One thing that frustrates us most here at Siemens, is when you, the customer, design…

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Industry 4.0 | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

Driving digital transformation in robotics engineering

Robots are without a doubt an integral part of the future of manufacturing. But robotics manufacturers face several challenges, such as increasing demand for flexible, intelligent automation, higher device complexity, and an increasing focus on performance and reliability.

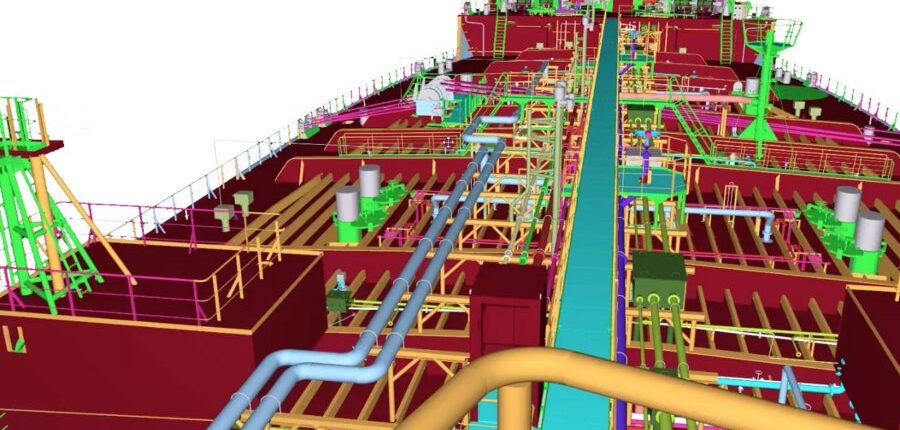

Siemens enters agreement to purchase FORAN software to expand capabilities in marine design and engineering | NX Design

Siemens has entered into an agreement to purchase FORAN software to expand capabilities in marine design and engineering. FORAN is CAD/CAE/CAM software for the design, construction and engineering of vessels and marine structures. This will enable Siemens to better support marine customers in digital transformation, with a focus on meeting Shipyard 4.0 and sustainability goals…

Applying computer vision in automated factories | Thought Leadership

Using artificial intelligence and computer vision to design, realize, and optimize automated factory robots.

Leveraging digitalization to accelerate production lead time and secure the quality of traceability – The MicroPort case

High performance is critical. MicroPort CRM (Cardiac Rhythm Management) is a business unit of MicroPort Scientific Corporation that manufactures pacemakers, implantable defibrillators, pacing leads, and Holter monitors for patients with cardiac rhythm disorders. MicroPort CRM’s solutions are Class III products, which means they are strictly regulated by regulatory authorities and must have the highest level

IoT: the enabler of digital transformation

As you may have noticed, the Internet of Things (IoT) has become a key talking point in recent years. And for good reason. By connecting devices to collect and share data, IoT is one of the strongest enablers to accelerating digital transformation. If you need to improve your factory’s production capacity and the maintenance of

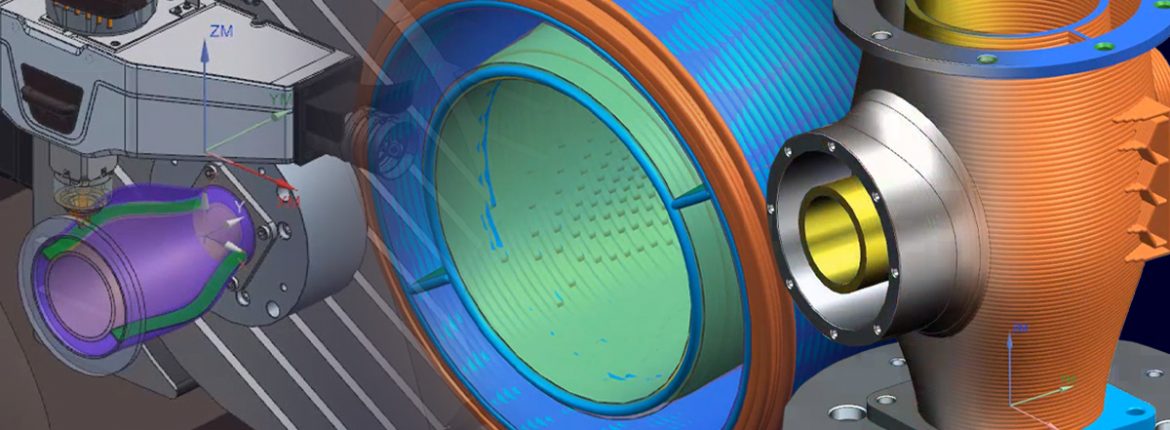

Advancing Additive #12 – Powering a Multi-axis AM Operation

The overall CNC market is projected to grow over the next six years at a seven percent compound annual growth rate. This is largely due to the growing demand for more multi-axis machines. And one of the fastest-growing segments of the multi-axis market is hybrid manufacturing. In fact, the market for additive/subtractive machines will grow

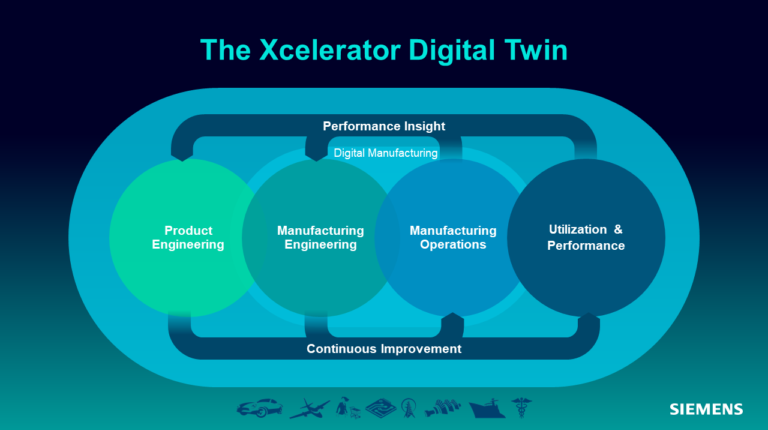

Continuity of the Digital Thread in Manufacturing

This is the second in a series of blogs where we discuss the requirement for detailed manufacturing engineering and operations orchestration today and the potential benefits that can be realized by utilizing Digital Manufacturing solutions. —– Production excellence is achieved with a digital thread connecting product engineering through product production all the way to product

Production planning and scheduling at an Industry 4.0 level

What is required to achieve the best performance on the delivery of production at an Industry 4.0 level? The machines and equipment of cyber-physical systems are currently able to communicate their monitoring and control in real-time. However, there is not much benefit if each resource does not receive the instructions for the tasks to be