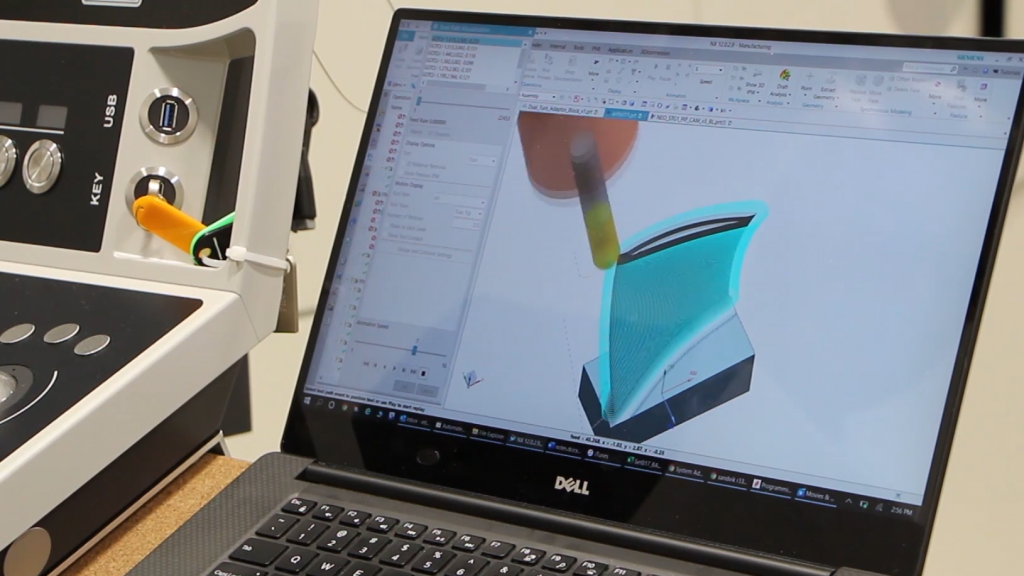

The company uses Siemens’ technology, including Sinumerik controllers and NX CAM software, to provide machining solutions that utilize the digital manufacturing capabilities.

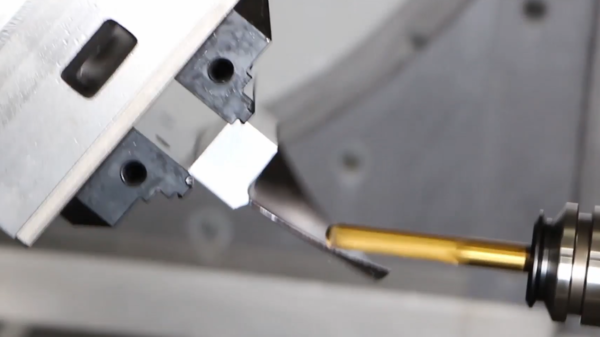

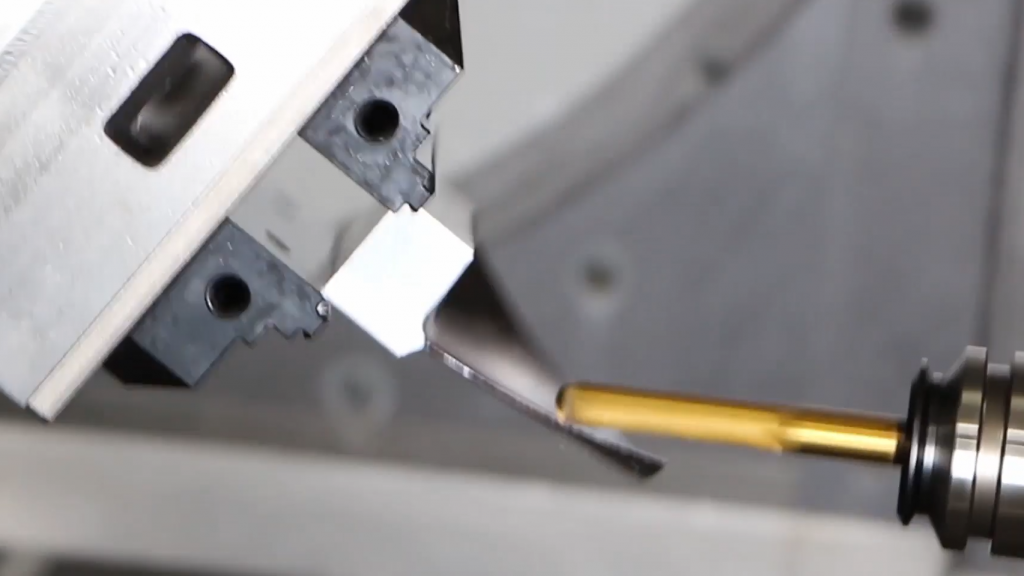

The founder of SIXDIGMA, Edwin Gasparraj, gives a video demonstration on how they combined three digital technologies to machine a complex airfoil. You will learn how:

- Advanced toolpath technologies in NX CAM significantly improve surface finish.

- Complex 5-axis probing accurately locates the part without special fixturing.

- Closed-loop adaptive machining validates workpiece surfaces and automatically modifies individual toolpaths to machine to very high tolerances.

You will also learn the process behind manufacturing a complex airfoil, with NX CAM at the forefront of the process. The software provides comprehensive and advanced NC programming capabilities that are necessary to generate complex toolpaths to machine excellent surface finish on tight tolerance parts.

Read A Digital Approach to Machining Better Parts today and watch the accompanying 12-minute demonstration by SIXDIGMA to learn how digital manufacturing powered by NX CAM allows you to standardize processes, shorten lead time, and improve part quality.