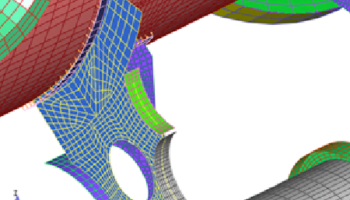

Femap can access geometry from all major CAD systems including Pro/Engineer, CATIA, NX (Unigraphics), Solid Edge, SolidWorks, and AutoCAD. After you import CAD data into Femap you can prepare the model for analysis using the easy geometry locator which will detect and display troublesome entities. Femap can completely remove troublesome entities, such as silvers, with the geometry cleanup tools or by suppressing them.

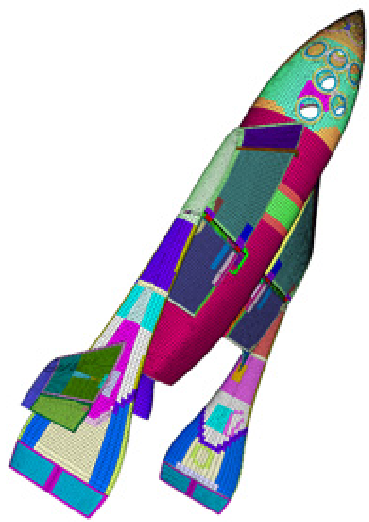

Using Femap’s digital simulation capabilities you can:

- Predict and improve product performance and reliability

- Reduce time-consuming and costly physical prototyping and testing

- Evaluate different designs and materials

- Optimize your designs and reduce material usage