The lifecycle of a plant or facility can be upwards of 50 plus years! During this time, the facility will undergo many projects – from yearly turnarounds and small retrofits to a major capital expansion. At any one time, an operating facility can have up to 500 projects on the go. It could be as small as changing a pump or repairing a vessel, or it could be much larger, like a $1B debottlenecking project. So, what is the impact of poor asset information handover at the end of your brownfield or greenfield capital projects? The answer is the loss of significant capital expenditures (CAPEX) and lost labor productivity & equipment availability.

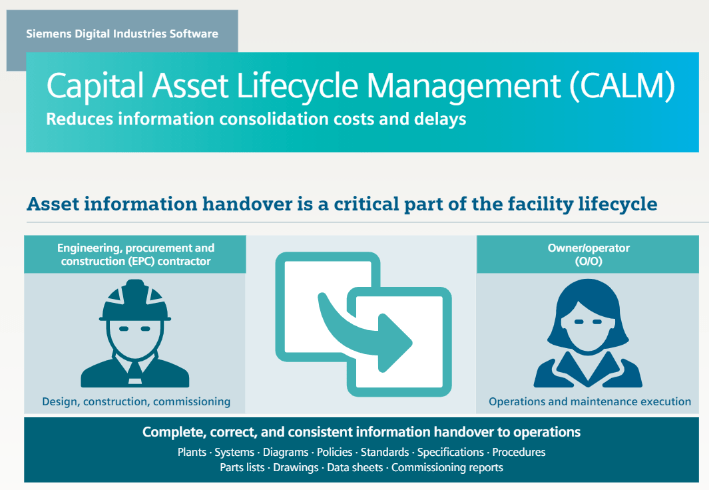

Studies from the industry group, FIATECH, in the early 2000s found that facility Owner-Operators (O/O’s) spent an estimated 2-4% of the project cost to manually correct and key in required operations and maintenance (O&M) information into their O&M systems, such as their ERP, CMMS and/or EAM system. In a $300M project, this equates to $6-$12M of hidden data entry and validation costs! One of the primary drivers behind this cost is the occurrence of a single “data dump” of information by the contractor at the end of the project. The good news is that the same FIATECH studies showed that with a periodic, more automated handover methodology, it is possible for O/O’s to save 60% of those costs.

Now, let’s turn our attention to the impact of poor asset information handover on your equipment availability. Availability relies on the field maintenance crew’s ability to implement and execute effective maintenance strategies – such as condition-based maintenance or reliability-centered maintenance. These strategies rely on data integrity and consistency to increase equipment uptime. When equipment is flagged for maintenance work, crews need to react quickly. With the confidence that the equipment information is up-to-date, the availability of spare parts is accurately represented. The work order clearly provides the scope of the work to be performed & how to complete it. A computerized maintenance management system (CMMS) or enterprise asset management (EAM) system will help with most of these aspects but only if there is a continuous digital handover methodology to ensure new project information is properly incorporated and made available.

A 2019 McKinsey and Company report found only 25% of wrench time (direct maintenance activity) at the surveyed power plant added value! That is astounding. Contributing to this is that facilities are constantly evolving, highlighting the importance of managing this change and automating the processes that help keep your CMMS/EAM system a trusted source of asset information to support direct maintenance activities. The same Mckinsey report identified that value-added wrench time could be doubled by automating repetitive work like data entry or verifying system trends! Combining this type of field maintenance process automation with a streamlined and automated “continuous digital handover” methodology is critical to addressing the loss of CAPEX budget defined earlier and addressing OPEX issues around productivity and the resulting equipment availability.

Want to learn more about Siemens’s ability to automate these processes? Start your journey by checking out our latest infographic below.

Don’t hesitate to contact Thanh for advice on automation solutions for CAD / CAM / CAE / PLM / ERP / IT systems exclusively for SMEs.

Luu Phan Thanh (Tyler) Solutions Consultant at PLM Ecosystem Mobile +84 976 099 099

Web www.plmes.io Email tyler.luu@plmes.io