I had a conversion earlier this week about the BOM revision process. I used the abbreviation “FFF” in my response and got a question – what is FFF? This magic abbreviation is often used in manufacturing – FFF, and it stands for “Form, Fit, Function). If you never heard about it until now, take some

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Teamcenter | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

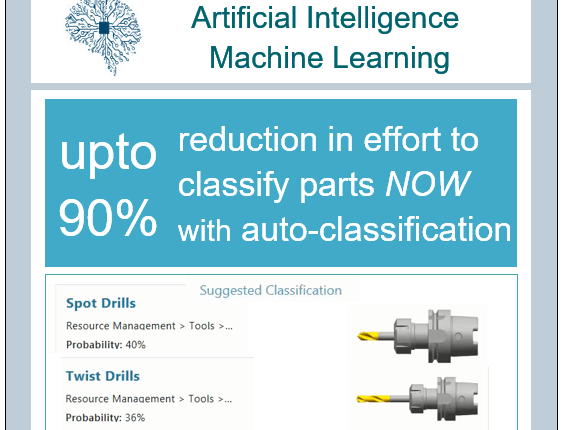

Classification AI ‘makes the system work for you’

In today’s highly responsive global markets, manufacturers in every industry need to focus on increasing their innovation rate, keeping costs low, and bringing their products to market faster. Manufacturers need to get the most out of every object and process they use while designing their products. To do this, they need to find all of

Product Outsourcing: Are you taking advantage?

“Do what you do best. Outsource the rest” Peter Drucker (Author, Management Consultant, Educator) If there is one business model that is ubiquitous across every industry, it is product outsourcing. Although the oldest form of outsourcing dates to the 18th century, with the shipping industry outsourcing work to local crew members, the advent of information technology

Digital Transformation Accelerates Ventilator Production in South Africa

How the Council for Scientific and Industrial Research Transformed Manufacturing Practices to Combat COVID-19 With the COVID-19 pandemic taking a huge toll on lives worldwide, a multidisciplinary, multiorganizational South African team was able to design, develop, and produce 18,000 ventilators within the span of 3 months. This amazing success story was possible because of the

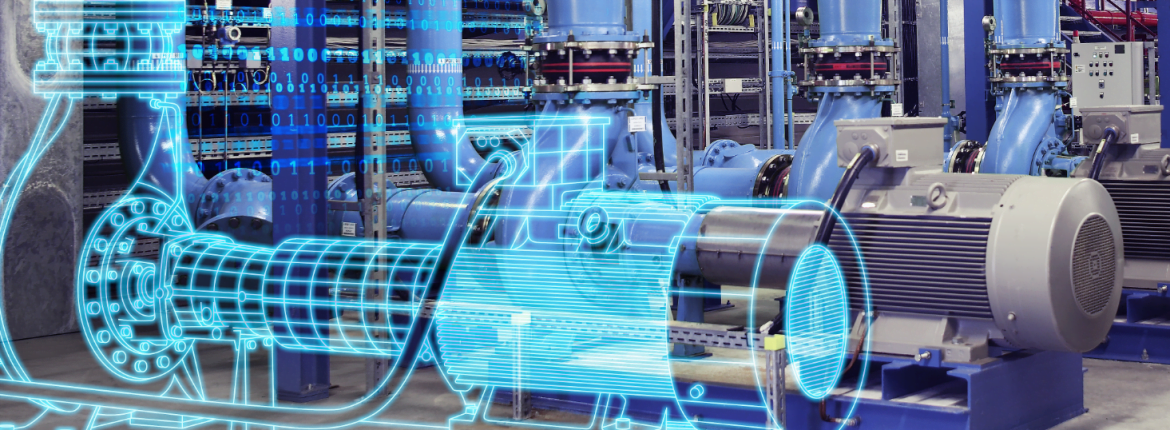

Are manufacturing data management practices converging with plant engineering?

This new decade has brought forth a complex set of challenges as it relates to industrial plant engineering. With increased market volatility, disrupted supply chains, and a push towards more sustainable production, process & discrete manufacturers seek more operational efficiency through new technology and through the prioritization of projects where their plants can be relocated,

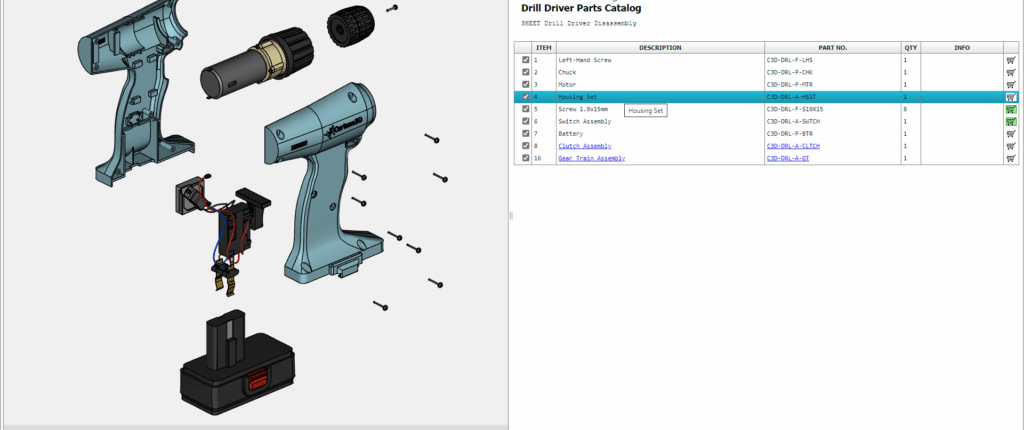

What’s New in RapidAuthor 13.1 and Connector 7.1

Highly descriptive technical publications can be very profitable, especially when they help manufacturing and service teams be more productive. RapidAuthor for Teamcenter extends your investment in engineering design data by reusing that content directly in the product documentation. This release of RapidAuthor for Teamcenter introduces many useful features, including: Formula Editor is available in all

Forrester Wave™ PLM Report Recognizes Teamcenter as a Leader

I am very excited to announce that in The Forrester Wave™: Product Lifecycle Management for Discrete Manufacturers, Q1 2021 report, Teamcenter is recognized by Forrester Research as a leader in PLM, with Siemens receiving the highest scores in the current offering and market presence categories and tying for the highest score in the strategy category.

With autonomous technology on the rise, how can automakers face the transformation?

There is a clear trend in the market for driverless automotive systems: the direction is upwards. Autonomous vehicle (AVs) sales are expected to rise sharply after 2030, with an estimated $7T market worth by 2050. Autonomous technology is becoming a reality, but the automotive industry will need to undergo a radical transformation in product development to deliver

Getting started with product data management

Investing in a product data management (PDM) system gives you control over your product and process-related data in a single environment that can be used anywhere and by anyone within the business. Once the system is in place you have the opportunity to expand into a full product lifecycle management (PLM) system. Benefits of a

The impact of poor asset information handover

The lifecycle of a plant or facility can be upwards of 50 plus years! During this time, the facility will undergo many projects – from yearly turnarounds and small retrofits to a major capital expansion. At any one time, an operating facility can have up to 500 projects on the go. It could be as