- Mon-Sat 8.00 - 20.00

- (+84) 976-099-099

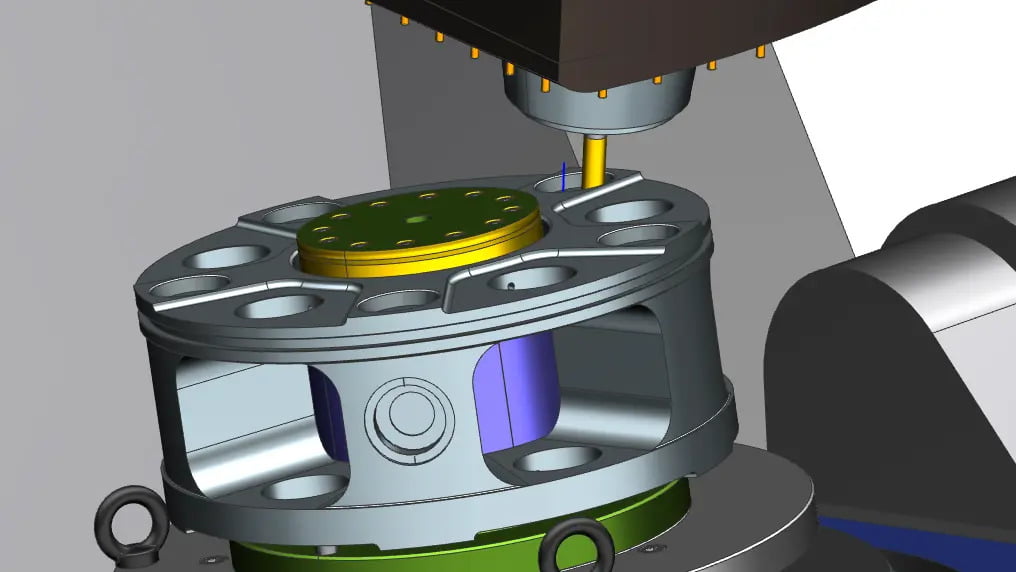

Gain efficiency using one comprehensive CAM software

CAM Software

Program any job using one software. CAM Software provides comprehensive and integrated NC programming capabilities in a single system. This enables the use of consistent 3D models, data and processes to seamlessly connect planning and shop floor operations with a digital thread.

You can streamline and automate NC programming, while reducing cycle time, using powerful, application-specific tools. From 2.5-axis machining and mold manufacturing, to simultaneous 5-axis milling and high-volume production, NX allows you to use one CAM software to make better parts faster.

Learn about advanced, integrated NC programming capabilities.

CAM Software : Complex Parts Machining

Create precisely controlled 5-axis tool paths to effectively machine complex geometries. Using application-specific capabilities, you can dramatically reduce programming time and create smart, collision-free cutting operations.

CAM Software: Mold, Die & Electrode Machining

High-speed machining, automated rest milling, and smooth finishing methods help you produce molds and dies with a near-mirror finish, while reducing lead time. Quickly design and program electrodes using an automated process.

CAM Software: Postprocessing & Machining Simulation

Generate machine-ready NC programs for a wide range of machine tools and controls with a postprocessor embedded in your CAM software. Leverage the digital twin of your machines and processes to accurately validate manufacturing operations to reduce setup time and maximize machine uptime.

CAM Software: Prismatic Parts Machining

Minimize manual input and create optimized processes to machine precision parts. Advanced technologies, such as volume-based milling and automated feature recognition, can reduce programming time by up to 90 percent.

[newsletter_form form="1" list="1"]