- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

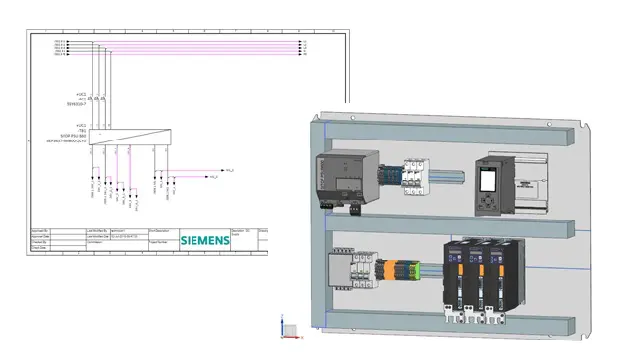

Industrial Electrical Design Boosting engineering productivity with the next generation of Electrical Design for production systems

Industrial Electrical Design

Industrial Electrical Design

The complete design of production systems requires the design of their electrical systems. Our products enable the complete electrical design of machines and production lines in the integrated NX environment for the most efficient overall system design.

Electrical Design in NX is a one-of-a-kind electrical design tool, designed from the ground up to enable electrical engineers to complete their designs faster and with higher quality than ever before. It allows electrical engineers to work on the same backbone as their mechanical and software peers, allowing them to save time and eliminate errors.

Machine Electrical Design Capabilities

2D Schematic Design

The central task in Electrical Design is the creation of 2D electrical schematics. With Electrical Design in NX, you can complete these designs directly within the system in an integrated environment.

- Create 2D schematic drawings.

- Create interruption points

- Display and use cross-references

- Select catalog parts

- Leverage rules-based engineering to automate tasks

3D Cabinet Design

Electrical Design also provides integrated 3D cabinet design enabling fast and efficient cabinet layouting.

- Quickly place and move components

- Measure clearances

- Directly navigate to and from the 2D schematics

Functional Engineering

For the first time, electrical engineers can create a functional, model-based design.

- Define function, location, and product structures

- Create relationships between objects

- Reuse and combine data between objects to automate design processes

Incorporate Data From Upstream Process

Electrical engineers typically start their design with input from upstream processes. They need access to this data to do their work efficiently. With NX Electrical Design and Automation Designer incorporate this data in modeled form through import of:

- Mechanical assembly data

- Plant layouts

- P&ID Diagrams

- Excel lists

Provision of Data to Downstream Processes

After completing their design, electrical engineers need to communicate their work to their peers in automation so that the software can be written for the machine. NX Electrical Design can be extended to allow direct integration of PLC software and hardware in the data model and program-less export of this data directly to Siemens TIA Portal.

For 3rd-party systems, the creation of signal lists and hardware information is possible through custom reports and excel export of data from the system.

Rule-based Engineering

The quality of engineering designs often suffers from errors caused in non-value, repetitive activities. These actions, such as the definition of reference designations, symbolic names of signals or even the creation of schematics can be automated through your design rules. This allows engineers to reduce errors and gives them more time to focus on creating value and driving innovation.

Standard Reports

After completing an electrical design, the production system needs to be manufactured and that means providing manufacturing with the information they need. Standard reports are provided out-of-the-box to make the documentation complete, such as:

- Terminal Diagrams

- Bill-of-Materials

- Cable Diagrams

Templates

Improve the quality and consistency of your designs, by re-using them as design templates stored in the data backbone. These templates allow you to store the contents of a design and insert them into new designs as complete functions instead of single devices or symbols. Never design the same system twice.

Expanding the functionality to PLC software is also possible through Automation Designer.

Subscribe

Get the latest tips, software updates and promos.