- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

TANDEM PRESS LINE FOR AUTO

Tandem Press Line for Auto

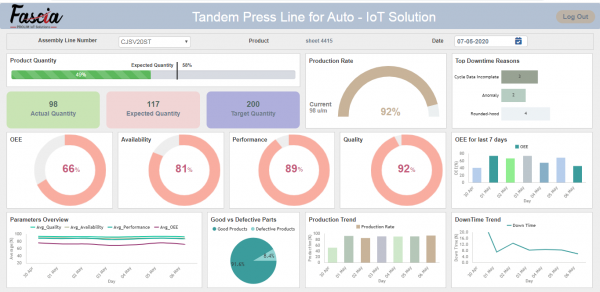

In today’s digital fast paced world, enhancing machine operational efficiency and productivity is what all the manufacturers strive for. IoT when implemented for manufacturing processes provides the executives a way to track the metrics and KPIs in order to derive useful insights on the processes and make decisions to improve the consistency, quality and productivity. The Tandem Press Line Solution includes machine monitoring and OEE data collection to increase the machine efficiency and productivity leveraging innovation. Overall Equipment Effectiveness (OEE) is considered as the benchmark for identifying losses, measuring the equipment efficiency that highlights the manufacturing productivity of an organization.

This solution designed by PROLIM measures the OEE helping management to gain important insights on how to systematically improve the manufacturing process and monitors the Key Performance Indicators (KPI) percentage calculation that uses equipment availability, productivity and quality metrics to calculate a value that summarizes how well the production line is operating.

The dashboard displays the primary reasons for manufacturing productivity losses which are:

- Availability: This KPI considers the time for which the equipment should ideally be available for production excluding any downtime.

- Performance: It is a measure of the net process or production cycle run time against its full capability.

- Quality: This highlights the count of manufactured parts that meet the quality standards, excluding parts that don’t meet the quality specifications.

- Overall Equipment Effectiveness (OEE) is a measure of how well a manufacturing operation is utilized compared to its full potential.

The dashboard also shows the following:

- Production Rate

- Actual units produced

- Expected units for production

- Target units for production

The OEE dashboard can also assist the management and the floor managers/supervisors in keeping a tab on the processes and the productivity of the organization as it displays:

- OEE Trend for a week

- Average of the Parameters

- Production Trend

- Good and Defective Products Count

The solution also has the feature that monitors the Down Time reasons and the Down Time trend as reducing downtime and predicting the next possible failure of machines can lower the maintenance cost, increase the production efficiency and minimize the down time.

Thus, the solution by embedding IOT in manufacturing processes using sensors and connected devices can completely transform the equipment performance as the IoT-enabled equipment can send alerts about the preventive maintenance requests leading to quick resolutions for reduced downtime, better performance and efficient productivity.

Subscribe

Get the latest tips, software updates and promos.

Disclaimer: I am the author at PLM ECOSYSTEM, focusing on developing digital-thread platforms with capabilities across CAD, CAM, CAE, PLM, ERP, and IT systems to manage the product data lifecycle and connect various industry networks. My opinions may be biased. Articles and thoughts on PLMES represent solely the author's views and not necessarily those of the company. Reviews and mentions do not imply endorsement or recommendations for purchase.