Data is everywhere these days, and I see more and more people taking data seriously when it comes to engineering systems’ business and organization. Back two decades ago, CAD file was a foundation of engineering data. In my life, it was AutoCAD, which became the first example of an engineering platform. AutoCAD files were ultimate

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

PLM | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

INTERCHANGEABILITY, REVISIONS, AND NEW PART NUMBER

My last week’s article about FFF (Form. Fit and Function) triggered many interesting discussions online and offline. Thank you all for coming back to me and sharing your insight and experience. Today, I want to continue the conversation and talk about another question I’ve been asked very often – creating a new Revision to the existing

Paperless Quality processes – save time and the environment!

Siemens Quality Management Solutions helps manufacturers manage a paperless process. A new product introduction (NPI) must proceed through different approval gates. How can this process unfold without recording each step and activity on hardcopy? Imagine you’ve been invited to attend a Failure Modes and Effects Analysis (FMEA) session. The facilitator organizes a meeting in which

Bridging PLM-EAM Gaps

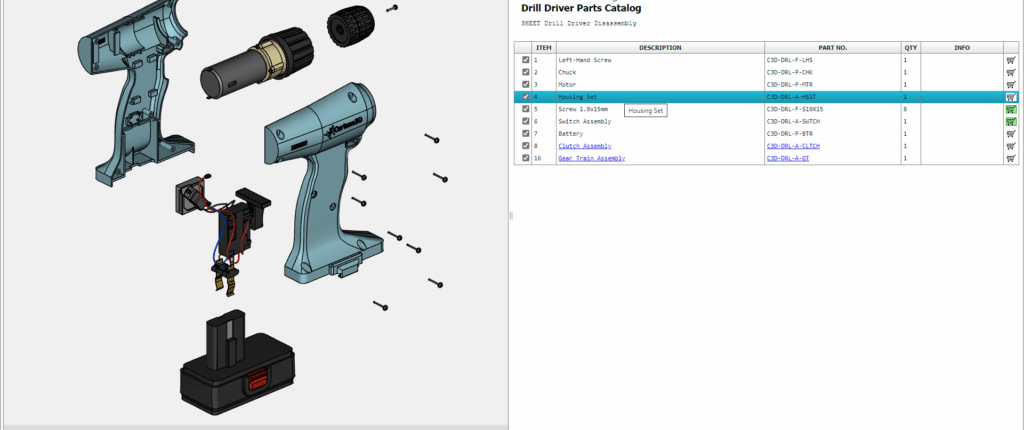

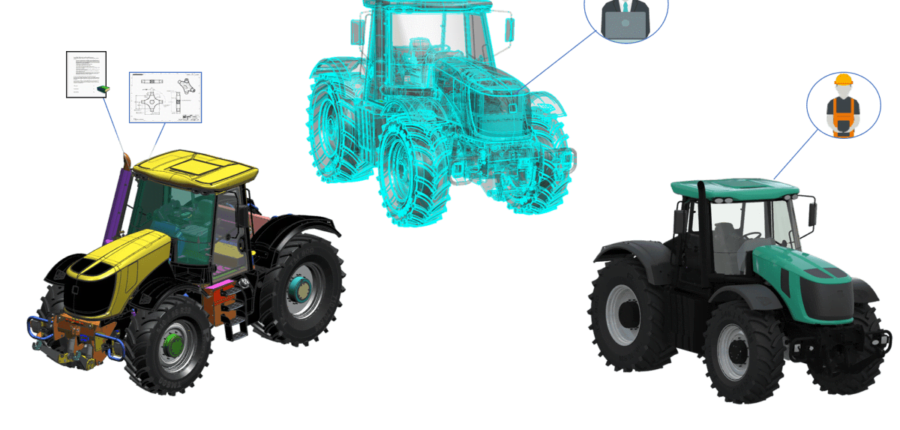

In many cases, when the maintenance activity is being performed, the technician uses the set of tools & replacement parts defined by the manufacturer as part of the product service plan. This is normally contained in a Product Lifecycle Management (PLM) system. In reality, this information could be out of synchronization in the Enterprise Asset

What Are Challenges With Today’s PLM Support?

Several companies today have set up a PLM solution for their existing engineering processes. It is safe to say that the strategy followed by implementation across functions is well-planned, documented, and communicated to all. But is much thought put into the post-implementation phase? How will your business maintain a PLM environment efficiently? After such a planned

FFF (FORM, FIT, FUNCTION). REVISIONS AND INTERCHANGEABILITY

I had a conversion earlier this week about the BOM revision process. I used the abbreviation “FFF” in my response and got a question – what is FFF? This magic abbreviation is often used in manufacturing – FFF, and it stands for “Form, Fit, Function). If you never heard about it until now, take some

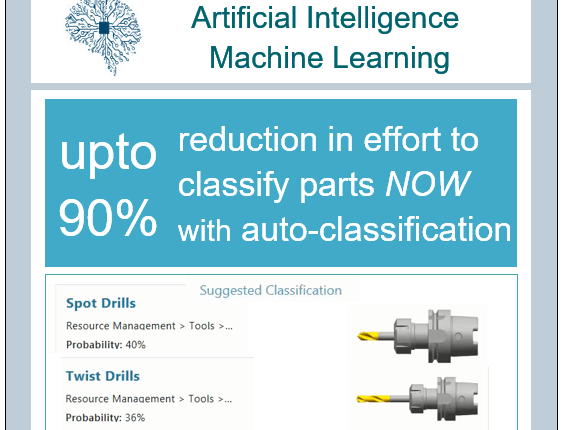

Classification AI ‘makes the system work for you’

In today’s highly responsive global markets, manufacturers in every industry need to focus on increasing their innovation rate, keeping costs low, and bringing their products to market faster. Manufacturers need to get the most out of every object and process they use while designing their products. To do this, they need to find all of

Streamline product compliance with complete traceability of chemical composition

Supplier declarations and product compliance Addressing product compliance regulations such as REACH, RoHS, Conflict Minerals, and California Prop 65 requires complete visibility into your product makeup, including material and substance data from your in-house and your supplied components. Without the right technology to help you automate the supplier declaration process, you could be at risk of noncompliance, costly errors, and

Product Outsourcing: Are you taking advantage?

“Do what you do best. Outsource the rest” Peter Drucker (Author, Management Consultant, Educator) If there is one business model that is ubiquitous across every industry, it is product outsourcing. Although the oldest form of outsourcing dates to the 18th century, with the shipping industry outsourcing work to local crew members, the advent of information technology

Extending BOM Software and the Drive to Digital

Effective & efficient bill of material (BOM) software is a key driver for continuous product success and to stay ahead of the competition. Customers often spend a significant amount of time reconciling BOMs across various home-grown applications, spreadsheets, and the like, usually disconnected. Unfortunately, this extra labor typically leads to inconsistent data and significant time