertain to 3D data. We offer new help when that question pertains to 3D data.

Typical questions are:

- How should I manufacture a part shaped like this?

- Which of my suppliers offer items like this one?

- Do products we manufacture use parts like this and could we standardize it?

- What price did I pay last time I bought a part like this?

These questions are part of a recurring theme. There is a need to search for 3D parts. The exact names of these parts are likely to be unknown.

Traditional search is based on a keyword which is why it wouldn’t work. So we know that the established search methods are not helpful.

What we need is to add shape as a search criterion.

3D shape search overcomes the limitations of traditional keyword-based search. 3D shape search will find similar parts even if one person calls it a fastener while another person calls it a clip.

It will find a part even if its name was misspelled or left blank.

What’s the value of 3D shape search?

Sometimes the goal is just to find a similar part. Early in the design process an engineer can use even a coarse shape to find a finished part. These kind of re-use has enormous value and fights part proliferation. Even using an existing part as a starting point has significant value and is a very subtle way of promoting best practices.

Beyond part re-use

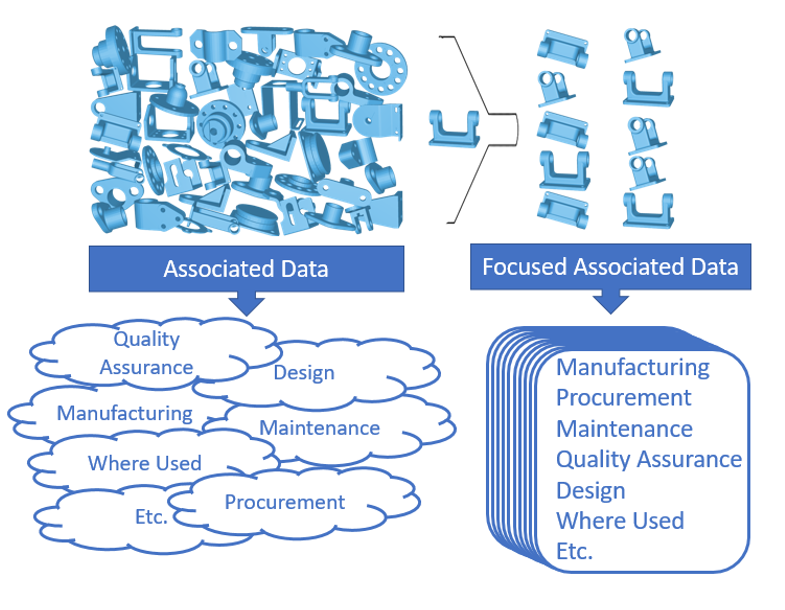

Every part has associated data.

Scattered

Over time, users make similar parts or buy similar parts but have no way to connect them because they were created/bought by different people in support of different projects. So just as the parts are scattered, so is the information – cost, projects where used, design/manufacturing know how, quality test results, work instructions etc. – associated them.

“What is a good thickness for this part?”

“Is there a good bolt group for fixing this item?”

Asking the right questions will help you have fewer changes in the downstream operations.

When you know two parts are alike a world of possibilities opens!

What about the associated data?

The value of shape search is not just the ability to find a part. Think about the associated data!

For example, the data needed to answer the questions at the top of this article.

As mentioned, answers to many engineering mysteries lie in the enterprise.

The follow on sentence is that the data is associated with 3D intellectual property and it is scattered.

When you have a set of shape search results the associated data for the topic of interest is now much more easily collated and browsed.

Teamcenter manages your parts and your data. Geolus Shape Search provides another way for that data to be collated and displayed in Teamcenter clients.

Geolus Shape Search is structured as an add-on component which means that Siemens Partners and Independent Software Vendors can contribute to the experience of providing additional insight into your business.

On March 30, there will be a Webinar on Geolus Shape Search and the Teamcenter clients that offer shape search.

We will also welcome T-Systems, a long time software development partner who will show how they have extended the reach of shape search into their products.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io