The identification of simulation model parameters is a cornerstone of modern systems engineering. Yet it remains a difficult process requiring expertise and substantial resources. That’s why we recently developed a new, innovative process based on Artificial Intelligence (AI) to speed up the parameter identification process. I want to show you how this AI-based process has been integrated into Simcenter Testlab Neo to allow identifying parameters with the click of a button. What is the best? You don’t even need to be an AI expert to use this new functionality. Let’s proceed to discover together how it works.

What is parameter identification used for?

Your company uses simulation models to predict the behavior of current and future versions of your products. It goes without saying that you want these predictions to be accurate enough. For that, you and your colleagues spend time correlating your models. One of the main tasks of the correlation process is the identification of model parameters to make the simulation predictions match the test measurements without tolerances.

As an example, for a vehicle drive-line torsional damper, the model parameters could be the torsional stiffness or damping.

Where does AI come in?

In a classical parameter identification process, the predictions from your model are compared to the corresponding measurements done on the physical prototype. Through a (time-consuming) optimization process, which takes place after the measurements, the parameters of the model are iteratively adjusted to find the best match between predictions and measurements. Once a good correlation is obtained, the uncertain parameters have been identified.

AI offers the possibility to radically change this process. Through AI learning techniques, the relation between the uncertain model parameters and the model predictions can be embedded into a neural network. As a result, the identification process is reduced to one execution (also called inferencing) of this neural network. The benefit is that the parameter identification produces results in seconds and in one click. No need to wait anymore for day-long optimizations to finish. If you want to know how to get or create such neural networks for parameter identification, please contact Siemens Engineering Services.

How does this AI parameter identification work in Simcenter Testlab Neo?

