Switching from the ubiquitous 2D drawing to a modern 3D representation of your Production layout has its costs, but the benefits can outweigh them Why design production layouts in 3D? Most of our readers are aware that 2D drawings were once prevalent in Product Engineering. Car design, for example, was recorded on 2D drawings. In contrast,

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Tecnomatix | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

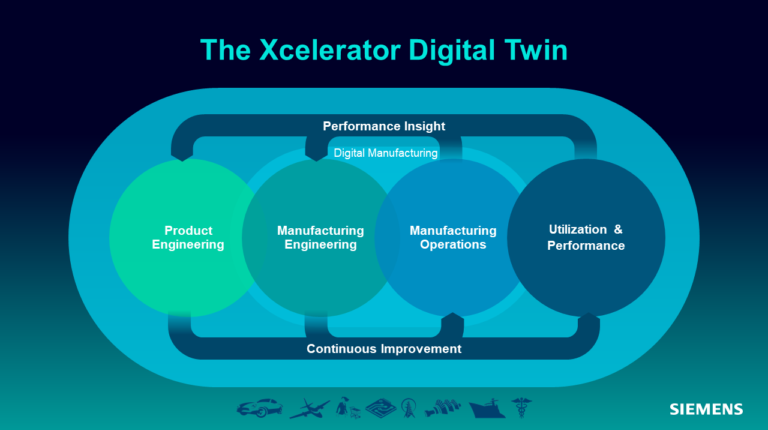

Continuity of the Digital Thread in Manufacturing

This is the second in a series of blogs where we discuss the requirement for detailed manufacturing engineering and operations orchestration today and the potential benefits that can be realized by utilizing Digital Manufacturing solutions. —– Production excellence is achieved with a digital thread connecting product engineering through product production all the way to product

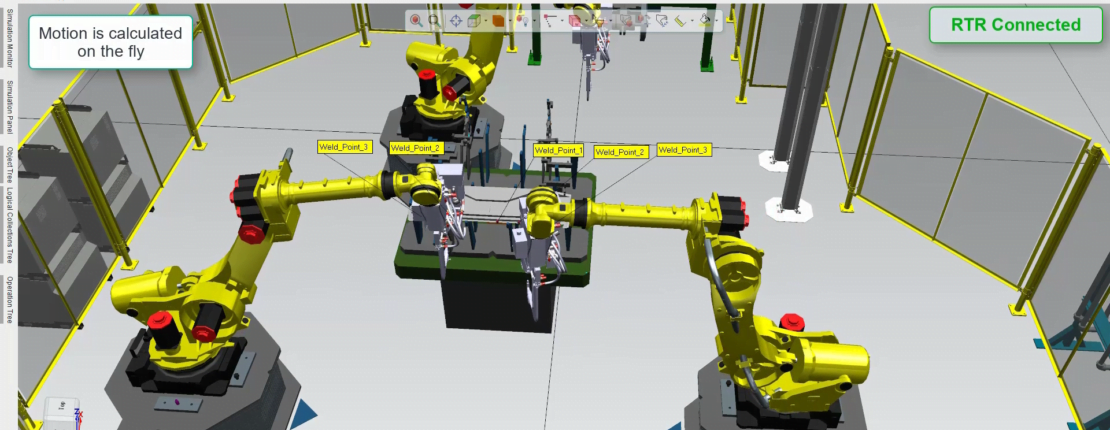

Valiant TMS shows benefits of Siemens and Realtime Robotics partnership

Recent proof of concept with a global automotive line builder shows significant savings in the engineering time required to program multi-robot systems. Valiant TMS participated in a proof of concept with Siemens Digital Industries Software and Realtime Robotics (RTR) which showed that RTR’s technology seamlessly integrated into Tecnomatix Process Simulate software simplifies robot programming and

Achieve a flexible and dynamic environment with Process Simulate

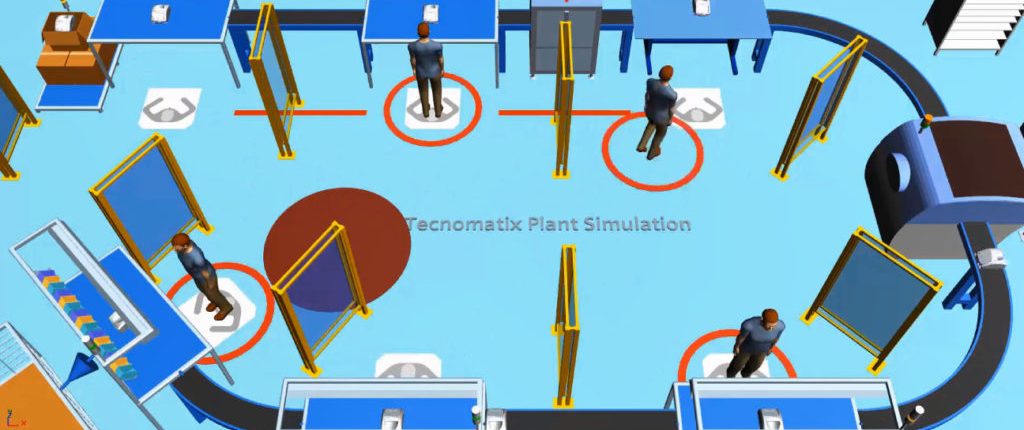

In this Process Simulate demonstration video, Matrix Production’s primary goal is to achieve a flexible, dynamic environment, which allows fast response and easy adjustments to updates, new product introductions, and more. This new innovative concept includes: A separation between the production environment to the logistics chain. Instead of having conveying systems and other “hard” automation types of

Digital twins, AR/VR bring simulation benefits to industrial automation users, says Siemens

Among the challenges that COVID-19 posed to manufacturers in 2020 was the need to plan for and maintain optimal production levels without sacrificing employee safety. As manifested in simulation and robotics, the convergence of digital and physical worlds provided tools for industry to adapt and even thrive in difficult times. Two sets of technologies can