Using digital collaboration to achieve productivity and delivery goals When manufacturers are asked to characterize their supply chain today, resilient…

- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

Opcenter | Thanh PLM Tư Vấn Các Dịch Vụ CAD/CAM/CAE/PLM/IT Tại Việt Nam

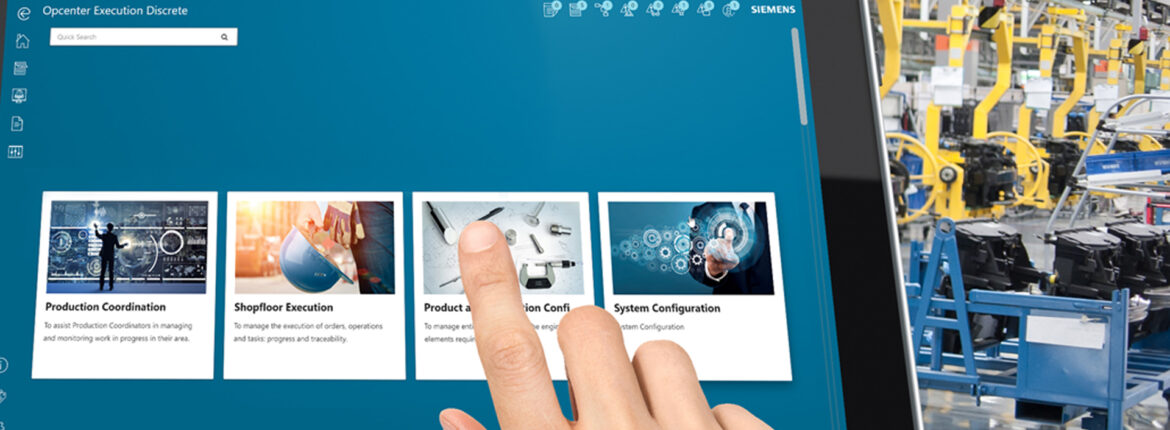

Manufacturing Operations Management (MOM) overcomes these 5 business challenges | Industrial Machinery

Manufacturing Operations Management (MOM) solutions make operations easier and improve business operations in these ways.

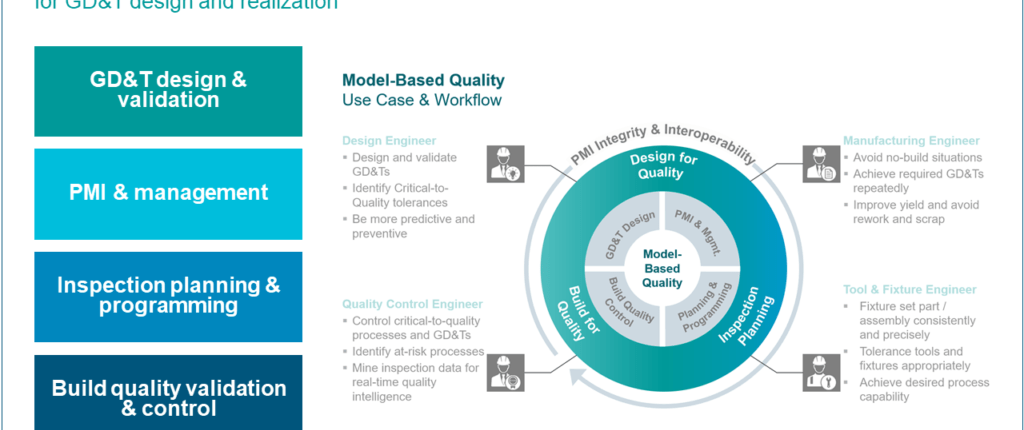

Model-based quality and the digital thread | Tecnomatix

Model-based quality helps manufacturers digitalize their dimensional management practices and achieve profitable quality.

Opcenter APS 18.5 has been released! | Opcenter

We are excited to announce that the latest version of Opcenter APS 18.5 has been…

Enhancing evaluation of potential risks with FMEA methodology

Design and manufacturing defects can have expensive and serious implications: amplified warranty costs, diminished product functionality and safety, and an incapacity to meet essential industry standards, among other potential consequences. The ability to evaluate risks associated with a possible product or process failure is essential. Failure mode and effects analysis (FMEA) is a critical tool

Leveraging digitalization to accelerate production lead time and secure the quality of traceability – The MicroPort case

High performance is critical. MicroPort CRM (Cardiac Rhythm Management) is a business unit of MicroPort Scientific Corporation that manufactures pacemakers, implantable defibrillators, pacing leads, and Holter monitors for patients with cardiac rhythm disorders. MicroPort CRM’s solutions are Class III products, which means they are strictly regulated by regulatory authorities and must have the highest level

Low code platforms augment manufacturing operations to accelerate digital transformation

In the past 18 months, we have seen a dramatic resurgence in innovation in the manufacturing sector. In addition, the unprecedented impact of the COVID-19 pandemic has created new urgency in manufacturing agility and resilience. Across industries, we are prioritizing the need to quickly adapt to supply and demand changes with minimum disruption and resistance.

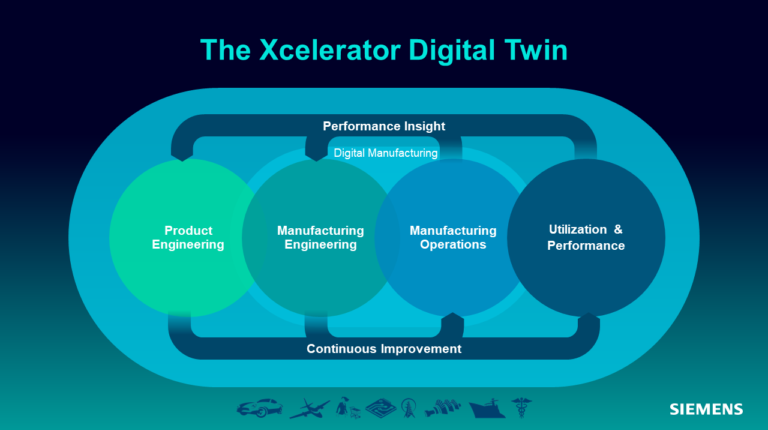

Continuity of the Digital Thread in Manufacturing

This is the second in a series of blogs where we discuss the requirement for detailed manufacturing engineering and operations orchestration today and the potential benefits that can be realized by utilizing Digital Manufacturing solutions. —– Production excellence is achieved with a digital thread connecting product engineering through product production all the way to product

Manufacturing Operations Management for manufacturing agility in modern times

With manufacturers seeking new ways to keep staff members separated from each other, the value of Smart Manufacturing takes on an added dimension. Learn the 3 key requirements for successful manufacturing in uncertain market conditions and how each benefits from MOM technologies for Smart Manufacturing With manufacturers seeking new ways to keep staff members separated