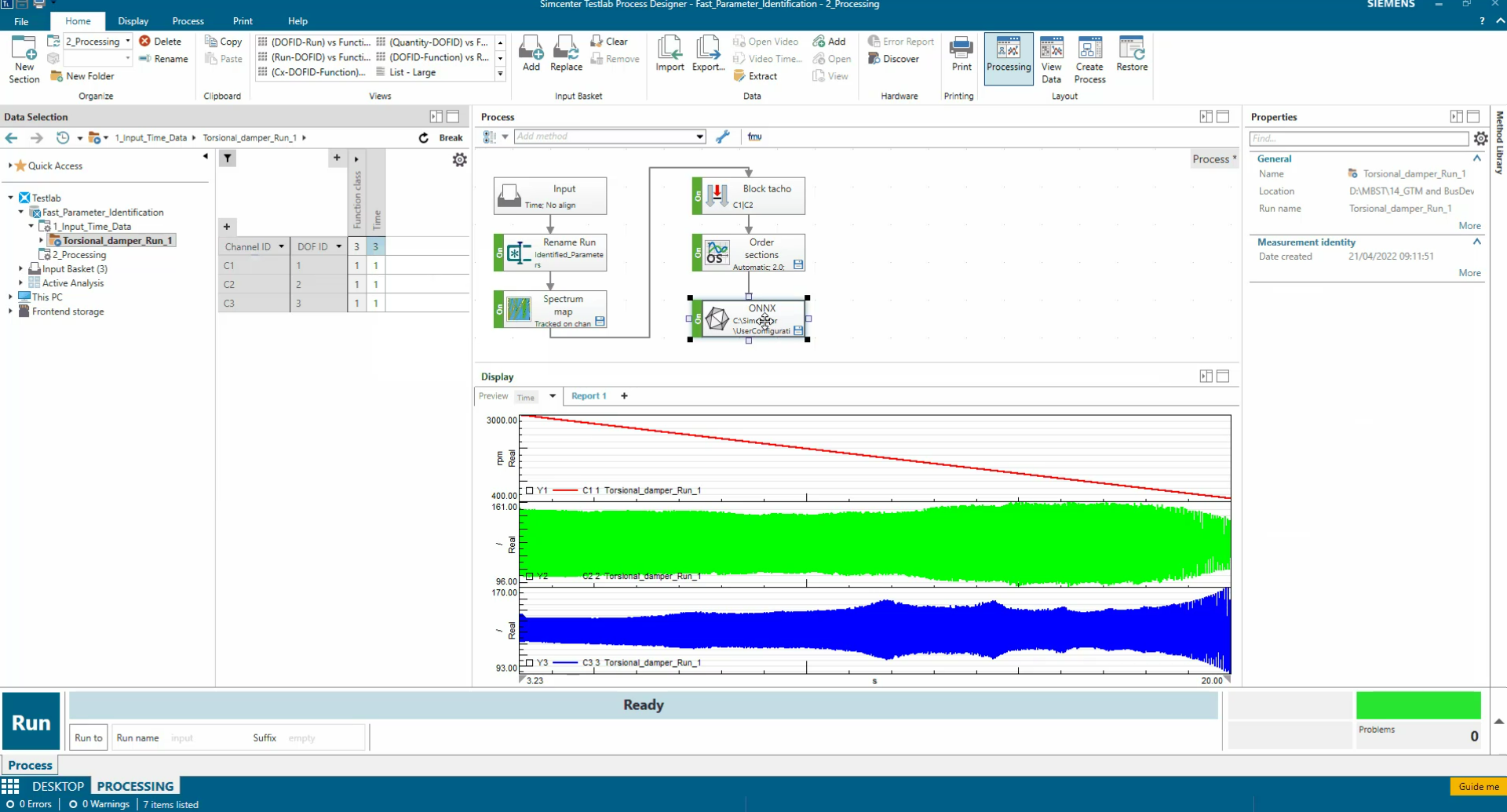

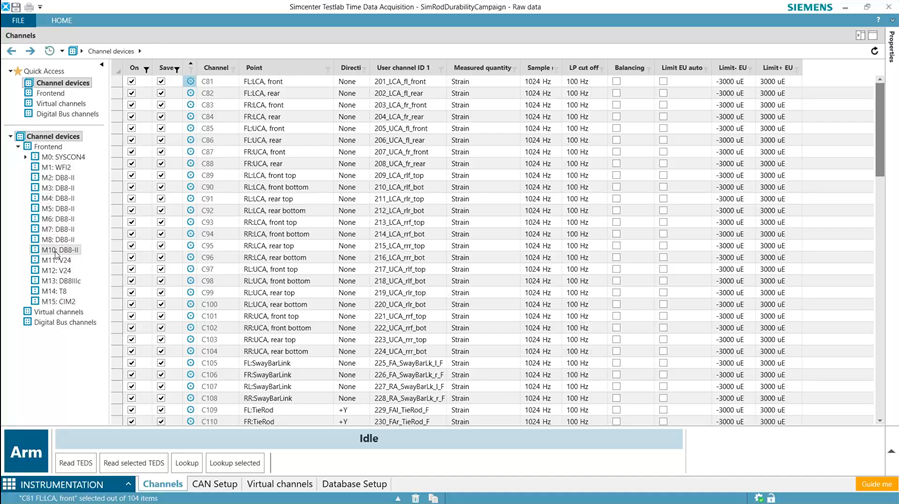

Once your physical measurements have been done with Simcenter Testlab and Simcenter SCADAS, for example on a test bench, you can go to Simcenter Testlab Neo Process Designer for the data post-processing.

ONNX

The AI identification process can be integrated into Simcenter Testlab Neo Process Designer via a new method called “ONNX”. ONNX is the most-used export format for neural networks. The AI algorithm is trained upfront using simulation data and is delivered to the test operator as a stand-alone block that can be used in any part of a process design. As a result, the engineer executing the test doesn’t need to perform dedicated processing or optimization but just feeds the Neural Network with the data coming from the acquisition.

This streamlines the identification process, as the parameters are immediately available after the test for the engineer to evaluate the quality of the estimation. For example, he can use them to check if the tests were performed correctly and if needed to repeat some of them, without the need to iterate with the CAE team. The process is also easy to deploy, as the complete estimation routine is embedded in one single software environment.

In a nutshell

The new ONNX processing method in Simcenter Testlab Neo 2206 allows you to identify the parameters of your simulation models in seconds and with ease. This enables your test engineers to quickly provide feedback to the simulation team, mitigating the issues of long estimation processes and time-consuming iterations when having to update CAE models.