- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

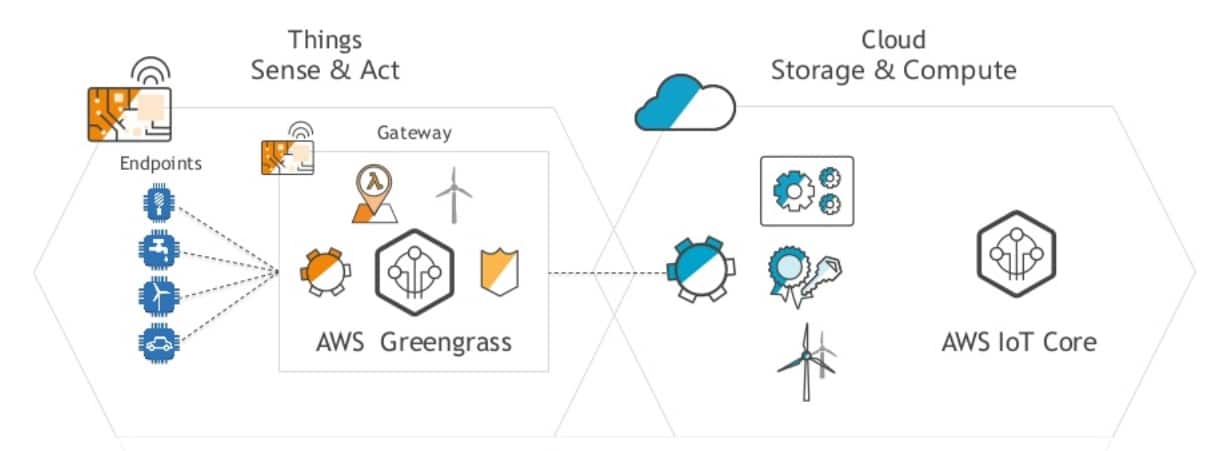

AWS IoT Greengrass

AWS IoT Greengrass core is a software that provides cloud capabilities to local Edge devices. Multiple Edge devices can be connected to each other over the same network to make sure that device to device , device to sensors and sensors to devices communication happening correctly. AWS IoT Greengrass core helps Edge devices to collect, manage and analyze data closer to the source of information(sensors and actuators), react automatically to local events, and communicate securely with each other on local networks. AWS IoT Greengrass developers can use AWS Lambda SDK to work with Lambda functions and prebuilt connectors to create event-driven serverless applications that are deployed to Edge devices for local operations.

AWS IoT Greengrass makes it possible for customers and developers to build IoT devices, applications and their logic to run locally on the Edge Devices to make it event-driven. This also provides the same flavor of cloud capabilities to run Application logic’s on the Edge Devices locally with the help of Lambda functions. In AWS IoT Greengrass core installed devices securely communicates on a local network and exchange messages with each other without connecting to the cloud.

This provides a local pub/sub message manager that can intelligently buffer messages if connectivity is lost so that inbound and outbound messages to the cloud are conserved. With the help of secure authentication and authorization, AWS IoT Greengrass make sure that your data is always safe and once the device gets connected to cloud the device data then sync to cloud.

In AWS IoT Greengrass provides Local machine learning inference to prepare Local ML models to make the Edge device more powerful.

For an Example – In case of Ore Mines, where you don’t have good internet connectivity, AWS Greengrass can really help you to build a complete eco system on the top of Edge Devices where you can perform different event-driven serverless operations and also you can write Machine Learning Models for continuous monitoring of basic equipment’s required for workers to work on such hazardous environment.